Why Advanced Order Management Matters for Modern Business

Advanced order management is a system that automates and optimizes how businesses handle orders across multiple channels, locations, and fulfillment points. Here’s what makes it essential:

- Centralized Control: Manage orders from e-commerce, phone, and POS systems in one place

- Intelligent Allocation: Automatically assign inventory from the best location based on cost, speed, or proximity

- Omnichannel Fulfillment: Support ship-from-store, store pickup, and mixed fulfillment strategies

- Exception Management: Automate handling of inventory discrepancies and shipping issues

- Global Visibility: Real-time view of inventory and orders across all warehouses and locations

Customer expectations and supply chain complexity have never been higher. Shoppers expect prompt, flexible fulfillment, like buying online and picking up in-store or shipping from the nearest location. Meanwhile, businesses are juggling inventory across multiple warehouses, retail stores, and third-party logistics providers—often spanning different continents.

For large enterprises manufacturing products like automotive parts, sporting goods, or home improvement items, the challenge multiplies. This isn’t just about retail orders; it’s about coordinating production with factories in Mexico, China, or Vietnam, navigating tariffs, managing phased rollouts, and ensuring on-time delivery to Fortune 500 clients.

The stakes are simple: deliver the perfect order every time, or risk losing customers and revenue.

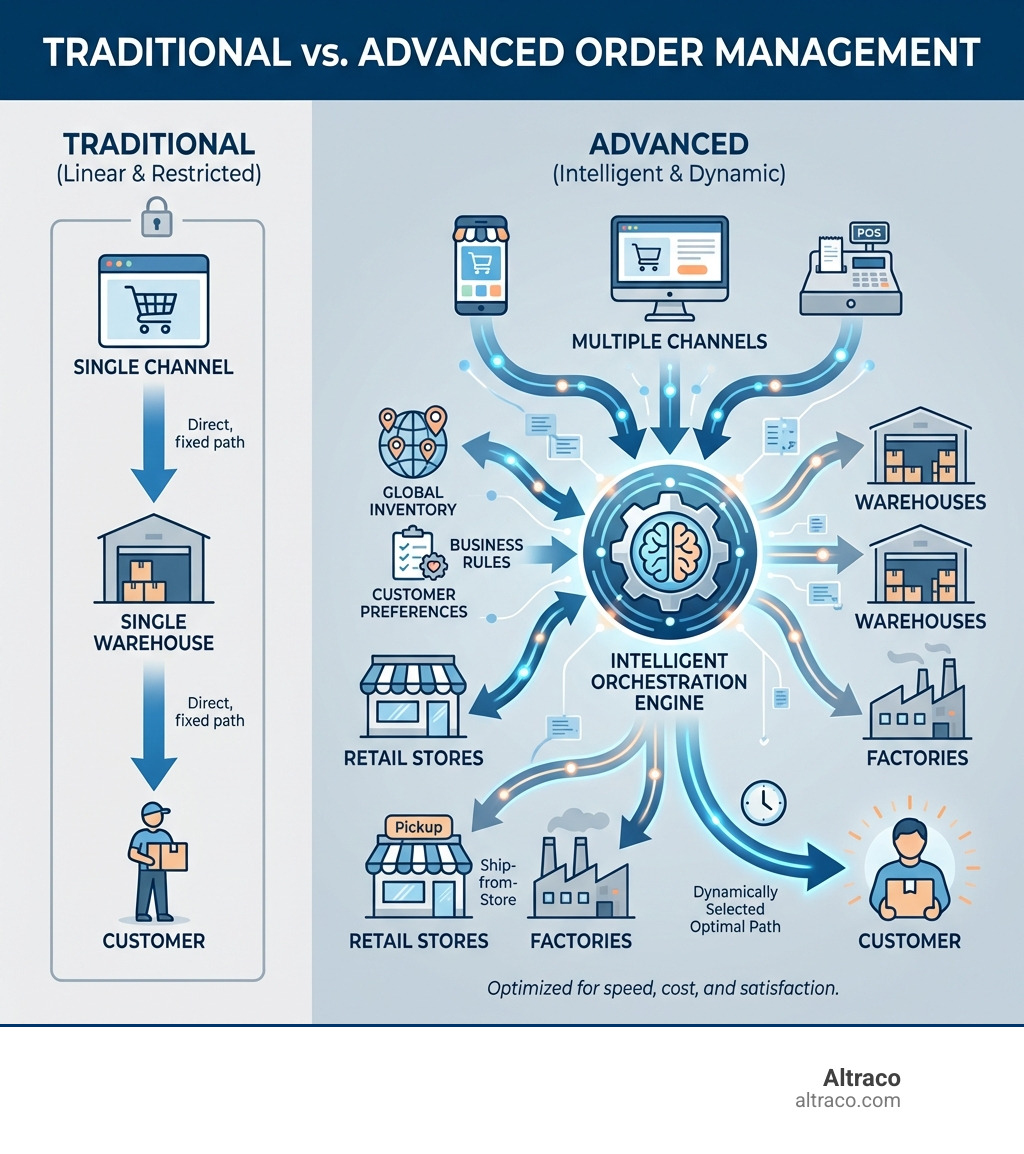

Traditional order management systems are too linear and siloed for this complexity. They lack cross-location visibility, can’t automate fulfillment decisions, and require manual exception handling that doesn’t scale.

Advanced order management adds intelligent orchestration, using business rules and real-time data for optimal, automated fulfillment decisions. The result is lower costs, faster delivery, higher customer satisfaction, and scalable operations without adding labor.

I’m Albert Brenner, and over 40 years of co-owning a contract manufacturing company, I’ve seen how advanced order management systems transform operations for Fortune 500 companies navigating global supply chains. At Altraco, we’ve integrated these principles into our approach to offshore manufacturing for home improvement, sporting goods, automotive, and outdoor products across Mexico, China, and Vietnam.

Advanced order management word roundup:

Foundations: What is Advanced Order Management?

