Why Supply Chain Performance Goes Beyond the Bottom Line

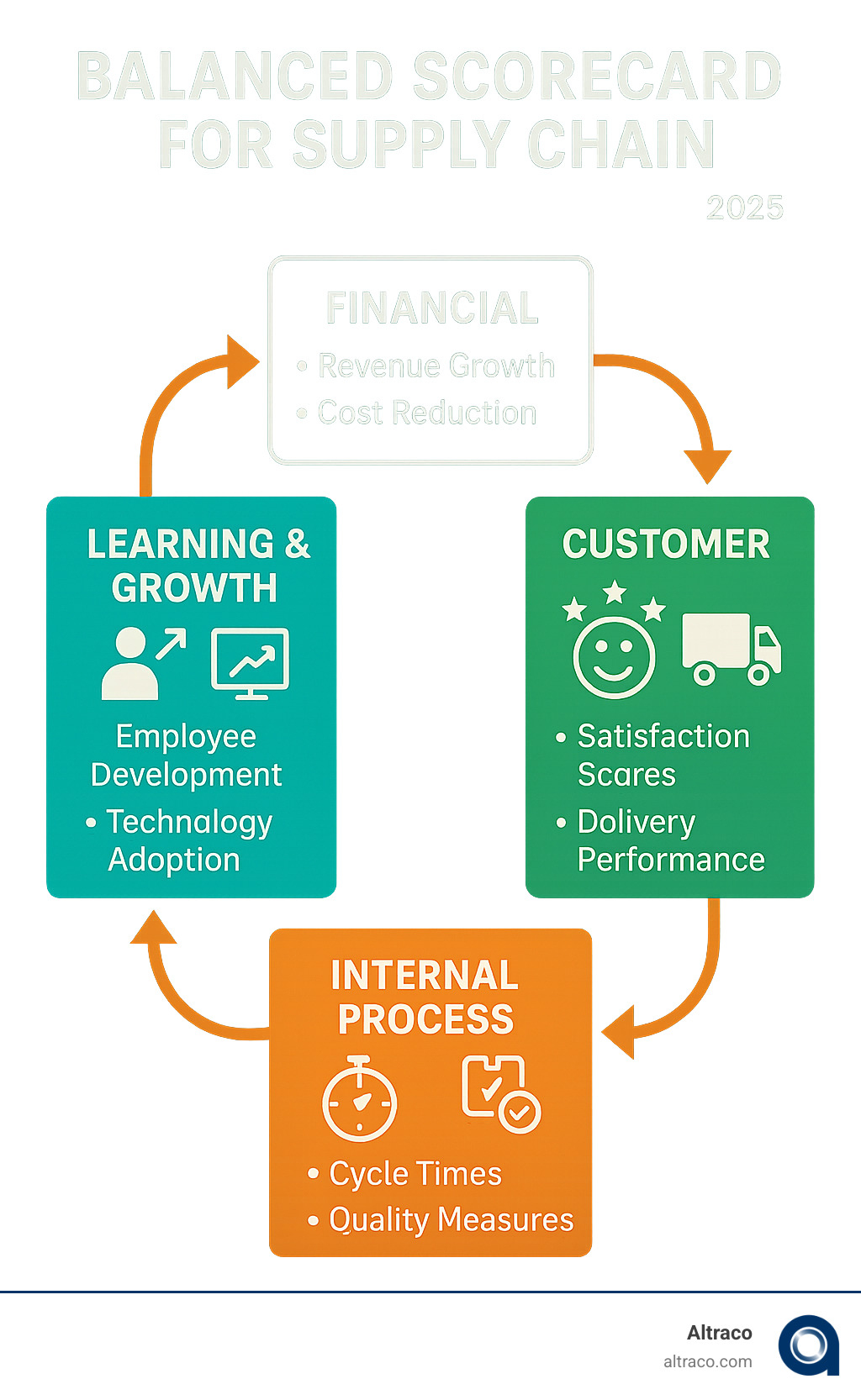

A balanced scorecard for supply chain management provides a comprehensive view of your operations, extending far beyond traditional financial metrics. This strategic framework, developed by Robert Kaplan and David Norton, helps organizations align supply chain activities with broader business objectives by measuring success across four key perspectives: Financial, Customer, Internal Process, and Learning & Growth.

Instead of relying solely on lagging financial indicators, a balanced scorecard connects day-to-day operations to your company’s vision, offering a holistic view that balances short-term results with long-term capabilities. This proactive approach provides early warning indicators before problems impact the bottom line, creating a shared language for performance across departments.

