Why Global Production Strategy is the Foundation of International Competitiveness

Global production strategy is the plan that determines where a company manufactures products, sources materials, and delivers goods to customers worldwide. A well-designed strategy can:

- Reduce costs by 20% to 50% through optimized manufacturing and supply chains.

- Improve resilience by diversifying production and mitigating supply chain disruptions.

- Accelerate market entry by locating production near key customers.

- Boost competitiveness by leveraging lower labor costs, specialized skills, and favorable trade policies.

- Increase shareholder value by as much as 80% over ten years compared to companies without strong global strategies.

The global manufacturing landscape is changing rapidly. Recent disruptions like trade wars, the pandemic, and evolving tariff policies have forced companies to rethink where and how they produce goods. Today, many of the world’s largest manufacturers are changing their production footprints, with a significant number shifting production to their home or neighboring countries.

This shift involves making strategic choices between exporting, local assembly, and full local production. It requires understanding the trade-offs between cost, speed, quality, and risk, and navigating complex factors like labor productivity, infrastructure, and political stability across potential manufacturing locations.

As a contract manufacturer with decades of experience, we’ve helped companies steer these exact challenges—from automotive parts to sporting goods—by establishing reliable production in Mexico, China, Vietnam, and beyond. This guide will break down the essential components of a successful global production strategy and show you how to make informed decisions about where and how to manufacture your products.

What is a Global Production Strategy and Why is it Crucial?

A global production strategy is a roadmap for manufacturing and delivering products across international borders. It balances global consistency with local market needs to drive competitiveness and growth, making it a critical component of any international business strategy.

A strong strategy offers many benefits:

- Competitiveness: Strategic production placement leverages cost advantages, specialized labor, and proximity to raw materials.

- Economies of scale: Consolidating production for multiple markets leads to significant cost reductions per unit.

- Market share growth: An effective strategy allows for efficient entry into new markets, which can increase shareholder value by as much as 80% over peers in ten years.

- Brand recognition: Consistent quality and availability across markets strengthen a brand’s global standing.

- Risk diversification: Spreading production across different regions mitigates risks from economic or political instability in a single location.

- Cost efficiency: Optimizing supply chains and production locations significantly reduces manufacturing and logistics expenses.

Altraco’s International Sourcing Services are designed to help businesses harness these advantages by finding the right partners and locations for their unique needs.

