Why Modern Manufacturers Need Barcode Inventory Systems

Barcoding inventory management software combines barcode scanning with centralized databases to automatically track products throughout your supply chain. Here’s a quick overview:

- What it is: Software that uses barcode scanners to capture and update inventory data in real-time.

- How it works: A barcode is scanned, data is sent to the central software, and inventory records update instantly.

- Key components: Barcode labels, scanning devices (handheld, mobile, or fixed), and inventory software.

- Main benefits: Eliminates manual data entry, speeds up operations, and provides real-time stock visibility.

- Types of barcodes: 1D (linear, like UPC) for basic info and 2D (QR codes, Data Matrix) for detailed data.

An estimated 10 billion barcodes are scanned every day globally. For manufacturers managing complex supply chains—especially those producing home improvement products, automotive parts, or sporting goods overseas—this technology is essential.

When coordinating contract manufacturing across Mexico, Vietnam, or China, a single data entry error can cause shipping delays or customs problems. Barcoding eliminates these risks by creating an automated, traceable record from your contract manufacturer to your customer.

Manual tracking with spreadsheets can’t keep pace. For example, one company reduced inventory shrinkage by 90% after implementing barcode scanning, while another saved significant time by eliminating picking errors.

The power of barcoding lies in what happens after the scan. That action triggers automated updates: inventory counts adjust, reorder alerts are sent, location data refreshes, and financial records update. For businesses managing tariffs and multi-country sourcing, this real-time visibility is a major competitive advantage.

I’m Albert Brenner, and in my 40+ years running a contract manufacturing company, I’ve seen barcoding inventory management software transform operations for Fortune 500 clients producing automotive and outdoor products internationally. The ability to maintain accurate, real-time inventory data is often what separates thriving companies from those that struggle with offshore manufacturing.

