Understanding Value Added Value Engineering: The Key to Smarter Product Development

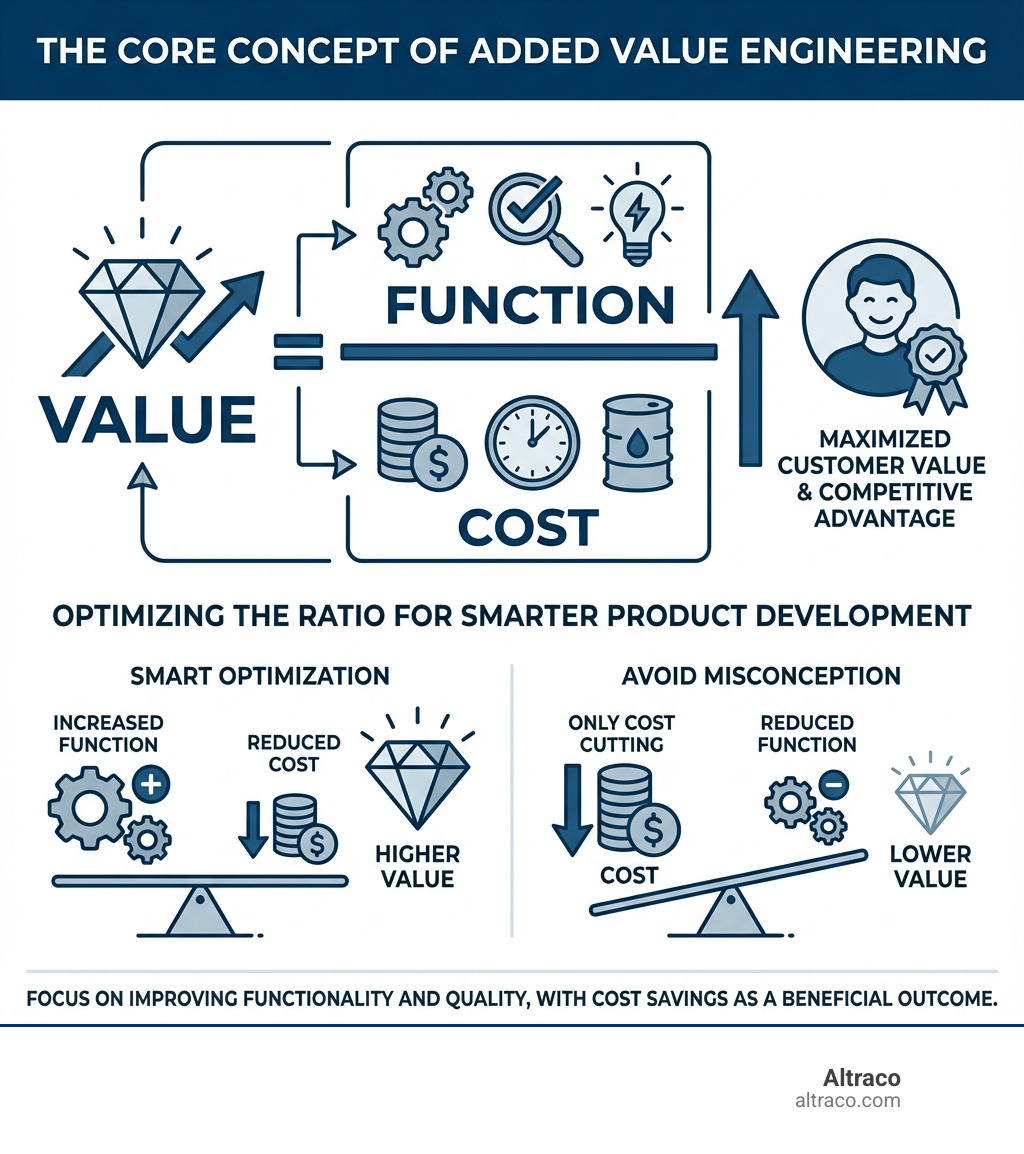

Value added value engineering is a systematic method for improving the value of products and processes by optimizing their functions while reducing unnecessary costs—without sacrificing quality or performance. At its core, VAVE helps companies make smarter decisions about product design, materials, and manufacturing processes to maximize customer value and maintain competitive advantage.

