Why Supply Chain Excellence Matters More Than Ever

Six sigma in supply chain management is a data-driven methodology that helps companies reduce defects, eliminate waste, and improve efficiency across their entire supply chain. It combines statistical tools with process improvement techniques to achieve near-perfect quality (99.9997% defect-free, or just 3.4 defects per million opportunities).

Key benefits of Six Sigma in supply chains:

- Cost Reduction: Eliminates waste and optimizes processes to lower operational expenses

- Quality Improvement: Reduces defects from an average of 10% to nearly zero

- Faster Delivery: Cuts lead times by up to 30% through streamlined processes

- Better Supplier Relationships: Creates data-driven collaboration with manufacturing partners

- Risk Management: Identifies and mitigates disruptions before they impact operations

Here’s a sobering statistic: 10% of orders in most companies have some form of defect. That’s one in every ten orders going out the door with errors—wrong products, damaged goods, late shipments, or incorrect quantities. For a Fortune 500 company processing millions of orders annually, that represents enormous economic loss and reputational damage.

Today’s global supply chains face unprecedented complexity. Companies manufacturing home improvement products in Mexico, automotive parts in Vietnam, or sporting goods in China must steer tariffs, geopolitical tensions, quality control across continents, and the constant pressure to reduce costs while improving delivery times. Recent U.S. Supreme Court decisions on tariffs have added another layer of uncertainty to offshore manufacturing strategies.

Six Sigma was originally developed by Motorola in the 1980s to combat manufacturing defects. But its real power emerges when combined with Lean principles—creating Lean Six Sigma. This dual approach tackles both defects (Six Sigma) and waste (Lean), making it especially powerful for optimizing complex, multi-country supply chains.

I’m Albert Brenner, co-owner of a contract manufacturer with over 40 years of experience helping Fortune 500 companies implement six sigma in supply chain management across our factory relationships in Mexico, China, and Vietnam. Our expertise in navigating challenges like tariffs and quality control has helped clients in home improvement, sporting goods, automotive, and outdoor products achieve significant cost savings while maintaining on-time delivery.

What Are Lean and Six Sigma Principles?

At its heart, Six Sigma is a data-driven, process improvement methodology that aims to minimize process variations and defects. Developed by Motorola in the 1980s, its ultimate goal is to achieve near-perfection, striving for only 3.4 defects per million opportunities (DPMO). Think of it as a relentless pursuit of flawlessness, where every step in a process is scrutinized to ensure it performs consistently and correctly. This statistical approach provides in-depth insight into quality control processes, helping us identify the root causes of defects and refine production.

While Six Sigma focuses on reducing defects, Lean principles are all about eliminating waste and streamlining processes. Lean thinking emphasizes identifying and removing any activity that does not add value from the customer’s perspective. Any complex, convoluted, or time-consuming process leaves more room for failure, opening up opportunities for human or technical error. By simplifying and streamlining these processes, we reduce the chances of errors and defects.

When we integrate the Lean method with Six Sigma analysis, we get Lean Six Sigma—a powerful synergy that addresses both efficiency and quality. This combined approach is particularly effective for supply chain optimization because it allows us to tackle both the prevention of defects (Six Sigma) and the reduction of waste and streamlining of operations (Lean). It’s about ensuring that our supply chain processes are not only defect-free but also as efficient as possible, always focused on delivering maximum customer value. For more detailed insights into the specialized language of manufacturing, you can always refer to our guide on manufacturing terminology.

The 8 potential wastes that can affect a supply chain, often referred to as the “8 Wastes of Lean,” are:

- Defects: Errors or flaws that require rework or lead to scrap.

- Overproduction: Producing more than is needed, or sooner than needed.

- Waiting: Idle time for people, materials, or equipment.

- Non-used Talent: Underutilizing employees’ skills, knowledge, and creativity.

- Transportation: Unnecessary movement of materials or products.

- Inventory: Excess raw materials, work-in-progress, or finished goods.

- Motion: Unnecessary movement by people.

- Extra-processing: Performing unnecessary steps or using inefficient methods.

By systematically identifying and eliminating these wastes, coupled with Six Sigma’s defect prevention, we can significantly improve supply chain performance.

