Why Private Label Wholesalers Are Essential for Manufacturing Success

Private label wholesalers are manufacturing partners who produce products exclusively for your company to sell under your own brand name. These specialized suppliers handle everything from product development to packaging, allowing you to focus on marketing and sales while maintaining complete control over your brand identity.

Key Benefits of Private Label Wholesalers:

- Higher profit margins – Eliminate middlemen and control pricing

- Brand control – Customize products to match your specifications

- Market exclusivity – Create unique products competitors can’t replicate

- Faster market entry – Launch products without building manufacturing facilities

- Quality assurance – Work directly with producers to maintain standards

The private label market is experiencing remarkable growth, with global sales reaching $1 trillion and projected to grow at 10.8% CAGR through 2032. In the United States alone, private label products account for 17% of total retail sales, while European markets like the UK and Netherlands see private label market shares exceeding 30%.

For Fortune 500 companies manufacturing home improvement tools, sporting goods equipment, automotive parts, and outdoor products, finding the right private label wholesalers can mean the difference between struggling with complex supply chains and achieving significant cost savings with reliable quality control.

I’m Al Brenner, co-owner of a contract manufacturing company with over 40 years of experience helping Fortune 500 companies steer private label wholesalers across Mexico, China, Vietnam, and other key manufacturing regions. Through Altraco, I’ve seen how the right manufacturing partnerships can transform businesses by simplifying global supply chains and delivering quality products on time at compelling prices.