Quick Answer: What is Value Added Value Engineering?

- Definition: A structured methodology to maximize product value through the formula: Value = Function / Cost

- Primary Goal: Improve product functionality and quality while maintaining or reducing costs

- Key Phases: Information gathering, function analysis, creative brainstorming, evaluation, development, presentation, and implementation

- Main Benefits: Cost reduction (often 15-30%), improved quality, increased innovation, and better customer satisfaction

- Best Timing: Most effective during the design stage, where 70-80% of product costs are fixed

- Common Applications: Automotive parts, home improvement products, sporting goods, outdoor equipment, and industrial manufacturing

One of the common misconceptions about value added value engineering is that it focuses solely on cutting costs. In reality, the primary focus is on improving functionality and quality—cost savings are a beneficial outcome, not the only goal.

The concept originated in the 1940s at General Electric during World War II, when material shortages forced engineers to find creative alternatives that often performed as well or better than original specifications. This accidental findy evolved into a formal methodology that today helps manufacturers worldwide optimize their products and processes.

For companies navigating offshore manufacturing, especially in light of recent tariff challenges and supply chain disruptions, value added value engineering becomes even more critical. It’s not just about finding the cheapest production option—it’s about making strategic decisions that balance cost, function, and quality across global manufacturing partners in countries like Mexico, Vietnam, and China.

I’m Albert Brenner, and over 40 years of co-owning a contract manufacturing company, I’ve applied value added value engineering principles to help Fortune 500 clients optimize their products across home improvement, sporting goods, automotive parts, and outdoor equipment categories. This methodology has been fundamental to delivering quality products on time while navigating the complexities of international manufacturing and tariff challenges.

What is Value Added Value Engineering (VAVE)?

At Altraco, we understand that added value engineering (VAVE) is more than just a buzzword; it’s a strategic approach to product development and manufacturing that can significantly impact a business’s bottom line and market position. This section defines the core concepts, history, and different types of value considered in VAVE, a systematic method for improving the value of products and processes.

Defining Value in Engineering

At its heart, VAVE is a disciplined, systematic process designed to maximize a product’s worth by optimizing its functions and reducing unnecessary costs, all without sacrificing quality or performance. It’s a proactive methodology that scrutinizes every aspect of a product’s lifecycle, from initial design to final delivery, to ensure that every component and process contributes meaningfully to its overall value.

A common misconception we often encounter is that VAVE is solely about cost-cutting. While cost reduction is a significant benefit, it’s not the primary driver. Our goal with VAVE is to improve product functionality and quality. By doing so, we naturally uncover opportunities for cost savings. As the experts at Investopedia explain, value engineering is a method to improve a project’s value by optimizing functions and reducing costs, often through material or method substitutions, without sacrificing quality. This comprehensive approach ensures that the solutions we develop are responsible and have a minimal environmental impact, aligning with our commitment to sustainable practices.

A truly efficient design and process, effectively utilizing added value engineering methods, should result in a product design and assembly process that yields a world-class product at the lowest possible cost, with the greatest functionality. This is the philosophy we accept at Altraco, offering strategic and operational consulting services that generate genuine added value and increase competitiveness for our clients. For a deeper dive into this concept, you can refer to Investopedia’s guide on Understanding Value Engineering.

The Core Formula: Function vs. Cost

The fundamental principle behind VAVE is neatly captured by a simple formula:

Value (V) = Function (F) / Cost (C)

This equation illustrates that value can be increased in several ways:

- By increasing the function while keeping the cost the same.

- By reducing the cost while maintaining the same function.

- By increasing the function and simultaneously reducing the cost.

At Altraco, we carefully consider the entire product lifecycle cost, including production, design, maintenance, and replacement, when applying this formula. Value engineering aims to maximize function while minimizing cost, without sacrificing quality. It’s about finding that sweet spot where a product delivers optimal performance and features at the most efficient price point. This balance is crucial for our clients, who often seek to develop new products or refine existing ones in competitive markets.