Key Benefits of Implementing Six Sigma in Supply Chain Management

Implementing six sigma in supply chain management isn’t just about buzzwords; it’s about tangible improvements that impact our bottom line and customer satisfaction. It’s a strategic move that brings about a cascade of benefits, changing how we operate and compete in the global market.

Here are the key benefits we’ve seen our clients achieve:

- Improved Efficiency and Reduced Operational Costs: By identifying and eliminating waste and inefficiencies across the supply chain, Six Sigma helps streamline processes, leading to faster production cycles and shorter lead times. This directly translates to significant cost reductions. For example, optimizing inventory turnover means less capital tied up in warehousing, and reducing unnecessary transportation cuts logistics expenses.

- Improved Product Quality and Customer Satisfaction: Six Sigma’s core focus on defect prevention ensures consistent product quality. When we reduce defects from, say, 10% of orders to nearly zero, it dramatically cuts down on returns, rework, and customer complaints. This refined quality control builds customer loyalty and improves our reputation.

- Better Risk Management: Modern supply chains face increasing disturbances and risks, from geopolitical events to natural disasters. The Six Sigma framework helps us improve the awareness and management of supply-chain risk. By analyzing process variations and potential failure points, we can proactively identify and mitigate risks, making our supply chains more resilient.

- Stronger Supplier Collaboration: Six Sigma promotes a data-driven approach to quality and efficiency, which extends to our relationships with suppliers. When we work with our manufacturing partners in Mexico, China, or Vietnam to implement Six Sigma principles, we establish clear quality standards and performance metrics. This collaborative effort, often supported by tools like supplier scorecards, improves process quality, builds trust, and fosters stronger, more reliable partnerships. For us, building strong buyer-supplier relationships is paramount to successful offshore manufacturing.

- Scalability and Sustainability: By standardizing processes and optimizing resource use, Six Sigma helps us create more sustainable supply chain practices. This not only reduces environmental impact but also ensures that our supply chain can scale effectively as our business grows, handling increased demand without a proportionate increase in defects or waste.

These benefits are crucial for companies manufacturing products like home improvement tools, sporting goods, automotive components, or outdoor equipment, where precision, cost-effectiveness, and reliable delivery are non-negotiable.