Have you ever ordered a product, only for it to arrive a day late? Or found an item out of stock at the store? These common frustrations reveal the complex forces at play in the global supply chain and highlight why measuring performance requires more than just tracking costs.

Companies using a balanced scorecard approach outperform their peers by 25%, while those actively monitoring comprehensive KPIs are 35% more likely to achieve their supply chain objectives. Yet many organizations still struggle with tracking too many disconnected metrics or rely on financial data that only shows problems after it’s too late.

I’m Albert Brenner, co-owner of a contract manufacturing company with 40 years of experience helping Fortune 500s manage global supply chains for home improvement, sporting goods, and automotive parts. Implementing balanced scorecard for supply chain frameworks in Mexico, China, and Vietnam, I’ve seen how this approach transforms operational performance.

Why a Balanced Scorecard is Crucial for Modern Supply Chain Management

Imagine your CEO asks for a performance update on your manufacturing operations across three continents. You present cost savings, but then come questions about customer satisfaction, quality, and future readiness. Suddenly, those financial numbers don’t tell the whole story.

This scenario is why a balanced scorecard for supply chain management is essential. Many companies drown in disconnected KPIs or focus solely on financial metrics, missing the bigger picture. The balanced scorecard, developed by Robert Kaplan and David Norton, solves this by linking four key performance areas directly to strategic objectives. It’s about building long-term supply chain health, not just immediate financial gains.

Real-world results speak for themselves. The case study on changing logistics from the Crane Army Ammunition Activity shows how a supply chain-focused balanced scorecard can transform performance and create competitive advantages.

For companies like ours at Altraco, managing complex manufacturing for home improvement parts in Mexico, sporting goods in Vietnam, and automotive components in China, this holistic approach is critical for balancing stakeholder expectations and enabling proactive problem-solving.

The Limits of Financial-Only Metrics

Financial metrics are great at telling you what happened last month but terrible at predicting what’s next. These lagging indicators are like looking in the rearview mirror—useful for context, but not for avoiding the obstacle ahead.

I’ve seen many companies fall into the “cost-cutting at all costs” trap. Switching to the cheapest shipping option looks great on paper. But three months later, when customer complaints about late deliveries and damaged products flood in, that “savings” proves costly. A short-term focus on financials ignores critical factors like quality and customer satisfaction, potentially eroding the foundation of your business.

This incomplete picture is even more problematic in global supply chains. A factory in China might show excellent cost performance by cutting corners on quality control, but you won’t see the impact until defective products reach customers weeks later.

Aligning Your Global Supply Chain with Company Strategy

The real power of a balanced scorecard for supply chain is its ability to translate your company’s vision into concrete, measurable actions. It creates clear cause-and-effect relationships that connect every operational decision to strategic outcomes.

For example, when your Vietnam facility improves manufacturing cycle time, how does that affect customer satisfaction? The balanced scorecard makes these connections explicit. For global manufacturing—whether producing outdoor products in Vietnam, automotive parts in Mexico, or home improvement components in China—this strategic alignment is crucial. Without it, you have disconnected KPIs that don’t contribute to overall success.

The framework also transforms cross-departmental communication. Instead of procurement, production, and logistics working in silos, everyone understands how their performance contributes to shared goals. Your quality manager in China knows how their improvements support customer retention, and your logistics coordinator in Mexico sees how on-time delivery connects to revenue growth.

The Four Perspectives: Mapping Your Supply Chain KPIs

Think of the balanced scorecard for supply chain as a compass with four cardinal directions, each pointing to a different aspect of business success. This framework creates a holistic measurement system where leading indicators (predicting future performance) and lagging indicators (measuring past results) provide a complete picture of your supply chain health.

The beauty of this approach is its interconnected nature. Improvements in one area, like employee training, lead to better internal processes, which improve customer satisfaction and ultimately drive financial performance.

Financial Perspective: Measuring Profitability and Efficiency

This perspective answers: “How do we look to shareholders?” It demonstrates how supply chain operations contribute to the company’s bottom line. Key metrics include:

- Cost reduction: Track supply chain cost as a percentage of sales to measure efficiency. Effective BSC implementation can reduce inventory costs by 20%.

- Asset utilization: Metrics like inventory turnover show how well you’re using capital. A higher turnover means less cash is tied up in stock.

- Cash-to-cash cycle time: This is crucial for overseas manufacturing. It measures the time to convert cash invested in materials back into cash from sales.