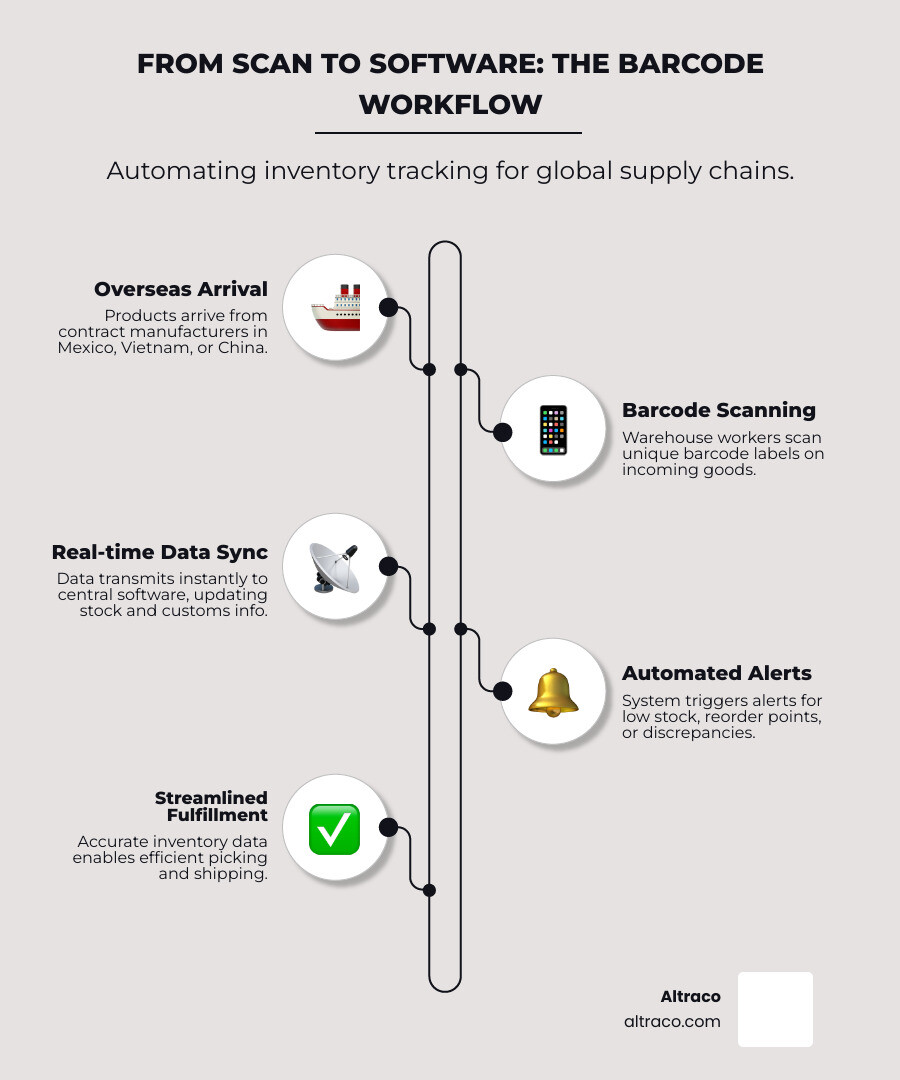

How a Barcode System Works: From Scan to Software

A barcode inventory system tracks products using unique barcodes and specialized software, creating a seamless flow of information from the physical item to your digital records. Think of a barcode as a digital passport for every item in your warehouse, from a single automotive part to a pallet of home improvement goods.

The process is simple and powerful. A barcode label is affixed to an item. A scanner reads the encoded information and instantly transmits it to a central inventory software, which processes the data and updates records in real-time. This automation is crucial for streamlining operations, especially when managing goods from international sourcing partners.

For example, when a container of sporting goods from a factory in Vietnam arrives at our Long Beach, CA, facility, a single scan logs the inventory, updates quantities, and assigns a storage location. This eliminates slow, error-prone manual data entry.

This real-time capability improves every stage of inventory management:

- Receiving: Products from contract manufacturers are scanned and registered immediately, ensuring accurate stock levels from the start.

- Picking and Packing: Warehouse teams use scanners to verify they are picking the correct items for an order, reducing errors and speeding up fulfillment.

- Cycle Counts: Instead of disruptive full-scale audits, teams can conduct targeted counts by scanning specific areas, making the process faster and more accurate.

According to GS1, the organization behind the global barcode standard, an estimated 10 billion barcodes are scanned every day, underscoring just how fundamental this technology has become to modern supply chains.

The technology behind this process involves both the scanner and the software. Scanners—whether they are simple laser scanners for 1D barcodes or more versatile camera-based imagers for 2D barcodes—translate the visual pattern into digital data. This data is then sent to the central inventory database, the “brain” of the operation.

The real power comes from integrating this data with other business systems. Barcoding inventory management software often connects with Enterprise Resource Planning (ERP) and accounting systems. This means a single scan can update inventory, trigger tariff calculations for an inbound shipment of automotive parts, and update financial records. This integration provides a unified, accurate view of the business, which is indispensable for managing a global supply chain from our offices in Thousand Oaks, CA, to the warehouse floor in Los Angeles, CA.

Decoding the Lines: 1D vs. 2D Barcodes

Not all barcodes are created equal. Understanding the difference between 1D and 2D barcodes is crucial for choosing the right barcoding inventory management software for your business, as they differ in data capacity, readability, and application.

Traditional 1D (Linear) Barcodes

These are the familiar striped barcodes (like UPCs) seen on most retail products. They store a small amount of alphanumeric data horizontally.

- Best for: Basic product identification, price lookups, and simple inventory tracking. They are ideal for high-volume scanning of home improvement materials or sporting goods at checkout.

- Common Types: UPC, EAN, Code 39, and Code 128.

- Limitations: They hold limited data and can be difficult to read if damaged.

Advanced 2D (Matrix) Barcodes

These newer, square-patterned barcodes (like QR codes) store data both horizontally and vertically, allowing them to hold significantly more information.