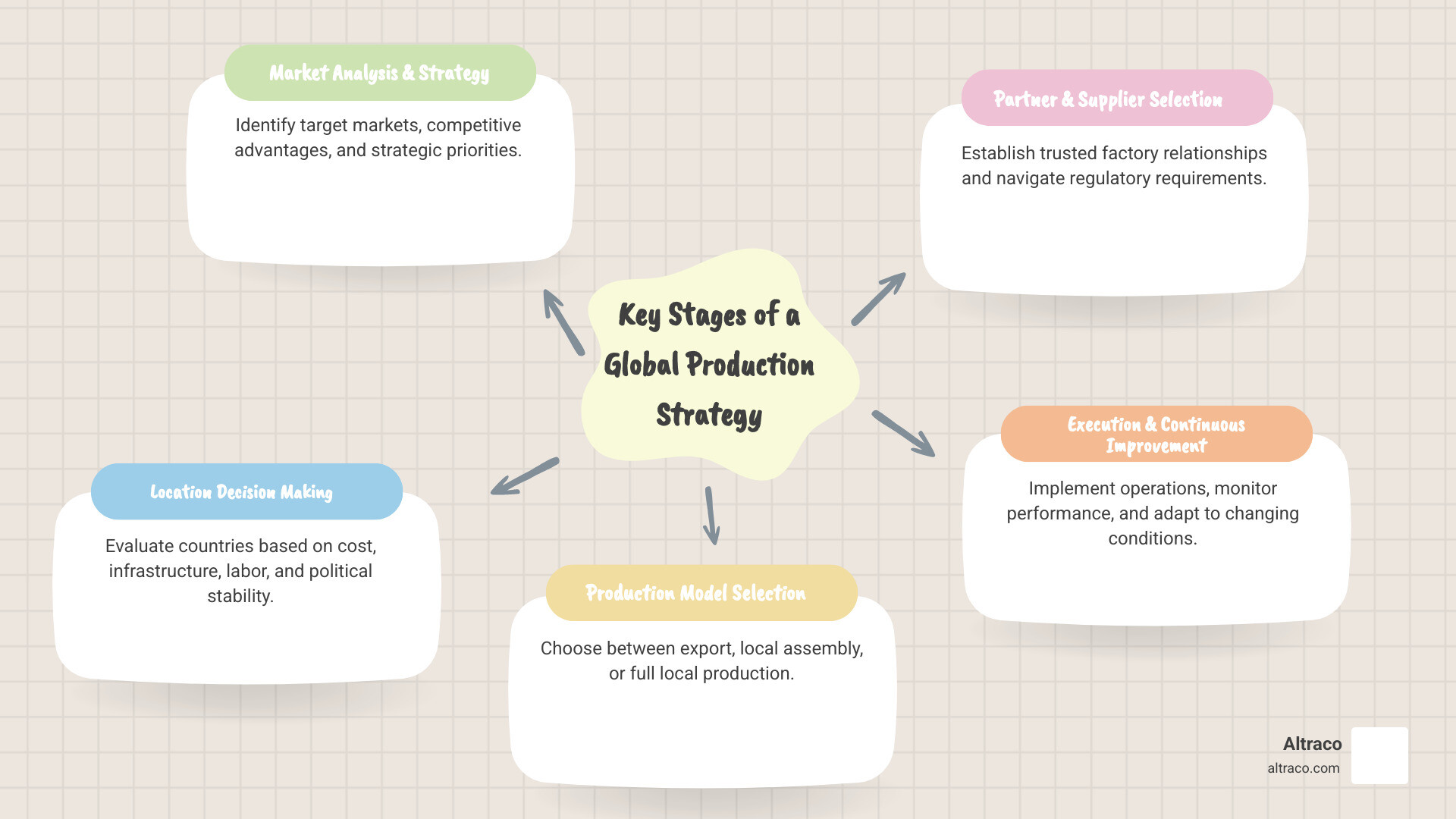

The Core Components of a Global Strategy

A robust global production strategy integrates several interconnected components:

- Product development: Designing products with universal appeal while allowing for local adaptations and maintaining consistent quality standards.

- Product positioning: Defining how products are perceived in each market, which includes branding and differentiation. Consistent branding can lead to 20% more overall growth and 33% higher revenue.

- Global branding: Creating a unified identity that resonates worldwide.

- Distribution logistics: Managing the supply chain to move products from the factory to the customer efficiently.

- Pricing strategy: Setting competitive and profitable prices across different economic landscapes.

- Product support: Providing excellent after-sales service and support regardless of customer location.

These elements are interdependent; a decision in one area, like material sourcing, can impact others, such as logistics.

The Role of Operations and Product Management

Executing a global production strategy requires close collaboration between product management and operations management.

Product management oversees the product lifecycle, from market research and developing specifications to coordinating between departments and monitoring performance. They define what needs to be made and why.

Operations management ensures the production process runs smoothly. They focus on efficiency, quality standards, timely delivery, and managing the global supply chain. They determine how products will be made and delivered efficiently.

The interplay is crucial. For example, if product management identifies a demand for a new eco-friendly home improvement product, operations management sources sustainable materials and establishes appropriate manufacturing processes.

Altraco’s expertise in Integrated Supply Chain Services ensures these two functions are perfectly aligned, translating product vision into high-quality, cost-effective realities for our clients worldwide.

Core Strategic Choices in a Global Production Strategy

When taking products to the global stage, companies face fundamental choices about where and how to produce them. These decisions involve significant considerations of risk, reward, investment, and market entry. The path chosen for producing sporting goods or automotive parts will shape the entire global footprint.