A Brief History and the Types of Value

The concept of value engineering wasn’t born in a boardroom but out of necessity during a global crisis. It originated in the 1940s at General Electric Co during World War II. Faced with severe material shortages, engineer Lawrence D. Miles was tasked with finding alternative components and raw materials to keep production lines running. What he finded was groundbreaking: many of these substitutes not only maintained quality but often improved performance or reduced costs. This “accidental findy” laid the foundation for what would become added value engineering. You can learn more about this fascinating origin story through the History of Value Engineering at McGill University.

In VAVE, we consider four primary types of value that a product or service can possess:

- Use Value: This refers to the functional utility of a product – what it does, how it performs, and its practical purpose. For a home improvement tool, its use value might be its ability to cut, drill, or fasten efficiently.

- Cost Value: This is the monetary sum required to produce, acquire, or maintain a product. We constantly strive to optimize this through our offshore contract manufacturing, ensuring the best possible cost without compromising quality.

- Esteem Value: This is the subjective value or desirability a customer places on a product, often related to prestige, brand recognition, or aesthetic appeal. Think of a premium outdoor gear brand – its esteem value might allow it to command a higher price.

- Exchange Value: This is what a product can be traded for, its market price, or its resale value. It’s influenced by both its use and esteem value, as well as market demand.

Understanding these different facets of value allows us to approach product optimization holistically, ensuring we address both the tangible and intangible aspects that drive customer satisfaction and market success.

The VAVE Process: A Step-by-Step Guide to Implementation

Implementing added value engineering is not a haphazard endeavor; it’s a structured, systematic process guided by well-defined phases. This section outlines the structured phases, tools, and collaborative efforts involved in a successful VAVE project, from initial analysis to final implementation.

The Standard Job Plan Phases

The VAVE process, often referred to as the “Job Plan,” typically involves a series of distinct phases, ensuring a thorough and methodical approach to value improvement. At Altraco, we guide our clients through these steps, leveraging our expertise in global manufacturing.

Here’s a typical breakdown of the VAVE phases:

- Information Gathering: This initial phase involves collecting all relevant data about the product, process, or service under review. We gather comprehensive information about its purpose, usage, design specifications, manufacturing processes, and associated costs. This is where we identify potential pain points through detailed production analysis, ensuring precision in our approach.

- Function Analysis: This is the cornerstone of VAVE. We break down the product into its basic functions, defining them using a verb-noun combination (e.g., “provide light,” “secure panel”). We then assign costs to each function, allowing us to identify functions with high costs relative to their perceived value. This phase helps us understand what the product must do versus what it currently does.

- Creative Brainstorming: With a clear understanding of functions and costs, we engage in cross-functional collaboration to generate alternative ideas. This phase encourages innovative and risk-taking approaches, questioning existing methods and designs. We blend innovative technology with proven designs and lessons learned from existing product lines to breathe new life into projects.

- Evaluation: In this phase, we assess the feasibility, cost implications, and potential value addition of the generated ideas. We weigh the advantages and disadvantages of each alternative, ensuring that any proposed changes will truly improve value without compromising essential functions or quality.

- Development: The most promising ideas are then developed into viable solutions. This involves creating detailed plans, sketches, prototypes, and cost estimates. Our team, alongside our manufacturing partners in locations like Mexico and Vietnam, works to integrate new elements with existing ones, often using parts from existing products with minor modifications to maximize performance and cost-effectiveness.

- Presentation: The developed solutions and their projected benefits are presented to stakeholders and decision-makers for approval. We provide clear, objective information, including updated forecasts and visualizations, to help management make informed decisions.

- Implementation & Monitoring: Once approved, the changes are implemented. This phase also includes ongoing monitoring to ensure the optimal function of the new design or process. We track cost savings and performance improvements, making adjustments as needed.

Cross-functional collaboration is paramount throughout this process. We bring together experts from various disciplines—engineering, procurement, manufacturing, logistics—to gain diverse perspectives and ensure comprehensive solutions.

Essential Tools and Techniques for VAVE

To effectively steer the VAVE process, we employ a range of proven tools and techniques:

- Function Analysis System Technique (FAST): This diagramming tool helps us visually represent and understand the logical relationships between various functions of a product or process. It clearly distinguishes between basic and secondary functions.