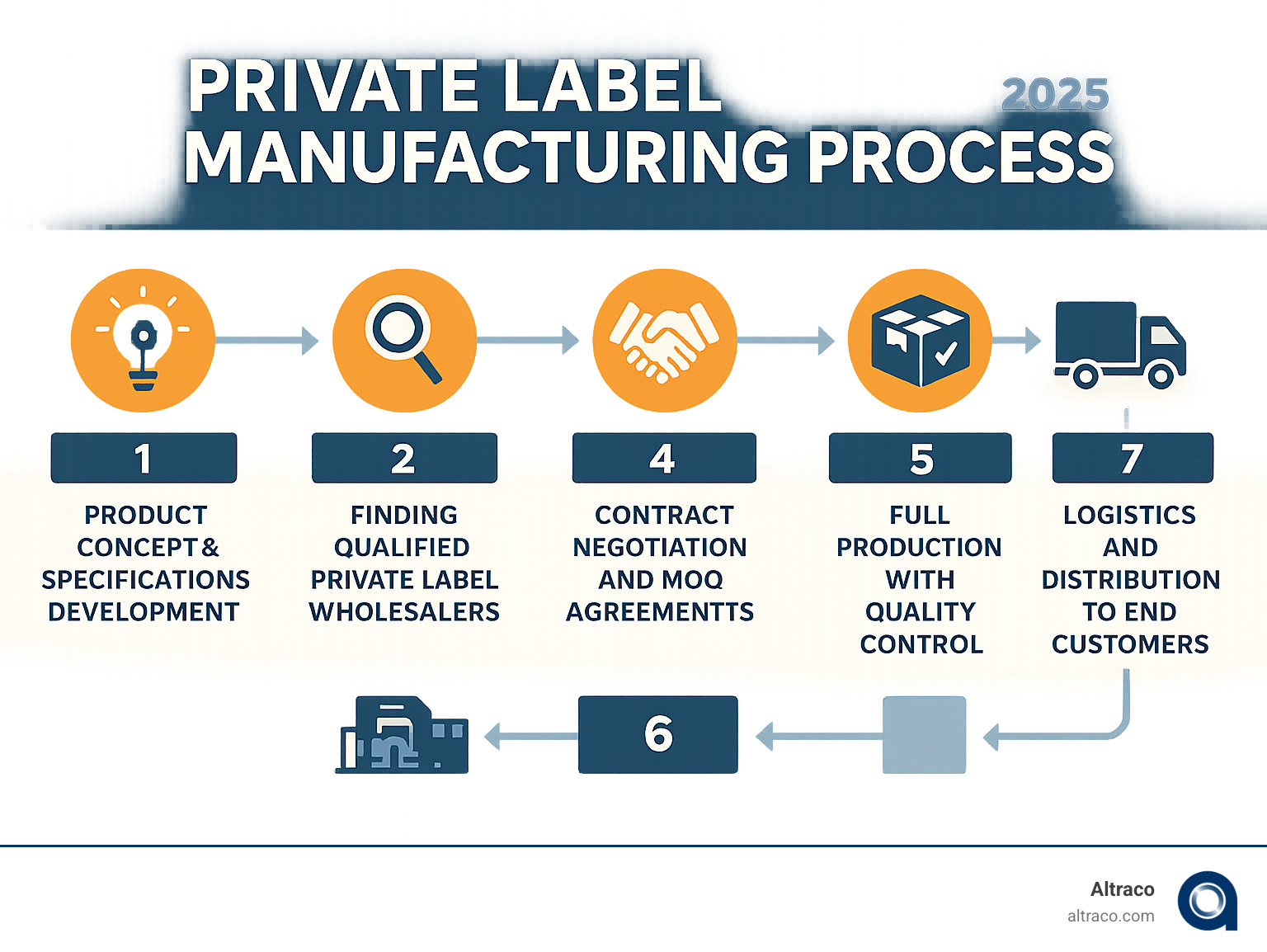

7 Smart Ways to Find the Right Private Label Wholesalers

Finding the perfect private label wholesalers isn’t like ordering takeout—you can’t just scroll through reviews and hope for the best. It requires a thoughtful strategy that goes beyond a quick Google search. You’re looking for more than just someone who can make your product; you need a reliable partner who gets your vision, maintains your quality standards, and can grow alongside your business.

This becomes even more critical when you’re exploring offshore manufacturing. The stakes are higher, the relationships more complex, and the due diligence absolutely essential. But here’s the thing—when done right, these partnerships can transform your entire business model.

At Altraco, we’ve spent over 40 years perfecting the art of finding and nurturing manufacturing relationships in Mexico, China, Vietnam, and beyond. We’ve learned that successful sourcing for home improvement tools, sporting goods, automotive parts, and outdoor products requires more than luck—it demands strategy, patience, and sometimes a little detective work.

1. Leverage B2B Sourcing Platforms and Directories

Think of B2B sourcing platforms as the dating apps of the manufacturing world—except instead of swiping right, you’re filtering by production capacity and ISO certifications. These digital marketplaces have revolutionized how businesses connect with private label wholesalers worldwide.

Alibaba remains the giant in this space, connecting businesses with manufacturers across virtually every product category imaginable. You can search specifically for “automotive parts private label manufacturer” or “outdoor gear private label supplier” and filter results by location, minimum order quantities, and even trade assurance programs.

For domestic sourcing, particularly in the US, ThomasNet.com offers a more curated approach. It’s free to use and focuses on North American suppliers, making it invaluable when you want to keep production closer to home. Meanwhile, Wonnda has carved out a niche connecting businesses with pre-vetted European manufacturers.

The key to success on these platforms isn’t just finding suppliers—it’s knowing how to evaluate them. Look beyond flashy product photos and dig into supplier profiles. Check their transaction history, read reviews from other buyers, and pay attention to response times. A manufacturer who takes three days to respond to your initial inquiry probably isn’t going to be much faster during production crises.

2. Attend Industry-Specific Trade Shows

There’s something magical about trade shows that no amount of video calls can replicate. Walking the floor of a major home improvement expo or sporting goods convention gives you superpowers—you can touch materials, assess build quality, and read body language during negotiations.

These events are goldmines for finding private label wholesalers you’d never find online. Manufacturers invest heavily in trade show participation, often bringing their best samples and most experienced sales teams. You’ll get to discuss your vision face-to-face, understand their production processes, and gauge whether you can work together long-term.