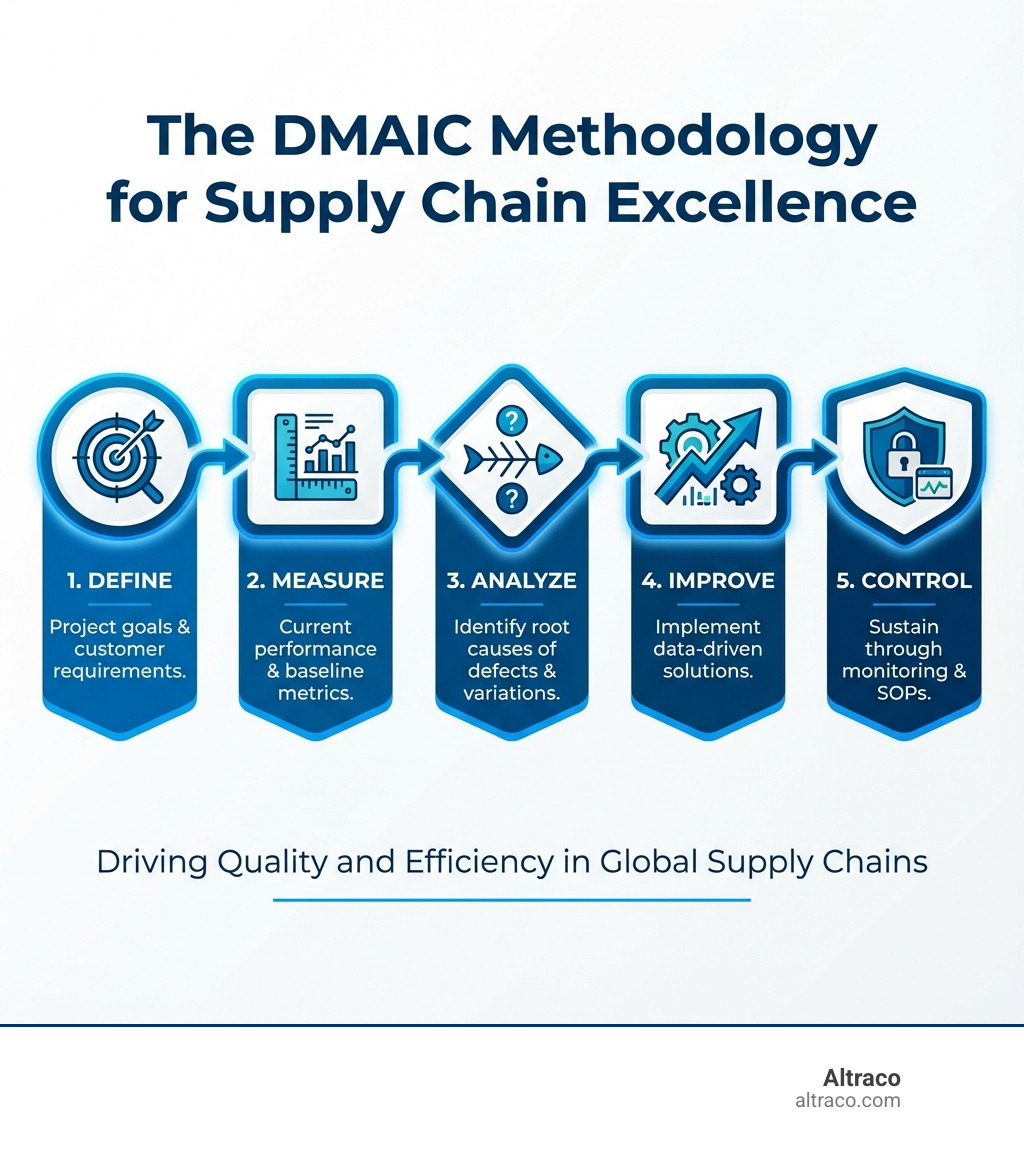

How to Apply Six Sigma: The DMAIC Methodology in Action

The cornerstone of six sigma in supply chain management is the DMAIC methodology. This systematic, data-driven approach provides a roadmap for improving existing processes that fall below specifications and need incremental improvement. It’s a powerful tool for tackling complex supply chain problems, from reducing lead times to preventing defects in overseas manufacturing operations.

Let’s consider a real-world example: A manufacturing company faced challenges with its supply chain, including high lead times, frequent stockouts, and quality issues from suppliers. Through the application of Six Sigma, lead times were reduced by 30%, stockouts were virtually eliminated, and supplier quality improved by 20%. This kind of success, particularly for automotive parts manufacturing, highlights the power of DMAIC. For more insights on ensuring quality in your manufacturing, check out our proven tips to improve quality in overseas manufacturing.

Define: Setting the Stage for Success

In the “Define” phase, we clearly articulate the problem, project goals, and scope. This is where we identify the customer requirements and expectations, understanding what “quality” truly means to them. For instance, if our client is a home improvement brand, their customer might define quality as durable, easy-to-assemble products delivered on time. We create high-level process maps to visualize the current flow and establish a project charter, outlining objectives, resources, and timelines. When we’re sourcing from Mexico or Vietnam, this phase often involves defining specific quality control parameters and delivery expectations with our factory partners.

Measure: Quantifying Your Current Performance

The “Measure” phase is all about data. We collect relevant data from our current processes to establish a baseline performance. This allows us to quantify the problem identified in the Define phase. Key Performance Indicators (KPIs) are crucial here. In supply chain management, these often include:

- Perfect Order Rate: This KPI measures the percentage of orders processed without any defects and delivered on time, complete, and with accurate documentation. It’s a holistic measure of customer satisfaction.

- Cash-to-Cash Cycle Time: This measures the time it takes for our cash to convert back into cash, from paying for raw materials to receiving payment for sold products. Streamlining this cycle improves cash flow.

- Fill Rate: This KPI evaluates how many orders can be completed instantly with the stock on hand, measuring the proportion of orders immediately satisfied with available inventory.