Production Models: Export, Local Assembly, and Local Production

Companies typically choose from three primary production models, each with distinct trade-offs.

| Strategy | Cost Considerations | Control Over Operations | Market Responsiveness | Risk Profile |

|---|---|---|---|---|

| Exporting | Lower initial investment, higher logistics costs | High (centralized production) | Lower (distance, trade barriers) | Lower political risk, higher shipping/tariff risk |

| Local Assembly | Moderate investment, potential tax/tariff incentives | Moderate (some local control, but core components imported) | Moderate to High (closer to market) | Moderate (some political risk, coordination challenges) |

| Local Production | High initial investment, potential lower operational costs | Lower (local management, potential cultural differences) | High (fully integrated into local market) | Higher (political, economic, regulatory, IP protection) |

- Exporting from the home country: This is the simplest, lowest-risk approach for initial market entry. Products are made in existing facilities and shipped internationally. Advantages include high control over quality and IP with lower initial investment. Disadvantages include high transport costs, tariffs, and longer lead times.

- Global components with local assembly: Core components are made centrally (e.g., in China or Vietnam) and shipped to the target market for final assembly. Advantages include potential tax incentives and improved market responsiveness. Disadvantages involve coordination challenges and potential quality control issues.

- Full local production: This involves establishing complete manufacturing facilities in the foreign market. Advantages include maximum market responsiveness, significant cost savings, and access to local knowledge. Disadvantages are high initial investment and increased exposure to political and economic risks.

Outsourcing vs. Offshoring: Making the Right Choice

Understanding the difference between outsourcing and offshoring is crucial for an effective global production strategy.

- Outsourcing: Delegating a business process, like manufacturing, to an external vendor. This provides access to specialized expertise and reduces operational costs, allowing a company to focus on core competencies like design and marketing.

- Offshoring: Setting up your own operations in a low-cost country to retain control while benefiting from lower labor rates. This offers significant cost savings and direct oversight of processes and quality.

Altraco specializes in contract manufacturing and private label manufacturing, which often blend these concepts. As an offshore contract manufacturer, we simplify global supply chains by leveraging our trusted factory relationships in Mexico, China, and Vietnam. This allows clients to gain the benefits of overseas production without the complexities of managing their own offshore facilities, a key consideration in today’s environment as highlighted in The New Dynamics of Global Manufacturing Site Location. This is especially relevant for nearshoring to Mexico, as discussed in Why Mexico Manufacturing is Changing Global Supply Chains.

Key Factors Influencing Your Global Production Strategy

Choosing the right manufacturing location requires balancing cost, quality, speed, and risk. Key factors we evaluate include:

- Economic and political stability: A predictable environment is crucial for long-term investment.

- Tariffs and trade policies: Import/export duties and trade agreements significantly impact landed costs. Recent US Supreme Court decisions on tariffs highlight the volatility in this area.

- Labor costs and skills: We assess not just wages but also productivity and the availability of skilled labor for industries like home improvement or automotive parts.

- Infrastructure quality: Reliable transport, power, and telecommunications are non-negotiable.

- Proximity to markets and raw materials: Closer proximity reduces costs and lead times.

- Regulatory environment: We steer local business laws, environmental regulations, and IP protection.

- Government incentives: Many countries offer tax breaks or subsidies to attract investment.

Making these decisions requires a careful balancing act, as explored in Supply Chain Globalization: Is It Worth the Risk?. It’s about aligning choices with long-term strategic goals.

Navigating Challenges and Leveraging Technology

Implementing a global production strategy involves navigating regulatory compliance, cultural differences, and supply chain disruptions. Geopolitical tensions and crises are reshaping manufacturing footprints, demanding agility and adaptation, as explored in Harnessing the Tectonic Shifts in Global Manufacturing. Our Case Studies show how we’ve helped clients tackle these challenges, from shipping delays for outdoor products to quality control for automotive parts across continents.

Common Problems in Implementation

Executing a global strategy presents recurring problems that can impact cost, timelines, and quality.

- Tariff navigation: Complex tariffs and customs regulations can add substantial costs and delays. Navigating these, especially with recent trade policy shifts and US Supreme Court decisions, is paramount.

- Intellectual property protection: Safeguarding designs for sporting goods or automotive parts in foreign countries is challenging. We ensure robust IP protection through our trusted factory relationships.

- Quality control across borders: Maintaining consistent quality standards across continents like Asia and North America requires rigorous oversight. Our quality programs ensure products meet exact specifications.

- Communication barriers: Language, time zones, and cultural differences can cause misunderstandings. Clear communication protocols are essential.

- Supply chain disruptions: Global events can disrupt supply chains. We build resilience through supplier diversification and contingency planning.