The conversations you have at these shows often reveal more than months of email exchanges. You’ll learn about their customization capabilities, get realistic timelines for production, and sometimes find they have capabilities they don’t advertise online. Plus, nothing beats the confidence that comes from seeing and feeling your potential products in person.

Trade shows also provide unexpected networking opportunities. That conversation with a competitor at the coffee stand might lead to a supplier referral, or a casual chat with another attendee could reveal industry insights that reshape your sourcing strategy.

3. Use Professional Networks and Referrals

Your professional network is like having a team of scouts working on your behalf. The best manufacturing partnerships often come from trusted referrals—someone who’s already steerd the challenges you’re facing and lived to tell about it.

LinkedIn groups focused on manufacturing and supply chain management are particularly valuable. Join groups related to your specific industry, whether that’s “Automotive Aftermarket Professionals” or “Outdoor Industry Manufacturing.” These communities are surprisingly generous with advice and recommendations when you ask thoughtful questions.

Industry forums and online communities offer another layer of insight. Business owners are often willing to share their sourcing experiences, including both success stories and cautionary tales. These candid discussions can save you from costly mistakes and point you toward reliable partners.

Direct referrals remain the gold standard. When a trusted colleague recommends a manufacturer they’ve worked with successfully, you’re getting more than just a contact—you’re getting a head start on the relationship-building process. At Altraco, many of our best factory relationships began with referrals from existing partners or clients who saw synergies between different projects.

4. Conduct Targeted Online Searches

Generic searches like “private label manufacturer” will bury you in irrelevant results. The secret is getting laser-focused with your keywords. Instead of casting a wide net, use specific combinations that reflect exactly what you need.

Try searches like “sporting goods private label manufacturer Vietnam” or “automotive parts contract manufacturing Mexico.” These targeted phrases help you find manufacturers who specialize in your product category and preferred geographic region. Don’t stop at page one of search results—many excellent manufacturers focus their marketing efforts on relationships rather than SEO.

Look for company websites that demonstrate real manufacturing expertise. The best private label wholesalers will showcase their production facilities, quality control processes, and client testimonials. Pay attention to how they present themselves—professional communication in their marketing materials often translates to professional communication throughout your partnership.

This approach is particularly effective for finding manufacturers in emerging regions or those who specialize in niche product categories. Sometimes the perfect partner is on page three of search results, waiting for someone who cares enough to look deeper.

5. Analyze Industry Supply Chains

Playing detective with industry supply chains can uncover hidden gems among private label wholesalers. This approach involves studying publicly available import/export data, trade publications, and industry reports to identify successful manufacturing relationships.

Import/export databases can reveal which factories are producing goods for established brands in your industry. If a manufacturer is already producing high-quality automotive parts for a major retailer, there’s a good chance they could handle your private label project too.

Industry publications often feature case studies or news articles about manufacturing partnerships. These stories provide insights into which suppliers are expanding, investing in new capabilities, or earning quality certifications. Trade magazines for home improvement, sporting goods, and automotive industries regularly feature supplier spotlights that can introduce you to potential partners.

This research approach helps you understand industry standards and identify manufacturers who are already meeting the benchmarks you’ll need. It’s like getting a sneak peek at the report cards of potential partners before you start conversations.

6. Partner with a Sourcing Agent or Firm

Sometimes the smartest move is admitting you need help. Partnering with an experienced sourcing firm can accelerate your search while reducing risks—especially when venturing into offshore manufacturing for the first time.

Professional sourcing partners bring on-the-ground expertise that’s impossible to replicate from your office. They understand local business cultures, speak the language (literally and figuratively), and have established relationships that took years to develop. When you need to evaluate a factory in Vietnam or negotiate terms in Mexico, having local expertise is invaluable.

The negotiation power that comes with volume and experience can translate to better pricing and more favorable terms than you might achieve independently. Experienced sourcing firms also bring sophisticated quality control management capabilities, including factory audits, production oversight, and third-party inspection services.