- Best for: Detailed asset tracking, serialization, and managing complex data like an item’s country of origin or tariff codes. For our contract manufacturing of automotive parts, 2D barcodes provide superior traceability.

- Common Types: QR Code, Data Matrix, and PDF417.

- Advantages: They have built-in error correction, meaning they can often be scanned even if damaged. They can also be read from any angle.

For simple identification, 1D barcodes suffice. But for the detailed tracking required in global sourcing and logistics, 2D barcodes are a clear winner.

[TABLE] comparing 1D vs. 2D Barcodes

| Feature | 1D (Linear) Barcodes | 2D (Matrix) Barcodes |

|---|---|---|

| Data Capacity | Limited (typically 20-25 characters) | High (hundreds to thousands of characters) |

| Read Orientation | Must be scanned horizontally | Can be scanned from any angle (omnidirectional) |

| Size | Varies with data length, can be long | Compact, efficient use of space |

| Error Correction | Minimal to none | High (can be read even if partially damaged) |

| Common Use Cases | Retail products, basic inventory, price lookup | Detailed asset tracking, serialization, batch tracking, URLs |

Key Benefits of Implementing Barcoding Inventory Management Software

Implementing barcoding inventory management software transforms manufacturing operations, turning guesswork into precision. For businesses with global supply chains, the benefits impact everything from the bottom line to customer satisfaction.

Key benefits include:

- Increased Accuracy: Barcode scanning virtually eliminates manual data entry errors, preventing inventory discrepancies, incorrect orders, and financial losses.

- Improved Efficiency: Tasks like receiving shipments, fulfilling orders, and inventory checks are dramatically accelerated, boosting overall productivity.

- Cost Savings: Reduced errors, optimized inventory levels, and lower labor costs lead to substantial savings.

- Real-Time Data Visibility: Get a live, accurate overview of your stock. When a barcode is scanned, the central database updates instantly, providing invaluable data for decisions on purchasing and production.

- Better Decision-Making: Accurate, real-time data allows for better demand forecasting, warehouse optimization, and strategic management of your global supply chain, including navigating tariffs.

- Scalability: A good system grows with your business, easily handling more inventory, locations, and product lines, which is crucial for our Fortune 500 clients.

Boosting Efficiency in Your Business Operations

Barcoding streamlines key warehouse activities. Receiving shipments of sporting goods from Mexico or fulfilling orders for home improvement products becomes faster and more accurate. By automating manual tasks and minimizing picking errors (like sending the wrong automotive part), you reduce labor costs and improve customer satisfaction. It also enables end-to-end traceability, allowing you to track components from a factory in China through every stage of distribution, which is invaluable for quality control and compliance.

Using barcoding inventory management software for Asset Tracking

Beyond inventory, this software is essential for tracking valuable company assets, such as tools, machinery, and equipment used in manufacturing. By barcoding assets, you can:

- Track Location and Usage: Know who has what tool and where it is.

- Monitor Maintenance Schedules: Scan an asset to see its service history and prevent unexpected downtime.

- Reduce Asset Loss: Implement a simple check-in/check-out process to ensure every asset is accounted for, from jigs in a factory in Vietnam to logistics equipment in Los Angeles, CA.

Choosing the Right Barcoding Inventory Management Software

Selecting the right barcoding inventory management software is a critical decision. The needs of a small business differ greatly from a multinational enterprise, so it’s important to find a solution that aligns with your operations and future growth.

Key features to consider include:

- Scalability: Can the software grow with your business?

- Integration Capabilities: Does it connect with your existing ERP, accounting, and e-commerce platforms? An open API offers maximum flexibility.

- Hardware Compatibility: Does it support your preferred scanners and label printers?

- User-Friendliness: Is the interface intuitive for your team?

- Reporting and Analytics: Does it provide actionable insights into inventory and sales trends?