- Return on investment (ROI): Justifies new technologies or initiatives, proving the value of investments in your supply chain. In our experience, strengthening supplier relationships often delivers significant cost improvements.

Customer Perspective: Delivering Value and Satisfaction

This perspective asks: “How should we appear to our customers?” It focuses on exceeding customer expectations to build loyalty and improve brand reputation. Key metrics include:

- On-time delivery (OTD): Measures the percentage of orders delivered by the promised date. A 1-2% improvement can translate into millions in retained revenue.

- Perfect order rate: Tracks orders delivered complete, on time, damage-free, and with accurate documentation. A rate over 95% builds a strong brand reputation.

- Customer satisfaction scores (CSAT): Provides direct feedback on the customer experience.

- Order fulfillment cycle time: Reducing this time from order to delivery directly boosts customer satisfaction. For complex products, quality is paramount. We have proven strategies for managing quality issues in manufacturing.

Internal Business Process Perspective: Optimizing Your Operations

This perspective addresses: “What must we excel at?” It focuses on optimizing the core processes that create value. Key metrics include:

- Manufacturing cycle time: The duration from planned order to final production. Optimizing this is critical when coordinating production across countries like Mexico, China, and Vietnam.

- Inventory turnover ratio: Helps find the balance between meeting demand and minimizing holding costs.

- Supplier lead time: We regularly assess supplier performance to ensure reliability, especially for products with seasonal demand.

- Warehouse efficiency: Includes metrics like storage occupancy, order picking accuracy, and shipping accuracy.

- Production quality: Essential for industries like automotive parts. Track defect rates, rework, and adherence to standards. Our approach to maintaining a Quality Control Program ensures these metrics stay in range.

Learning and Growth Perspective: Fueling Future Success

This perspective asks: “How can we continue to improve?” It focuses on the intangible assets that fuel innovation—your people, technology, and culture. Key metrics include:

- Employee skills and training: Investing in training hours and certifications builds capabilities. Companies using BSC often see a 75% increase in employee engagement.

- Technology adoption: The rate of implementing tools like AI for forecasting or IoT for tracking directly impacts your competitive edge.

- Continuous improvement culture: Measured by the number of process improvements implemented. 60% of companies with these programs report significant revenue growth.

- Supplier collaboration: Joint planning and innovation with manufacturing partners create hard-to-replicate advantages. The value of strong buyer-supplier relationships extends beyond cost savings to innovation and risk mitigation.

- Information systems capabilities: Robust data infrastructure is essential for real-time decision-making across global operations.

A 5-Step Guide to Implementing Your Balanced Scorecard for Supply Chain

Implementing a balanced scorecard for supply chain is a systematic process of continuous improvement. By breaking it down into manageable steps, you can successfully translate your strategy into action.

Step 1: Define Your Strategic Supply Chain Objectives

Before you can measure success, you must define it. Start by asking: What does supply chain success mean for our business? Your objectives must connect directly to your overall business strategy. For example, if your company aims to be a top brand for outdoor enthusiasts, a supply chain objective might be to “Reduce lead times for outdoor products from Vietnam by 15% while maintaining quality.” These goals should be stepping stones toward your larger business vision, whether for automotive parts, sporting goods, or home improvement products.

Step 2: Map Objectives and Select Your KPIs

Next, assign your strategic objectives to the four balanced scorecard for supply chain perspectives. Then, choose the Key Performance Indicators (KPIs) that will measure your progress. Avoid “metric madness” by focusing on what matters. Instead of tracking everything, concentrate on high-impact indicators that drive decisions. For instance, focus on inventory turnover for critical, high-value items rather than every component. Supplier Scorecards are valuable tools for selecting KPIs related to supplier performance that directly impact your internal and financial outcomes.

Step 3: Set Targets and Establish Baselines

To set meaningful targets, you first need to understand your current performance. This baseline allows you to set realistic but challenging goals that motivate your team. Industry benchmarking is crucial here. If your on-time delivery rate is 90%, aiming for 95% is a significant commitment requiring cross-functional improvements. For manufacturing automotive parts in China, we might set targets for reducing defect rates that require both process and quality control improvements. These targets become rallying points that encourage ownership across the supply chain.

Step 4: Implement, Monitor, and Communicate

Bring your scorecard to life with clear dashboards that visualize your KPIs for at-a-glance monitoring. Invest in tools that integrate data and automate reporting, freeing up your team for analysis. Regular review meetings, such as Sales & Operations Planning (S&OP), provide a forum for cross-functional teams to discuss performance and develop solutions. Transparent communication is essential. When everyone understands how their work contributes to the bigger picture, and when KPIs are discussed at leadership meetings, the system gains traction and importance.

