Why Modern Businesses Need Effective Inventory Control

Inventory management solutions are essential software systems that help businesses track, control, and optimize their stock. They provide real-time stock tracking, automate order management, optimize costs, and integrate with other business platforms like accounting and e-commerce. Through robust reporting and analytics, these systems offer critical insights into sales trends and turnover rates.

Managing physical goods is a balancing act: too much inventory ties up cash, while too little leads to lost sales. This challenge intensifies with global supply chains, which introduce longer lead times, complex tariff calculations, and the need to coordinate stock across multiple countries.

Modern inventory solutions replace inefficient spreadsheets with automation and real-time visibility, enabling smart purchasing decisions. For enterprises working with contract manufacturers in countries like China, Vietnam, and Mexico, these systems are vital for controlling costs and ensuring on-time delivery.

I’m Albert Brenner, and with over 40 years of experience in offshore contract manufacturing, I’ve seen how these solutions boost profitability. Whether you’re producing automotive parts, sporting goods, or home improvement products, the right inventory system is key to bridging overseas production with domestic distribution.

Understanding Core Functionalities and Benefits

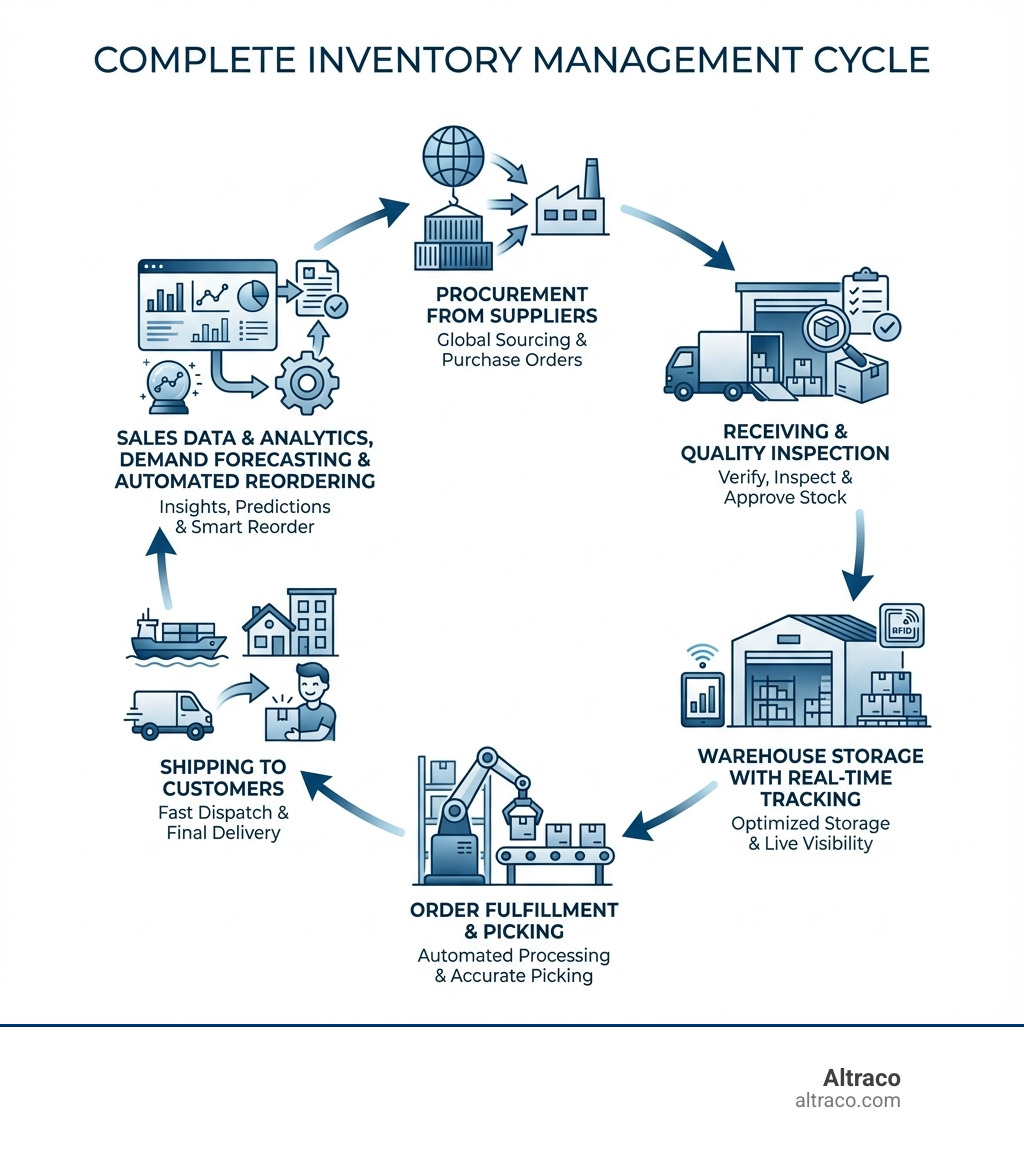

A robust inventory management solution provides unparalleled control and visibility, moving businesses beyond error-prone spreadsheets. The core functionalities are designed to handle every stage of your product’s journey, from procurement to fulfillment.