At its heart, advanced order management (AOM) is about delivering the “perfect order” every time. It’s a sophisticated evolution of standard order management, moving from simple transaction processing to intelligent orchestration. It’s like a smart navigation system that considers real-time traffic and other factors, not just the shortest route.

AOM simplifies the order journey from placement to shipment. Unlike siloed traditional systems, it provides real-time visibility and control over orders, inventory, and shipping across all locations and sales channels.

What makes order management “advanced”?

What lifts AOM beyond the conventional is its ability to introduce intelligent decision-making and automation into the order lifecycle. It’s not just about tracking orders; it’s about optimizing them.

- Order Orchestration: AOM adds “allocation orchestration,” letting the system intelligently and automatically decide the best fulfillment location based on business rules like cost, speed, and inventory.

- Intelligent Sourcing: With global inventory visibility, AOM dynamically sources products from the optimal location—a warehouse in Long Beach, a store in Thousand Oaks, or a partner in Mexico—ensuring delivery from the most efficient point.

- Global Inventory Visibility: AOM provides a 360-degree view of all inventory, wherever it’s stored. This insight lets you leverage stock across all sites, preventing lost sales from localized stockouts.

- Exception Handling: AOM automates most orders, flagging only exceptions for human review. This “manage by exception” approach eliminates manual work and keeps labor costs fixed as you scale.

- B2B Relationship Support: For B2B clients with complex products like automotive parts, reliability is key. AOM helps ensure commitments are realistic and achievable. This builds trust by delivering on the promise of timely, functional products and services. You can learn more about how advanced systems support complex operations here.

The shift from basic to advanced order management

The rise of omnichannel retail and changing customer expectations demand a more agile approach to order fulfillment. We’ve seen a significant shift driven by:

- Rising Customer Demands: Today’s shoppers expect fast, free delivery and flexible options like home delivery, store pickup, or ship-from-store.

- Omnichannel Retail: Businesses must “save the sale by enabling omnichannel fulfillment from wherever you hold inventory,” treating every location, from a Los Angeles warehouse to a California store, as a fulfillment center.