At Altraco, our decades of experience in offshore manufacturing have taught us that successful partnerships require more than just finding suppliers—they require ongoing relationship management, cultural bridge-building, and proactive problem-solving. Our Contract Manufacturing Services are designed to simplify these complexities, allowing you to focus on growing your business while we handle the intricacies of global production.

7. Explore Government and Trade Organization Resources

Government agencies and trade organizations offer surprisingly valuable resources for finding private label wholesalers—and they’re often underused by businesses focused on private platforms and networking.

Chambers of Commerce maintain extensive databases of member companies and can often facilitate introductions to manufacturers in specific regions. Many chambers have international programs specifically designed to support cross-border business development.

Trade associations in your industry are goldmines of information and connections. Whether you’re sourcing outdoor products or automotive parts, relevant trade associations maintain member directories and often host networking events where you can meet potential suppliers.

Embassy commercial services deserve special mention for their role in international sourcing. The commercial attachés at embassies in manufacturing hubs like Mexico, China, and Vietnam are dedicated to promoting trade relationships. They can provide market insights, help verify supplier credentials, and sometimes facilitate introductions to vetted manufacturers.

These resources add a layer of credibility and support to your sourcing efforts. When you’re evaluating potential partners in unfamiliar markets, having access to official resources can provide peace of mind and valuable market intelligence that informs your decisions.

Evaluating Your Options: What to Look for in a Partner

Once you’ve compiled your list of potential private label wholesalers, the real work begins. Finding manufacturers who can make your product is just the starting point. What you’re really after is a partner who’ll grow with your business, understand your vision, and deliver consistently over the years.

I’ve seen too many businesses get burned by choosing based on price alone. A few dollars saved per unit means nothing if your products arrive late, don’t meet specs, or worse, create quality issues that damage your brand reputation. This is especially true for complex products like automotive parts or precision sporting goods equipment.

Key Factors for Evaluating Private Label Wholesalers

The evaluation process requires looking at several critical areas that will determine whether this partnership will succeed long-term.

Minimum Order Quantities (MOQs) often become the first reality check. A manufacturer specializing in outdoor camping gear might require 1,000 units for a custom sleeping bag, while automotive brake components could demand 5,000 units due to tooling costs. The key is finding manufacturers whose MOQs match your business model and cash flow capabilities. Some experienced manufacturers offer flexibility for growing businesses, especially when they see potential for long-term volume.

Pricing structure transparency separates professional manufacturers from the rest. Quality partners provide detailed breakdowns covering unit costs, tooling expenses, custom packaging, and shipping. Be cautious of quotes that seem unrealistically low – hidden costs have a way of surfacing later. At Altraco, we ensure our clients understand every cost component upfront, so there are no surprises down the road.

Quality control processes represent your brand’s reputation in the marketplace. Look for manufacturers with established quality management systems, preferably ISO certified facilities. Ask specific questions about their testing procedures, defect handling protocols, and willingness to allow third-party inspections. For offshore manufacturing in countries like Mexico, China, and Vietnam, factory audits become even more critical.

Customization capabilities determine whether you’ll get exactly what your customers need. Can they modify materials, adjust designs, or incorporate specific features? For specialized home improvement tools or unique sporting goods equipment, this flexibility often makes the difference between a good product and a great one.

Production capacity planning prevents future headaches. A manufacturer that’s perfect for your current 2,000-unit orders might struggle when you need 10,000 units. Understanding their equipment, staffing, and expansion capabilities helps ensure they can scale with your success.

Tariff navigation expertise has become increasingly important for offshore manufacturing. The right partner understands international trade regulations and can structure shipments to minimize duties and avoid delays. This expertise can save thousands of dollars on larger orders while preventing costly shipping interruptions.

Communication skills matter more than many businesses realize. Clear, timely communication becomes crucial when coordinating production schedules, managing changes, or resolving issues. Language barriers and time zone differences can complicate offshore relationships, making responsive communication even more valuable.