- Inventory Turnover: This measures how often our complete inventory is sold and replaced within a specified period, indicating efficiency in stock management.

By accurately measuring these and other relevant KPIs, we gain a clear, quantitative understanding of where our processes stand. This data is vital for identifying areas for improvement and for later measuring the impact of our changes. A comprehensive tool like a balanced scorecard for supply chain can be invaluable here.

Analyze, Improve, and Control: Driving and Sustaining Change

With robust data in hand, the “Analyze” phase focuses on identifying the root causes of variations and defects. We use statistical tools like Pareto charts, cause-and-effect diagrams (like the fishbone diagram above), and hypothesis testing to pinpoint why processes aren’t performing as expected. For example, if we’re seeing defects in sporting goods manufactured in China, we might analyze production data to uncover specific equipment issues, material inconsistencies, or training gaps.

The “Improve” phase is where we develop and implement solutions to address these root causes. This often involves brainstorming potential solutions, conducting experiments, and piloting changes on a small scale before full implementation. The goal is to eliminate waste, prevent defects, and streamline processes.

Finally, the “Control” phase is about sustaining the improvements we’ve made. We establish control mechanisms, standard operating procedures (SOPs), and monitoring systems to ensure that the process maintains its new, improved level of performance. This includes ongoing data collection and analysis to prevent regression and ensure continuous improvement. Regular quality checks and adherence to a strict quality control program are essential here. An academic approach to measuring the impact and ROI of these initiatives is also crucial, as discussed in research on the application of Six Sigma in Supply Chain Management: Evaluation and Measurement Approach.

The Role of Technology and Data in Six Sigma

In today’s , globalized supply chains, technology and data are not just helpful—they are indispensable to successful six sigma in supply chain management. They act as the central nervous system, providing the visibility and analytical power needed to drive process improvement and defect reduction.

Process digitization is a game-changer. Modern systems like Warehouse Management Systems (WMS) and Transportation Management Systems (TMS) provide real-time data on inventory levels, order fulfillment, and shipment tracking. For instance, a WMS can help an online store improve its Perfect Order Rate by accurately tracking product locations and improving order accuracy, particularly crucial for diverse product lines like outdoor equipment. A TMS can reduce Cash-to-Cash Cycle Time by tracking cash flow related to transportation and optimizing payment processes. Voice-picking systems, guiding warehouse workers, can significantly speed up product selection and improve Fill Rate.

Data analytics is the engine that converts raw information into actionable insights. Six Sigma is inherently data-driven, relying on robust data collection and analysis to identify root causes and measure improvements. Predictive forecasting, powered by advanced analytics, allows us to anticipate demand more accurately, optimizing inventory levels and preventing stockouts, which in turn improves our Inventory Turnover.

The integration of Artificial Intelligence (AI) and Machine Learning (ML) is taking Six Sigma capabilities to new heights. These technologies can process vast amounts of data to identify complex patterns, predict potential defects or delays before they occur, and even suggest optimal solutions. For example, AI can analyze historical data from our manufacturing facilities in China or Vietnam to predict equipment failure, allowing for proactive maintenance and preventing production delays. This kind of technological innovation is making Lean Six Sigma practices more accessible and powerful than ever. As Purdue University aptly puts it, you can truly improve your supply chain with Lean Six Sigma.

Building a Culture of Excellence and Overcoming Challenges

Implementing six sigma in supply chain management is not just about tools and methodologies; it’s fundamentally about people and culture. It requires a shift from a traditional, reactive mindset to one of continuous improvement and proactive problem-solving.

| Feature | Traditional Supply Chain Mindset | Six Sigma Continuous Improvement Culture |

|---|---|---|

| Approach to Problems | Reactive; fix issues as they arise | Proactive; prevent defects and variations from occurring |

| Decision Making | Intuitive, experience-based, siloed | Data-driven, fact-based, collaborative |

| Focus | Meeting daily targets, cost-cutting (often short-term) | Process optimization, quality, customer value, long-term sustainability |

| View of Waste | An unavoidable cost of doing business | An opportunity for improvement and cost reduction |

| Employee Role | Executing tasks, limited involvement in problem-solving | Empowered to identify issues, contribute solutions, continuous learning |

| Supplier Relations | Transactional, adversarial (sometimes) | Collaborative, partnership-focused, shared quality goals |