Step 5: Review and Refine for Continuous Improvement

Your balanced scorecard for supply chain must be a living tool that evolves with your business. Market conditions, technology, and customer expectations change, and your measurement system must keep pace. Regular reviews ensure your KPIs remain relevant. For companies managing manufacturing across Mexico, China, and Vietnam, this flexibility is vital as global conditions shift. This refinement process fosters a culture of improvement, changing your organization from reactive problem-solvers to proactive performance optimizers. Integrating proven tips to improve quality in overseas manufacturing into this cycle can yield significant benefits across all four BSC perspectives.

Overcoming Common Challenges in BSC Implementation

Implementing a balanced scorecard for supply chain has its challenges, but they are manageable with proactive planning. After four decades helping companies manage global supply chains—from automotive parts in Mexico to sporting goods in Vietnam—I’ve seen these pitfalls repeatedly. Recognizing them early is key.

Challenge 1: Data Availability and Quality

Do different departments report conflicting data on the same metric? Welcome to data silos, where fragmented information makes accurate measurement nearly impossible. Inaccurate information leads to poor decisions and undermines the entire BSC system.

- Solution: Integrate Systems. Invest in an Enterprise Resource Planning (ERP) system or other tools to create a “single source of truth” where everyone can find consistent, reliable data.

- Solution: Establish Data Governance. Create clear policies for how data is collected, stored, and maintained. This ensures consistency and builds trust in your metrics.

Challenge 2: Cultural Resistance and Lack of Buy-In

Resistance to new measurement systems is common, often stemming from a fear of being judged or a “this is not my job” mentality. When teams see the scorecard as extra work rather than a helpful tool, they may resist its implementation.

- Solution: Secure Executive Sponsorship. When leadership actively champions the BSC, it signals its importance to the entire organization. Half-hearted support is a recipe for failure.

- Solution: Communicate the “Why”. Help your team understand how the scorecard makes their jobs easier by providing clarity and preventing last-minute fire drills.

- Solution: Involve Teams in the Process. When people help select the metrics that measure their performance, they gain a sense of ownership and are more likely to accept the system.

Challenge 3: Overly Complex Scorecards

Initial enthusiasm can lead to creating a scorecard with dozens of KPIs, resulting in the very analysis paralysis the BSC was designed to prevent. When everything is a priority, nothing is. Your team will spend more time generating reports than acting on insights.

- Solution: Focus on the Critical Few. Quality beats quantity. Start with 12-15 core KPIs across all four perspectives that align with your strategic objectives.

- Solution: Use Clear Visualizations. Present data in easy-to-understand dashboards with visual cues like traffic light systems (red, amber, green) to show performance status at a glance.

- Solution: Start Simple and Evolve. Don’t aim for perfection on day one. Begin with a manageable set of metrics and expand the scorecard as your team’s capability and confidence grow. The best scorecard is one that is used consistently.

Conclusion: Achieve Strategic Alignment and Global Success

Behind every exceptional customer experience—a package arriving on time, a product exceeding expectations—is a supply chain guided by clear metrics and strategic alignment. The balanced scorecard for supply chain moves performance measurement from a reactive, backward-looking exercise to a proactive, forward-looking strategy. It creates a powerful bridge between daily operations and long-term success.

The Power of Holistic Performance Management

By measuring across the Financial, Customer, Internal Process, and Learning & Growth perspectives, you stop making trade-offs between short-term savings and long-term health. Instead, you find ways to improve efficiency while enhancing quality and reduce costs while increasing customer satisfaction. This holistic approach drives continuous improvement and connects every team member’s contribution to the organization’s goals.

Navigating Global Manufacturing Complexity

For companies managing offshore manufacturing—whether producing home improvement hardware in Mexico, sporting goods in China, or automotive parts globally—a balanced scorecard for supply chain provides essential clarity. It helps you maintain focus on strategic objectives while adapting to the daily realities of international trade, from currency fluctuations to shipping delays.

At Altraco, our decades of experience managing global supply chains, combined with trusted factory relationships and tariff navigation expertise, allow us to help companies implement meaningful performance measurement systems. We ensure every metric drives a better decision.

Your Path Forward

The journey to supply chain excellence is about building a foundation for continuous improvement and transparency. A well-designed balanced scorecard provides the roadmap. Ready to transform your supply chain performance? Open up your supply chain’s potential with Supplier Scorecards and find how strategic measurement can drive real results in your global operations.