The Importance of Legal and Logistical Expertise

The legal and logistical aspects of working with private label wholesalers can make or break your manufacturing relationship. These details might seem boring compared to product development, but they protect your business and ensure smooth operations.

Supplier agreements need to cover everything from product specifications to dispute resolution. A comprehensive contract eliminates confusion later and provides recourse if problems arise. Include detailed quality standards, delivery schedules, payment terms, and clear procedures for handling defects or delays. Legal review is always worthwhile, especially for international agreements.

Intellectual property protection becomes critical when sharing designs, specifications, or proprietary information. Confidentiality agreements and clear IP ownership terms prevent your innovations from becoming your competitors’ products. This protection is particularly important when developing unique outdoor products or specialized automotive components.

Product liability considerations affect both your insurance costs and legal exposure. Understanding who bears responsibility for product defects, safety issues, or regulatory compliance problems helps you make informed risk management decisions. Quality manufacturers typically carry appropriate insurance and maintain clear liability frameworks.

Regulatory compliance requirements vary by product category and target markets. Automotive parts must meet strict safety standards, while sporting goods equipment often requires specific performance certifications. Your manufacturing partner should understand these requirements and maintain compliance documentation.

Shipping and logistics coordination affects everything from inventory planning to customer satisfaction. Clarify shipping terms, lead times, customs procedures, and who handles various aspects of international transportation. Experienced partners often have established logistics networks that streamline the entire process.

At Altraco, we handle these complexities as part of our comprehensive manufacturing partnership approach. Our decades of experience with offshore production in Mexico, China, Vietnam, and other key regions means we understand both the opportunities and pitfalls. We’ve built systems and relationships that protect our clients while delivering the quality products they need to succeed in competitive markets.

The Strategic Advantages of a Private Label Model

When you partner with the right private label wholesalers, you’re not just finding a way to manufacture products—you’re open uping a powerful business strategy that can transform your entire approach to the market. This is especially true for businesses in competitive industries like home improvement, sporting goods, automotive parts, and outdoor products, where differentiation and profit margins can make or break your success.

The numbers tell a compelling story. Companies that accept private labeling typically see profit margins increase by 20-40% compared to reselling national brands. Instead of competing solely on price with identical products, you’re creating something uniquely yours.

Private Label vs. White Label: What’s the Difference?

Before diving deeper into the strategic advantages, it’s crucial to understand the distinction between private label and white label manufacturing. Many business owners use these terms interchangeably, but choosing the right approach can significantly impact your brand’s future.

| Feature | Private Label | White Label |

|---|---|---|

| Exclusivity | Exclusive to your brand; manufactured specifically for you. | Generic product, manufactured for multiple brands. |

| Customization | High degree of customization possible (design, formulation, materials). | Minimal customization (primarily branding, packaging). |

| Differentiation | Creates unique products that differentiate your brand. | Rebrands existing generic products; differentiation comes from marketing. |

| Product Design | You control product specifications and design. | Manufacturer controls product design; you apply your brand to their product. |

| Market Entry | Slower, more involved process; higher initial investment. | Faster, lower initial investment; quicker market entry. |

| Profit Margins | Generally higher due to exclusivity and control. | Can be good, but potentially lower due to lack of exclusivity. |

| Example | Your branded line of specialized outdoor camping gear with unique features. | A generic, unbranded automotive cleaning spray that you put your label on. |

Think of it this way: white labeling is like putting your name on someone else’s recipe, while private labeling lets you create your own signature dish. For businesses serious about brand building and market agility, private label manufacturing offers far more strategic value.

When we work with clients at Altraco, we often see them start with white label products to test the waters, then transition to full private label manufacturing as they grow. Our expertise in countries like Mexico, China, and Vietnam gives us the flexibility to support both approaches, but the real magic happens when companies commit to true private label partnerships.