Common Challenges of Six Sigma in Supply Chain Management

While the benefits are clear, implementing Six Sigma in our supply chains, especially complex global ones, comes with its own set of problems:

- Cultural Resistance and Change Management: People are naturally resistant to change. Employees may be comfortable with existing processes, even if inefficient. Overcoming this requires strong leadership support, clear communication about the “why,” and proper training.

- Data Availability and Quality Issues: Six Sigma is data-driven, so if data is scarce, inaccurate, or inconsistent across different parts of a global supply chain (e.g., between a U.S. client and a factory in Mexico), the analysis can be flawed. Investing in robust data collection systems is crucial.

- Complexity of Extended Supply Chains: Our global supply chains, spanning multiple continents and involving numerous partners, are inherently complex. Standardizing processes and ensuring consistent data flow across this extended network can be a significant challenge.

- Resistance from Suppliers and Partners: Convincing overseas manufacturers, like those we work with in Vietnam or China, to adopt new methodologies can be tough. It requires building strong relationships, demonstrating mutual benefits, and providing support and training. This is precisely why international sourcing services are critical.

- Balancing Standardization with Flexibility: While Six Sigma promotes standardization to reduce variation, supply chains often need flexibility to respond to market changes or unforeseen disruptions. Finding the right balance is key to avoiding rigidity.

The Relevance of Six Sigma Certification in Supply Chain Management

To effectively steer these challenges and champion Six Sigma initiatives, specialized knowledge is essential. This is where Six Sigma certification comes into play. These certifications, often compared to martial arts belts, signify different levels of expertise:

- White Belt: Basic understanding of Six Sigma concepts and its language.

- Yellow Belt: Understands the basics, supports project teams, and can apply some Lean tools.

- Green Belt: Leads smaller projects, collects and analyzes data, implements solutions.

- Black Belt: Full-time expert, leads complex projects, mentors Green Belts, and applies advanced statistical analysis.

- Master Black Belt: Strategic leader, trains Black and Green Belts, drives Six Sigma deployment across the organization.

For professionals in supply chain roles, these certifications are highly relevant. They equip individuals with the skills to identify problems, analyze data, implement solutions, and drive continuous improvement, making them invaluable assets to any organization looking to optimize its global operations. Beyond individual career growth, having certified personnel within our organization ensures we have the in-house expertise to manage and improve our offshore manufacturing processes effectively.

Conclusion: Making Your Supply Chain Defect-Free

We’ve seen that six sigma in supply chain management is far more than a fleeting business trend; it’s a robust, data-driven methodology that offers profound and lasting benefits. By integrating its principles with Lean thinking, we can systematically reduce waste, prevent defects, and improve efficiency across every facet of our supply chain. The DMAIC framework provides a clear path to identify problems, measure performance, analyze root causes, implement effective solutions, and control processes to sustain improvements.

From drastically cutting operational costs and improving product quality to fostering stronger supplier relationships and boosting customer satisfaction, the impact of Six Sigma is undeniable. The strategic application of technology and data analytics further amplifies these benefits, changing our ability to manage complex global operations.

However, implementing Six Sigma is a journey, not a destination. It requires a commitment to continuous improvement and a cultural shift that accepts data-driven decision-making and proactive problem-solving. While challenges like cultural resistance and data quality exist, the rewards of a defect-free, highly efficient supply chain are well worth the effort.

For businesses manufacturing sporting goods, home improvement products, automotive parts, or outdoor equipment overseas, a partner like Altraco can be instrumental. We leverage decades of experience and trusted factory relationships in countries like China, Mexico, and Vietnam to implement these quality principles on the ground. Our expertise ensures your global operations are not only efficient and reliable but also continuously improving, delivering significant cost savings and consistently high-quality products.

Ready to transform your supply chain into a lean, defect-free powerhouse? Explore our Integrated Supply Chain Services to see how we can help.