- Globalized Supply Chains: For companies like ours, specializing in Offshore Manufacturing and Supply Chain Support in Mexico, China, and Vietnam, managing global orders is a daily reality. The complexity of sourcing, manufacturing, and distributing globally while navigating trade policies and tariffs makes AOM indispensable.

- Need for Efficiency: AOM lets us “optimize fulfillment to meet demand and increase inventory turns while preserving safety stock,” efficiently managing inventory to cut manual work and operational costs.

- Scaling Business Operations: As businesses grow, manual processes become bottlenecks. AOM provides the infrastructure to “scale your business but keep labor fixed,” enabling efficient growth without a proportional increase in headcount.

| Criteria | Standard Order Management | Advanced Order Management |

|---|---|---|

| Inventory View | Siloed (per location/channel) | Global (all locations, real-time) |

| Fulfillment Logic | Fixed (manual or simple rules) | Dynamic (intelligent, rule-based) |

| Channel Integration | Basic (limited, often separate) | Omnichannel (seamless, centralized) |

| Automation | Minimal (manual intervention common) | Extensive (exception-based management) |

| Decision Making | Reactive (after issues arise) | Proactive (optimizes before issues) |

| Flexibility | Low (rigid processes) | High (adapts to changing conditions) |

The Engine Room: Core Components and Functionalities

AOM’s core functionalities automate and optimize the order lifecycle, giving businesses unprecedented control and flexibility. They are the engine ensuring every order is handled with precision.

Order Orchestration and Centralization

The first step in taming order chaos is bringing everything under one roof. Advanced order management systems consolidate orders from diverse sources into a single, unified view.

- Consolidating Orders: AOM pulls orders from e-commerce platforms, point-of-sale (POS) systems, or phone calls into one place. This centralization eliminates disparate system headaches and prevents lost orders.

- Single Customer View: Managing orders from multiple channels provides a “360-Degree View of the Customer.” This allows for quick contract generation with all terms and details, ensuring service teams know customer entitlements at any time.

- For more on managing your crucial inventory, explore our Inventory Management Solutions.

Intelligent Inventory Allocation and Sourcing

This is where the “advanced” truly shines. AOM intelligently decides the best way to fulfill an order.

- Automatic Location Assignment (ALA): This feature automatically assigns fulfillment locations to sales orders based on business rules. The system intelligently selects the best fulfillment location using global inventory data and your business objectives, eliminating guesswork.

- Business Rules: These rules are the brains of the operation. We can configure them to prioritize:

- Cost Optimization: Shipping from the closest warehouse to reduce freight expenses.

- Delivery Speed: Fulfilling from the location that can get the product to the customer fastest.

- Proximity: Fulfilling orders for local customers from nearby stores or distribution centers.

- Safety Stock Preservation: Protecting critical inventory levels in certain locations by sourcing from others.

- Preserving Safety Stock: AOM helps “optimize fulfillment to meet demand and increase inventory turns while preserving safety stock.” This balance is crucial for high-demand products like automotive parts, ensuring we meet current demand without risking future supply.

- For those interested in the technical aspects of defining complex order logic, the principles of conditional logic in resources like Technical details on Advanced Orders illustrate the sophisticated rules AOM systems can employ.

Fulfillment Automation and Shipping

Once the optimal fulfillment location is determined, AOM automates the steps to get the product out the door.

- Fulfillment Requests: AOM automatically creates fulfillment requests for chosen locations, streamlining store pickup or ship-from-store operations and instantly notifying the right teams.

- Ship-from-Store and Store Pickup: These omnichannel strategies are fully supported. AOM improves orders for store pickup and mixed orders, generating fulfillment requests and notifying the customer when their order is ready. It also turns retail locations into mini-distribution centers to fulfill online orders.

- Automated Notifications: Automation keeps everyone in the loop, from customer order confirmations to warehouse pick lists, without manual effort.