- Brainstorming: A classic technique for generating a large quantity of creative ideas in a group setting. It’s crucial during the Creative Phase to explore alternative ways to achieve desired functions.

- Benchmarking: By comparing our product’s functions and costs against industry best practices or competitors, we identify areas for improvement and set realistic targets.

- Life Cycle Cost Analysis (LCCA): This tool evaluates the total cost of a product over its entire lifespan, including initial acquisition, operation, maintenance, and disposal. This ensures we don’t just optimize for upfront costs but for long-term value.

- Design for Manufacturability (DFM): We integrate DFM principles early in the design phase to ensure products are designed for cost-effective and efficient manufacturing. This is particularly relevant in our offshore contract manufacturing operations.

- Design for Assembly (DFA): Optimizing product design for efficient and easy assembly helps reduce labor content and assembly time, which are significant cost drivers.

- Pareto Analysis: Also known as the “80/20 rule,” this helps us identify the few critical functions or components that contribute to the majority of costs or problems, allowing us to prioritize our VAVE efforts.

- Value Stream Mapping (VSM): A lean manufacturing tool that visualizes the flow of materials and information required to bring a product to the customer. It helps identify non-value-added activities and waste.

- Function-Cost Matrix: This matrix helps us correlate specific functions with their associated costs, highlighting areas where the cost-to-function ratio is disproportionately high.

Our expertise in contract manufacturing services and quality control aligns perfectly with these tools, ensuring robust product development and strong supplier relationships.

Overcoming Common Implementation Challenges

While the benefits of VAVE are clear, its implementation isn’t without its problems. We’ve learned to anticipate and overcome several common challenges:

- Resistance to Change: People often prefer the status quo. We address this by involving team members early, clearly communicating the benefits, and fostering a culture that accepts innovation and continuous improvement.

- Resource Allocation: VAVE requires dedicated time, personnel, and sometimes external expertise. Securing adequate resources is crucial, and we emphasize that this is an investment, not an expense.

- Project Complexity: Modern products, especially in automotive parts or home improvement, can be incredibly complex. VAVE breaks down this complexity into manageable segments, allowing for focused analysis.

- Initial Time Investment: The information gathering and function analysis phases can be time-intensive. However, this upfront investment pays dividends by preventing costly issues later in the product lifecycle.

- Risk of Over-Engineering: Sometimes, the drive for perfection can lead to solutions that are too complex or costly for the value they provide. We balance innovation with practicality, ensuring solutions are optimal, not just elaborate.

To mitigate these challenges, we often advocate for a formal approach, such as that outlined in the Value Methodology Standard from SAVE International. This standard provides a consistent framework, helping us ensure that our VAVE efforts are systematic, thorough, and ultimately successful. By identifying pain points through production analysis and leveraging lessons learned from our extensive experience, we can make rapid adjustments with minimal investment, avoiding the trap of pushing through project issues that lead to inferior products or delays.

Core Principles and Benefits of Added Value Engineering

At Altraco, we believe that understanding the core principles that drive added value engineering is essential for open uping its full potential. These principles guide our approach, ensuring that our VAVE initiatives yield maximum impact and deliver significant benefits to our clients.

Guiding Principles for Maximum Impact

Effective VAVE isn’t just a series of steps; it’s a mindset rooted in several key principles:

- Function-Based Focus: Our primary focus is always on the essential functions a product must perform. We ask, “What does it do?” rather than “What is it?” This prevents us from getting bogged down in existing designs and opens the door to truly innovative solutions.

- Cost-Worth Analysis: We carefully evaluate whether the cost incurred for each function is justified by its worth to the customer. This helps us balance functionality and price, ensuring that every dollar spent adds tangible value. We strive to eliminate non-value-added costs for operations like tapping, inspection, and rework, which are often overlooked but significantly impact overall cost.

- Cross-Functional Teamwork: VAVE thrives on diverse perspectives. Our teams, often comprising engineers, designers, manufacturing specialists, and procurement experts, collaborate closely. This multidisciplinary approach allows us to consider all angles—from material selection to shipping logistics—and generate more robust solutions.