- Customization: Can you add custom fields for data like tariff codes or quality control metrics?

Considerations for Small Businesses

For small businesses, the focus is on affordability, simplicity, and quick implementation.

- Look for: Cloud-based solutions with subscription pricing, an intuitive user interface, and mobile app functionality that allows you to use smartphones as scanners. This approach provides immediate benefits without a massive investment for a company managing home improvement products or outdoor gear.

Scaling Up: Needs for Large Enterprises

For large enterprises like our Fortune 500 clients, the requirements are more complex, emphasizing robust capabilities and comprehensive control.

- Look for: Advanced, bi-directional ERP integration (e.g., SAP, Oracle), multi-location support for managing inventory across global facilities, and extensive customization options. The software must also have robust security protocols and features to manage complex supply chains, such as batch tracking, serialization, and the data granularity needed to steer international tariffs and customs. An open API is vital for creating custom workflows to connect disparate systems.

Frequently Asked Questions about Barcode Inventory Systems

We often encounter common questions about barcoding inventory management software. Let’s address a few of the most frequent ones:

How does a barcode system help manage inventory from overseas contract manufacturing?

For businesses working with contract manufacturers in countries like Mexico, China, and Vietnam, a barcode system provides critical end-to-end visibility. It helps by:

- Precise Tracking: Track individual items or batches of automotive parts or outdoor gear as they move through international shipping.

- Simplifying Customs and Tariffs: Detailed data encoded in barcodes (like country of origin) is crucial for accurate customs declarations and navigating tariffs, helping avoid costly delays and fines.

- Improving Quality Control: Link barcodes to inspection data to ensure products meet standards before they ship. Batch tracking allows for quick isolation of any affected products.

- Reducing Errors: Automating data capture eliminates manual errors that lead to mislabeled shipments or customs hold-ups.

Can I use my smartphone as a barcode scanner?

Yes. Many modern barcoding inventory management software solutions offer mobile apps that turn a smartphone or tablet into a capable barcode scanner. This is a cost-effective option for small businesses or for employees who don’t need a dedicated rugged scanner. While dedicated scanners are faster for high-volume work, a smartphone is an excellent and convenient tool for many inventory tasks.

What is the difference between a 1D and 2D barcode scanner?

The main difference is the type of barcode they can read:

- 1D Barcode Scanners: These use a laser to read traditional linear (1D) barcodes, like UPCs. They are fast for simple product codes but cannot read 2D barcodes.

- 2D Barcode Scanners (Imagers): These use a camera to capture an image, allowing them to read both 1D and 2D barcodes (like QR codes) from any angle. They can also read barcodes that are damaged or displayed on a screen, making them more versatile for complex logistics.

Conclusion: Gain Control of Your Supply Chain

In today’s global economy, managing inventory effectively is no longer just about counting items; it’s about leveraging technology to gain a competitive edge. Barcoding inventory management software stands out as a foundational tool for achieving this. We’ve explored how these systems work, the critical differences between 1D and 2D barcodes, and the immense benefits they bring, from boosting efficiency and accuracy to enabling real-time data visibility and significant cost savings.

For businesses engaged in manufacturing – whether it’s home improvement products, sporting goods, automotive parts, or outdoor gear – and especially those navigating the complexities of international sourcing and contract manufacturing in locations like Mexico, China, and Vietnam, barcoding is indispensable. It transforms manual, error-prone processes into streamlined, automated workflows, providing the precise data needed to manage inventory, track assets, and confidently steer tariffs and global logistics.

The future of inventory management is intelligent, integrated, and immediate. By adopting robust barcoding inventory management software, businesses can move beyond reactive problem-solving to proactive strategic planning. This empowers us to make smarter decisions, optimize our operations, and ultimately deliver higher quality products to our customers, on time and within budget.

If you’re looking to improve your global supply chain and manufacturing processes, or need a partner who understands the intricacies of international sourcing and production, we’re here to help. Find how our expertise can benefit your business.