- Shipping Label Generation: AOM integrates with shipping solutions to automatically print labels and other documents, speeding up dispatch.

- To understand how these pieces fit into the larger picture, take a look at Logistics Management Activities.

The AOM Process in Action: From Order to Delivery

The advanced order management process transforms complex decisions into a streamlined, automated workflow, ensuring a harmonious delivery.

Step 1: Order Compilation and Validation

The journey begins the moment a customer places an order.

- Aggregating Orders: AOM gathers all incoming orders—from e-commerce, phone sales, or POS—into a central hub for control.

- Validating Order Data: The system validates order data for accuracy, from customer details to product SKUs, preventing downstream errors.

- Prioritizing Orders: AOM allows for prioritization based on rules, such as flagging orders from VIP customers or those with urgent requirements for critical automotive parts.

- Future-Dated Orders: AOM can manage future-dated orders, allowing businesses to plan ahead for seasonal outdoor products or product launches.

Step 2: Allocation and Sourcing

This is the strategic heart of AOM, where the system decides how and where to fulfill an order.

- Applying Rules: Using configured business rules (e.g., cost, speed, proximity), AOM intelligently evaluates where to fulfill each order, checking inventory across California warehouses or a partner factory in Mexico.

- Selecting Fulfillment Location: The Automatic Location Assignment (ALA) feature automatically selects the best source for optimal efficiency.

- Splitting Orders: AOM can “split orders to create multiple orders from a single quote, letting you send products to multiple locations or at different times,” which is useful for large B2B orders or phased rollouts.

- Backorder Management: If an item is unavailable, AOM manages backorders, allocating stock as it arrives and keeping customers informed.

Here are some common allocation rules:

- Lowest Cost: Prioritize fulfillment from the location with the lowest shipping and handling costs.

- Fastest Delivery: Select the location that can deliver the product to the customer in the shortest time.

- Proximity: Fulfill from the closest physical location to the customer.

- Preserve Safety Stock: Avoid depleting critical inventory in key locations by sourcing from others.

Step 3: Fulfillment and Shipping

With allocation decided, AOM streamlines the physical movement of goods.

- Release for Fulfillment: Orders are systematically released to chosen fulfillment locations, giving warehouse managers control over the picking and printing process.

- Generating Pick Lists: Automated systems generate optimized pick lists to guide staff efficiently through the warehouse.

- Notifying Warehouses or Stores: Real-time notifications ensure fulfillment teams are immediately aware of new orders.

- Carrier Integration and Tracking Updates: AOM integrates with shipping carriers, automating label printing and providing customers with real-time tracking updates.

Step 4: Managing Exceptions and Returns

AOM is built to handle exceptions, turning potential problems into manageable tasks.

- Automated Exception Handling: AOM flags exceptions like inventory discrepancies or shipping delays, allowing teams to “manage only by exception” and focus human attention where it’s needed.

- Inventory Discrepancies: If a physical count doesn’t match system records, AOM can trigger alerts or automated reconciliation to prevent incorrect fulfillment.

- Shipping Delays: If a delay occurs, AOM can automatically notify customers, providing proactive communication.

- Streamlining Returns: A robust AOM system can integrate with return merchandise authorization (RMA) processes, ensuring returned goods are processed efficiently and inventory is updated. Maintaining high standards is crucial, and you can learn more about our approach to Quality Control.

Mastering Complexity in Modern Global Supply Chains

Advanced order management is a critical tool for managing the demands of international manufacturing and sourcing for products like automotive parts, sporting goods, and home improvement items. At Altraco, we understand these complexities because we steer them daily.

Facilitating Omnichannel Strategies

AOM empowers businesses to deliver on the promise of omnichannel retail, creating a seamless customer experience while optimizing internal processes.

- Buy-Online-Pickup-In-Store (BOPIS): With AOM, when a customer orders online for pickup at a California store, the system automatically generates a fulfillment request, notifies the customer, and updates inventory in real-time.