- Lifecycle Perspective: We consider the product’s entire life cycle, from conception and design through manufacturing, use, service, and eventual disposal. This holistic view helps us identify opportunities for value improvement at every stage, ensuring long-term sustainability and cost-effectiveness. For instance, in home improvement products, a slight design change can significantly reduce packaging waste.

- Client-Centric Approach: Value is defined by the customer. Our VAVE efforts are always geared towards meeting and exceeding client expectations, ensuring the final product delivers maximum utility and satisfaction. We ensure continuous communication and feedback throughout the process.

The Tangible Benefits of added value engineering

Implementing VAVE consistently yields impressive results for our clients across various industries, including automotive parts, sporting goods, and outdoor equipment. The benefits are far-reaching and contribute directly to business success:

- Significant Cost Reduction: VAVE can significantly reduce production costs by eliminating non-essential functions, finding cost-effective alternatives, and optimizing processes. We’ve seen projects achieve substantial savings, making them more competitive in the market. It is estimated that 70-80% of the overall cost of a product is fixed at the design stage, making this the most effective time for VAVE to impact cost.

- Improved Product Quality: By systematically analyzing components and processes, VAVE often leads to the selection of better materials, more robust designs, or more efficient manufacturing methods, directly enhancing product quality and reliability.

- Fostering Innovation: The creative phase of VAVE encourages out-of-the-box thinking, leading to novel solutions and unique product features that can differentiate our clients’ offerings in the marketplace. By focusing on innovative techniques and lower-cost alternatives, value engineering helps businesses optimize resources, improve efficiency, and maintain a competitive edge.

- Improved Customer Satisfaction: Products that offer better functionality, higher quality, and competitive pricing naturally lead to greater customer satisfaction and loyalty.

- Increased Competitiveness: All these benefits combined—cost efficiency, quality, and innovation—translate into a stronger competitive position, allowing our clients to capture market share and achieve sustainable growth.

Choosing the right manufacturing partner is critical to realizing these benefits. Our role at Altraco is to be that partner, leveraging our expertise to ensure your products benefit from the full spectrum of VAVE advantages. Learn more about Why Choosing the Right Manufacturing Partner is Critical to Your Business Success.

Real-World Applications for added value engineering

Added value engineering is a versatile methodology applicable across a wide array of industries. Our experience at Altraco has primarily focused on:

- Automotive Parts: From optimizing material choices for interior components to streamlining assembly processes for powertrain parts, VAVE ensures components are durable, cost-effective, and perform reliably under demanding conditions.

- Sporting Goods: Whether it’s redesigning a bicycle frame for lighter weight and greater strength or finding alternative materials for athletic equipment, VAVE improves performance and appeal for athletes and enthusiasts.

- Home Improvement Products: We apply VAVE to everything from power tools to plumbing fixtures, seeking to improve ease of installation, durability, and aesthetic appeal while managing manufacturing costs.

- Outdoor Equipment: For products like camping gear, garden tools, or recreational equipment, VAVE helps balance ruggedness, portability, and functionality with competitive pricing.

Beyond our core focus, VAVE is also widely applied in sectors like aerospace, construction, electronics, and medical devices. For instance, value engineering has been instrumental in large-scale infrastructure projects. The Value Engineering Applications in Transportation report highlights its use in highway projects, where systematic reviews improve performance, quality, and life-cycle costs. A famous historical example is the Golden Gate Bridge, where early value engineering efforts significantly reduced its final cost from an original budget of $100 million to approximately $35 million by substituting materials and simplifying design.

Frequently Asked Questions about Value Engineering

At Altraco, we frequently encounter questions from clients seeking to understand the nuances of added value engineering and how it can best serve their manufacturing needs. This section answers common questions to clarify the methodology and its practical application.

What’s the difference between Value Engineering and Value Analysis?

While often used interchangeably, there’s a subtle but important distinction between Value Engineering (VE) and Value Analysis (VA):

- Value Engineering (VE) is typically applied during the design or pre-production phase of a product or process. It’s a proactive approach aimed at preventing value loss by optimizing functions and costs before anything is manufactured. For example, when we work with a client on a new automotive part, we apply VE to select the best materials and design for manufacturability from the outset.