Understanding key terms is a foundational step, as detailed in Understanding Manufacturing Terminology in the Global Supply Chain.

Executing a Modern Global Production Strategy with Technology

Today, technology is the backbone of a modern global production strategy, enabling precision, efficiency, and responsiveness.

- Data analytics: Analyzing operational data provides insights to optimize processes and make data-driven decisions. 90% of global executives report that data analytics improves their ability to deliver superior customer experiences.

- AI in supply chains: Artificial intelligence helps predict demand, manage inventory, and optimize logistics, anticipating disruptions and suggesting optimal shipment routing.

- Automation in manufacturing: Robotics and automated quality checks improve precision, speed, and consistency while reducing costs.

- Real-time visibility: Technology offers a complete, live view of the global supply chain, from raw materials to final delivery, enabling proactive problem-solving.

- Predictive modeling: Simulating scenarios like new tariffs or demand surges helps optimize strategies in advance.

Embracing these tools ensures our strategies are proactive and resilient. Our Balanced Scorecard for Supply Chain approach integrates these insights into performance management.

Frequently Asked Questions about Global Production Strategy

How do companies decide where to locate production facilities?

Deciding on a production location is a critical part of a global production strategy. It involves a thorough analysis to balance cost, risk, and market responsiveness. Key factors include:

- Labor costs, skills, and availability for industries like home improvement or automotive parts.

- Political and economic stability.

- Quality of infrastructure (transport, power, communications).

- Proximity to markets and raw materials.

- Tariffs, trade policies, and the impact of events like US Supreme Court decisions.

- Government incentives and IP protection laws.

Many companies now use a “China plus one” strategy, diversifying production to mitigate risk. This often includes nearshoring to countries like Mexico for the North American market, leveraging its proximity and manufacturing capabilities for sectors like automotive parts and home improvement.

What is the difference between a global product and a global marketing strategy?

While intertwined, these strategies have distinct functions:

- A global product strategy covers what is produced and where. It includes product design (e.g., for sporting goods), manufacturing processes, quality control, and facility location. It’s about creating the product efficiently and to a high standard.

- A global marketing strategy covers how the product is sold. This includes branding, advertising, pricing, and distribution. It’s about communicating the product’s value and adapting the message to local cultures.

For success, these strategies must be aligned. The product strategy creates a high-performance outdoor product, and the marketing strategy tells the world why they should buy it.

How can a smaller business implement a global production strategy?

Implementing a global production strategy is achievable for smaller businesses with the right approach.

- Start with exporting: This is the lowest-risk option for initial market entry, allowing you to test international demand without significant foreign investment.

- Partner with a contract manufacturing expert: This is a highly strategic move. A partner like Altraco simplifies the process by providing access to established offshore contract and private label manufacturing services. We offer:

- Trusted factory relationships in key regions like Mexico, China, and Vietnam.

- Rigorous quality control processes to ensure products meet your specifications.

- Tariff navigation expertise to handle complex trade regulations.

- Significant cost savings through optimized production and supply chains.

- Focus on niche markets: Identify specific unmet needs in international markets.

- Leverage technology: Use digital tools for market research and supply chain visibility.

Partnering with an experienced firm like Altraco minimizes risk and investment, accelerates market entry, and provides access to global manufacturing capabilities. This allows you to focus on your core business while we simplify your global supply chain.

Conclusion

The global manufacturing landscape is constantly changing, making a well-defined and agile global production strategy essential for international success. A robust strategy drives competitiveness by balancing core components like product development and logistics, and making smart choices between models like exporting, local assembly, or full production.

Navigating challenges such as tariff complexities and quality control requires expertise, while leveraging technology like data analytics and AI creates opportunities for innovation. Success hinges on flexibility, informed decision-making, and adapting to the changing environment.

This is where a strategic partnership becomes invaluable. At Altraco, we simplify global supply chains for businesses of all sizes, from Fortune 500s to emerging brands. We help clients steer strategic decisions for production in countries like Mexico, China, and Vietnam. Whether you’re manufacturing home improvement products, sporting goods, or automotive parts, our decades of experience, trusted factory relationships, and tariff navigation expertise turn your production strategy into a competitive advantage.

Ready to optimize your global production and ensure consistent quality? Learn how to Maintain a Quality Control Program for your global production.