Understanding the Role of Private Label Wholesalers in Brand Building

Private label wholesalers aren’t just suppliers—they’re your brand-building partners. The relationship goes far beyond simply manufacturing products to your specifications. They become an extension of your team, helping you create something that customers can’t find anywhere else.

Unique products are the foundation of lasting success. When you work with skilled manufacturers in regions like Vietnam for sporting goods or Mexico for automotive parts, you’re not just getting cost savings. You’re accessing specialized expertise that can help you develop products with features, materials, and quality levels that set you apart from competitors.

Customer loyalty naturally follows when people associate your brand with quality and innovation they can’t find elsewhere. We’ve seen clients develop devoted followings simply because their products solve problems in ways that mass-market alternatives don’t. That’s the power of controlling the brand message from the ground up.

The ability to respond to market trends quickly gives you a competitive edge that’s hard to match. While competitors are locked into purchasing decisions made months in advance, you can pivot, innovate, and adapt based on real-time customer feedback. This market agility becomes even more valuable as consumer preferences shift faster than ever.

Perhaps most importantly, private labeling allows you to create a product ecosystem. Instead of selling random products from different suppliers, you can build a comprehensive range under your brand. Imagine offering a complete line of home improvement tools that work together seamlessly, or outdoor gear that shares the same quality standards and design philosophy.

The private label market’s explosive growth—projected to reach over $2 trillion by 2032—reflects a fundamental shift in how consumers shop. They’re no longer automatically reaching for big-name brands. Instead, they’re seeking value, quality, and products that meet their specific needs. This trend creates an unprecedented opportunity for businesses willing to invest in the right manufacturing partnerships.

At Altraco, we’ve helped Fortune 500 companies and growing businesses alike harness these advantages through our global manufacturing network. Our decades of experience navigating international supply chains means you can focus on what you do best—building your brand and serving your customers—while we handle the complexities of offshore manufacturing.

Frequently Asked Questions about Private Label Sourcing

When businesses first explore private labeling, they often have similar concerns and questions. Having worked with countless companies over the past four decades, I’ve heard these questions repeatedly. Let me address the most common ones to help you make informed decisions about your private label wholesalers and manufacturing strategy.

What types of products are best for private labeling?

The beauty of private labeling is that it works for almost any product, but some categories offer exceptional opportunities for differentiation and profit. At Altraco, we’ve seen remarkable success with products where quality, customization, and innovation make a real difference to end users.

Home improvement tools are fantastic candidates because contractors and DIY enthusiasts value reliability and specific features. Think specialized power tools with unique attachments, ergonomic hand tools designed for specific tasks, or smart home devices that integrate seamlessly with existing systems. When you control the manufacturing process, you can build tools that truly solve problems.

Sporting goods equipment thrives in the private label space because athletes and enthusiasts are always seeking performance advantages. Custom-designed training equipment, protective gear with improved safety features, or specialized accessories for niche sports can command premium pricing. The outdoor sports market particularly rewards innovation and durability.

Automotive accessories represent a goldmine for private labeling. Car enthusiasts are passionate about quality aftermarket parts, custom interior accessories, and specialized diagnostic tools. Since compatibility and performance are critical, having direct control over manufacturing ensures your products meet exact specifications.

Outdoor and camping gear customers prioritize reliability when their safety depends on their equipment. Whether it’s innovative tent designs, ultra-durable backpacks, or specialized cooking systems, this category rewards thoughtful engineering and quality construction.

The key is choosing products where you can offer genuine improvements over existing options – better materials, smarter designs, or features that address real customer pain points.

How much does it cost to start a private label brand?

This is often the first question potential clients ask, and honestly, the answer depends on several factors. However, I always tell businesses to budget at least $1,000 to $2,000 as a realistic starting point, though many successful ventures require more.

Your biggest expense will likely be meeting the manufacturer’s minimum order quantities. For example, if you’re developing a specialized automotive tool with an MOQ of 1,000 units at $8 each, that’s $8,000 just for the initial production run. Sporting goods accessories might have lower MOQs – perhaps 500 units at $3 each – bringing your product cost to $1,500.