- Value Analysis (VA), on the other hand, is applied to existing products or processes that are already in production. It’s a reactive approach aimed at improving the value of something that already exists. For instance, if a client’s existing home improvement product is experiencing high manufacturing costs or customer complaints, we’d apply VA to analyze its current state and identify areas for improvement.

Both methodologies share the common goal of improving the Function/Cost ratio and use similar tools and techniques. The key difference lies in their timing: VE is about “doing things right the first time,” while VA is about “making existing things better.”

When is the best time to apply VAVE?

The most effective time to apply added value engineering is during the design stage of a product or project. Why? Because, as statistics show, an estimated 70-80% of the overall cost of a product is fixed at the design stage. This is when decisions about materials, components, manufacturing processes, and logistics are made, profoundly impacting future costs and functionality. Making changes during this phase is far less expensive and disruptive than making them once production has begun.

However, VAVE can be applied at any stage of a product’s lifecycle. While the greatest benefits are reaped early on, we can still achieve significant improvements by applying VAVE to existing products or processes. This might involve refining an existing outdoor equipment line to reduce material waste or optimizing the supply chain for sporting goods to steer tariff complexities. The earlier we engage, the more impactful our VAVE efforts can be, but it’s never too late to seek value improvement.

Is VAVE just about making things cheaper?

This is perhaps the most common misconception about added value engineering, and it’s one we’re keen to clarify. The answer is a resounding “no.” While cost reduction is a frequent and highly desirable outcome of VAVE, it is not the sole or primary goal.

The true objective of VAVE is to improve the overall value of a product or process. This means enhancing its functionality, improving its quality, and ensuring it meets or exceeds customer expectations, all while optimizing costs. Sometimes, VAVE might even recommend a slightly more expensive component if it significantly improves reliability, extends product life, or improves a critical function, increasing the overall value.

Our focus is on balancing cost and function, ensuring that any cost savings do not come at the expense of quality or essential performance. We aim for a product design and assembly process that produces a world-class product at the lowest possible cost, with the greatest functionality. This approach benefits our clients by delivering superior products that are both competitive and profitable.

Conclusion: Fostering a Culture of Continuous Value Improvement

Adopting added value engineering as a core philosophy transforms organizations, driving efficiency, fostering innovation, and cementing a competitive edge. At Altraco, we’ve witnessed how this systematic approach enables businesses to make smarter decisions, optimize resources, and deliver exceptional products to their customers. It’s about cultivating a mindset of continuous improvement, where every aspect of product development and manufacturing is scrutinized for opportunities to improve value.

Your Partner in Global Manufacturing

Fostering a VAVE culture requires strong leadership support, cross-functional collaboration, and a commitment to ongoing refinement. When integrated into the organizational DNA, VAVE becomes a powerful strategic advantage, allowing companies to respond agilely to market demands and economic shifts, such as tariff changes or supply chain disruptions.

This is where Altraco steps in as your trusted partner. With decades of experience in offshore contract and private label manufacturing, we simplify global supply chains for our clients, from Fortune 500 companies to emerging brands. Based in California, with extensive networks in key manufacturing hubs like Mexico, Vietnam, and China, we specialize in delivering quality, on-time products across the home improvement, sporting goods, automotive parts, and outdoor equipment sectors.

Our expertise extends beyond just finding factories; we steer complex tariff landscapes, leveraging our deep understanding of international trade to secure significant cost savings for our clients. By applying VAVE principles, we ensure that your products are not only manufactured efficiently but are also optimized for value, quality, and market competitiveness. We’re capable of establishing relationships in other countries as well, always seeking the best solutions for your specific needs.

Whether you’re looking to launch a new product, reduce costs on an existing line, or streamline your global manufacturing operations, our team is equipped to provide the strategic and operational consulting services that generate genuine added value.

Ready to open up the full potential of your products through added value engineering? Explore our Manufacturing Services and find how Altraco can be your strategic partner in global manufacturing.