Key Software Features Explained

These are the tools that empower businesses to manage global supply chains, from offshore contract manufacturing to final delivery in the U.S.

- Real-time Inventory Tracking: Know the exact quantity and location of every item, whether it’s on a container from China or on a shelf in a Thousand Oaks warehouse. The system updates instantly as items are sold, received, or moved.

- Order Management and Automation: From creating purchase orders (POs) to managing sales orders, this automates procurement and fulfillment. Features like low-stock alerts and automatic reorder points prevent stockouts by notifying you when stock hits a minimum and even generating POs automatically.

- Barcode and QR Code Scanning: Speed up inventory counts, receiving, and dispatching while reducing human error. Many solutions offer in-app scanners for mobile devices.

- Multi-Warehouse Support: For businesses with multiple locations, such as a distribution center in Long Beach, CA, and a fulfillment center in Thousand Oaks, this feature allows for centralized management and real-time visibility across all sites.

- Kitting and Bundling: Essential for selling grouped items, like home improvement kits or outdoor product bundles. The software automatically adjusts the inventory of component parts when a kit is sold.

- Batch and Serial Number Tracking: For products requiring high traceability, like automotive parts, this tracks items by specific batches or serial numbers from procurement to sale, which is crucial for quality control.

- Reporting and Analytics: Transform data into actionable insights. Generate custom reports for audits, budgeting, and forecasting to get a clear picture of inventory performance.

- Mobile App Access: Manage inventory on the go, even offline. This is a game-changer for warehouse teams or staff performing field audits.

By leveraging these functionalities, businesses optimize stock levels, reduce costs, and avoid both overstocking and understocking.

The Role of Technology: Barcodes and RFID

Efficiency and accuracy are paramount in inventory management. This is where technologies like barcodes and RFID tags revolutionize how we track goods.

Barcode Technology is a cost-effective way to identify and track items. A quick scan updates inventory records, speeding up receiving and reducing the human error associated with manual data entry.

RFID (Radio-Frequency Identification) Technology takes tracking a step further. Using radio waves, RFID tags can be read from a distance without a direct line of sight, allowing for instantaneous scanning of entire pallets. This is ideal for high-value items like automotive parts and provides superior “dock to delivery” visibility, tracking goods from a contract manufacturer in Mexico to a warehouse in Thousand Oaks, CA.

How to Choose the Right Inventory Management Solutions

Choosing the right inventory management solutions requires matching software capabilities to your unique business needs, especially when navigating the complexities of offshore contract manufacturing.

When evaluating software, focus on these key considerations:

- Scalability: Will the software grow with you? It should handle increased inventory, more locations, and a larger user base without a complete overhaul.

- Integration Capabilities: How well does it connect with your existing accounting, POS, or e-commerce platforms? Seamless integration is crucial for a unified view of your operations.

- Total Cost of Ownership (TCO): Look beyond the sticker price to include implementation, subscription fees, training, and maintenance.

Selecting the Best Solution for Your Business

The right choice often depends on your company’s size and complexity.

- For small businesses, ease of use and affordability are key. Many start with free, built-in POS features or free plans from software providers. These are great for transitioning away from error-prone spreadsheets.

- For large enterprises, requirements are more robust. Comprehensive ERP systems integrate inventory with finance and manufacturing, built to handle vast inventories, multiple warehouses, and complex reporting.

Another choice is between cloud-based vs. on-premises deployment. Cloud solutions offer remote accessibility and lower upfront costs, which is ideal for managing global supply chains. On-premises options provide more control but come with higher costs for hardware and maintenance.

Pricing models vary, from free tiers to thousands per month, typically based on the number of users, locations, features, and order volume. Always use free trials to evaluate a solution before committing.

Considerations for Different Business Models

Different business models have distinct inventory needs.

- Retail: Requires tight POS and e-commerce integration for real-time stock updates across all sales channels.

- Manufacturing: Needs advanced features like Bill of Materials (BOM) to track raw materials and Work in Process (WIP) tracking for items on the production floor. This is paramount for producing automotive parts or sporting goods.

- Distribution and Wholesale: Focuses on multi-warehouse management to track stock across various locations and requires deep integration with shipping carriers for efficient fulfillment.