Beyond the product itself, you’ll need to budget for sample costs (usually $100-500), branding expenses like logo design and packaging ($500-2,000), and shipping costs to get your products from the factory to your location. If you’re working with overseas manufacturers, factor in customs duties and potential storage costs.

More complex products naturally require higher investments. A sophisticated home improvement tool with custom electronics might need $10,000-20,000 to get started, while a simple outdoor accessory could launch with just a few thousand dollars.

The good news is that working with an experienced partner like Altraco can help optimize these costs through our established factory relationships and volume purchasing power.

How do I ensure product quality with an overseas private label wholesaler?

Quality control with overseas private label wholesalers requires diligence, but it’s absolutely achievable with the right approach. After decades of managing international manufacturing relationships, I’ve learned that success comes from clear communication, thorough processes, and consistent oversight.

Start with crystal-clear product specifications. Don’t assume anything is obvious. Provide detailed technical drawings, material specifications, performance standards, and even photos of acceptable versus unacceptable finishes. For automotive parts, include exact tolerances and safety requirements. For sporting goods, specify durability testing standards.

Factory audits are non-negotiable before committing to any manufacturer. We personally visit facilities to assess their equipment, quality systems, and management practices. This reveals whether they have the capability and commitment to meet your standards consistently.

Third-party inspections provide unbiased quality assessments throughout production. We arrange inspections during production, before packaging, and before shipment. This catches issues early when they’re still correctable, rather than finding problems after products arrive at your warehouse.

Always insist on pre-shipment sample approval. This is your final checkpoint before products leave the factory. We thoroughly test these samples against your specifications and only authorize shipment when everything meets standards.

Building strong supplier relationships is perhaps most important. When manufacturers view you as a valued long-term partner rather than a one-time customer, they prioritize your quality requirements. Our established relationships in Mexico, China, Vietnam, and other manufacturing regions give our clients this advantage from day one.

Regular communication, prompt payment, and treating suppliers with respect goes a long way toward ensuring they give your products the attention they deserve. This relationship-focused approach has served our clients well for over 40 years.

Conclusion: Build Your Brand with the Right Partner

Finding the right private label wholesalers isn’t just about getting products made – it’s about finding a manufacturing partner who truly understands your vision and can help bring it to life. Whether you’re developing innovative home improvement tools, cutting-edge sporting goods equipment, specialized automotive parts, or durable outdoor products, the partnership you choose will shape your brand’s future.

Throughout this guide, we’ve walked through seven proven strategies for finding quality manufacturers, from exploring B2B platforms and attending trade shows to leveraging professional networks and government resources. But remember, the real work begins after you’ve found potential partners. Due diligence is everything – evaluating their quality control processes, customization capabilities, and communication skills will save you headaches down the road.

The private label market’s explosive growth to over $1 trillion globally isn’t happening by accident. Smart businesses are realizing that working with private label wholesalers gives them something priceless: complete control over their brand story. You get to decide the quality, the features, the packaging, and ultimately, how customers experience your products.

At Altraco, we’ve spent over four decades building the kind of trusted factory relationships that make all the difference. Our expertise in offshore manufacturing across Mexico, China, Vietnam, and other key regions means we can steer the complexities that often trip up businesses new to global sourcing. Tariff navigation, quality control, and logistics coordination – we handle the technical details so you can focus on building your brand.

The beauty of working with experienced private label wholesalers is that you’re not starting from scratch. You’re tapping into established manufacturing expertise while maintaining the flexibility to create something uniquely yours. It’s the best of both worlds: proven production capabilities with unlimited creative potential.

Your customers are looking for products that solve their problems better than anything else on the market. With the right manufacturing partner, you can deliver exactly that – products that carry your brand name and reflect your commitment to quality and innovation.

Ready to transform your product ideas into a thriving private label brand? Start your private label journey with wholesale products and find how the right partnership can open up your business’s full potential.