Global Manufacturing and Inventory Considerations

For businesses using offshore contract manufacturing, inventory management solutions are even more critical. Managing a global supply chain with partners in China, Vietnam, or Mexico introduces challenges like longer lead times and complex customs regulations.

A key factor is tariff navigation. A robust system must track tariffs to calculate landed costs accurately, which is vital for profitability. Recent United States Supreme Court decisions on tariffs highlight how quickly these factors can change. The software should also support multi-currency transactions for accurate financial reporting.

The right solution provides the real-time visibility needed to monitor shipments, manage stock across international and domestic warehouses, and mitigate the risks of global logistics.

Advanced Inventory Techniques and System Integration

Beyond basic tracking, inventory management solutions enable advanced strategies to optimize your business. These tools help you predict demand, manage slow-moving stock, and streamline the returns process. By analyzing historical sales data and market trends, you can use demand forecasting to place smarter orders with contract manufacturers in China or Vietnam, ensuring you have enough automotive parts or home improvement products without overstocking.

Inventory Valuation Methods Explained

How you value inventory is crucial for financial reporting. Inventory management solutions support various methods, and an authoritative guide on inventory valuation can provide deeper insight.

| Method | Description | When Most Appropriate |

|---|---|---|

| First-In, First-Out (FIFO) | Assumes the first items purchased are the first sold. | Ideal for perishable goods or products with a short shelf life. |

| Last-In, First-Out (LIFO) | Assumes the last items purchased are the first sold. | Used to reduce taxable income during rising costs, but not allowed under IFRS. |

| Weighted Average Cost | Calculates an average cost for all inventory. | Best for identical products where individual costs are hard to track. |

| Standard Cost | Uses an estimated cost for accounting records, tracking variances. | Common in manufacturing for budgeting and cost control. |

| Specific Identification | Assigns a specific cost to each individual item. | Most appropriate for high-value, unique items like custom outdoor equipment. |

Understanding these methods helps accurately report costs, especially when dealing with fluctuating material prices or tariffs on goods from overseas.

Integrating Your Systems for a Unified View

The true power of inventory management solutions is open uped through integration with other business systems, creating a single source of truth.

- Accounting Integration: Automatically updates your Cost of Goods Sold (COGS) and simplifies invoicing when an item is sold.

- E-commerce and POS Integration: Syncs stock levels in real-time across all online and physical sales channels, preventing overselling.

For us, managing complex supply chains from offshore manufacturing to distribution in California, this unified view is non-negotiable. To learn more, explore our integrated supply chain services.

Managing Inventory for Peak Seasons

Effective inventory management is critical during peak sales periods.

- Forecasting: Use historical data to anticipate seasonal demand for products like sporting goods and plan manufacturing orders with offshore partners accordingly.

- Dynamic Reorder Points: Adjust reorder thresholds to account for higher sales velocity, ensuring you have enough lead time for shipments from overseas.

- Flexible Strategies: Use dropshipping to fulfill orders directly from a supplier or backordering to capture sales for temporarily out-of-stock items.

Frequently Asked Questions about Inventory Management

What is the difference between inventory management and asset management?

Inventory management tracks items for sale or production (e.g., raw materials, finished goods), which are consumed by the business. Asset management tracks long-term internal company property used for operations, such as computers, machinery, or vehicles, which are not sold to customers.

How much does inventory management software cost?

The cost of inventory management solutions varies from free to thousands of dollars per month.

- Free/Basic Plans: Some POS systems and software providers offer free tiers for small businesses with basic needs.

- Subscription Models: Most cloud solutions charge a monthly fee (e.g., $50-$300) based on users, locations, and order volume.

- Enterprise Solutions: Comprehensive ERP systems have higher costs, often requiring custom quotes and implementation fees.

Pricing depends on the number of users, locations, features, and transaction volume. Many providers offer free trials to test their software.

What is Just-in-Time (JIT) inventory?

Just-in-Time (JIT) is a strategy to minimize inventory costs by receiving goods from suppliers only as they are needed for production or sale. This approach reduces warehousing needs and waste but requires precise supply chain coordination, strong supplier relationships (like those with contract manufacturers in China or Mexico), and a robust inventory management solution to prevent production delays.

Conclusion: Taking Control of Your Supply Chain

In today’s business environment, effective inventory management solutions are a strategic imperative. They provide crucial visibility to streamline operations, optimize stock levels for significant cost savings, and improve customer satisfaction through reliable product availability. The future points toward even smarter, AI-driven supply chains.

For businesses navigating the complexities of global manufacturing—from producing automotive parts to outdoor equipment—partnering with an expert like Altraco simplifies the entire process. Our experience with factories in China, Vietnam, and Mexico, combined with our tariff navigation expertise, ensures your supply chain is optimized for cost-effectiveness and resilience. To build a more resilient and cost-effective global supply chain, explore our integrated supply chain services.