- Ship-from-Store: By turning retail locations into mini-fulfillment centers, AOM lets you leverage store inventory for online orders. This increases inventory turns and helps “save the sale by enabling omnichannel fulfillment from wherever you hold inventory.”

- Endless Aisle: AOM helps create an “endless aisle” where if a product isn’t in a store, it can be ordered from another location and shipped to the customer or store.

- Consistent Customer Experience: Centralizing order management and offering flexible options ensures a consistent, positive customer experience.

- Increased Inventory Turns: Utilizing all available inventory across your network, including retail stores, improves inventory turns and reduces warehousing costs.

Supporting Complex B2B and Global Manufacturing

For businesses in contract manufacturing and global sourcing, AOM is indispensable.

- Split Quotes into Multiple Orders: For a large client ordering automotive components, AOM can “split quotes into multiple orders, manage future dated orders,” enabling phased deliveries to different plants that align with production schedules.

- Phased Rollouts: For clients launching new sporting goods or undertaking a home improvement project, AOM manages delivery to multiple locations at different times, ensuring components arrive when needed.

- Managing Offshore Manufacturing and Supply Chain Support: As a contract manufacturing partner, we coordinate production with factories in Mexico Manufacturing, China, and Vietnam. AOM helps manage the flow of finished goods from these global sites to our clients’ distribution centers.

- Coordinating Production Across Partners: AOM facilitates seamless coordination, providing a clear view of deliveries. This is critical for our teams to “recognize revenue properly” and understand customer entitlements.

- Tariff Navigation: Global trade tariffs can impact costs. Altraco’s expertise in tariff navigation, including developments like US Supreme Court decisions, complements AOM by ensuring fulfillment strategies are efficient and compliant.

Enhancing your advanced order management with a global partner

A robust AOM system is more effective with a partner who understands the realities of Global Sourcing. This synergy helps manage international logistics, supplier coordination, and trade compliance.

At Altraco, based in Thousand Oaks, CA, we simplify global supply chains. We leverage decades of experience, trusted factory relationships across Mexico, China, and Vietnam, and tariff expertise to ensure quality, on-time products with significant cost savings. Combining our hands-on experience with your AOM system gives you an unparalleled advantage in managing global operations for home improvement, sporting goods, automotive, and outdoor products. We act as an extension of your team, ensuring your AOM system’s decisions are executed flawlessly.

Opening up Business Value: The Tangible Benefits of AOM

Implementing an AOM system delivers measurable improvements across the business. These real-world gains impact your bottom line and brand reputation.

Improved Efficiency and Cost Reduction

AOM is a master of efficiency, systematically driving down operational costs.

- Eliminating Manual Work: Automating tasks like location assignment and fulfillment requests reduces human intervention. This means less paperwork, fewer errors, and more time for strategic initiatives.

- Reducing Labor Costs: With automation, you can “scale your business but keep labor fixed.” This allows for growth without a proportional increase in operational headcount, leading to significant labor savings.

- Optimizing Shipping Costs: Intelligent allocation ensures orders are shipped from the most cost-effective location, such as a local Los Angeles warehouse or a California retail store.

- Lowering Inventory Holding Costs: By optimizing fulfillment and increasing inventory turns, AOM reduces how long inventory sits in storage, minimizing carrying costs and freeing up capital.

- Managing by Exception: Your team only needs to address orders that fall outside predefined parameters. This streamlined approach boosts productivity and reduces resources spent on routine tasks.

Increased Sales and Customer Satisfaction

Happy customers are repeat customers, and AOM helps create them.

- Saving the Sale: If a popular outdoor product is out of stock at your main warehouse, AOM can find it at a local store, letting you “save the sale by enabling omnichannel fulfillment from wherever you hold inventory.” This prevents lost revenue and keeps customers happy.

- Preventing Stockouts: A global inventory view and intelligent stock allocation minimize the chances of telling a customer an item is unavailable when it’s in your network.

- Prompt Delivery: Optimized fulfillment and automated processes help ensure “prompt delivery and giving them the fulfillment options they want,” meeting modern customer expectations.

- Flexible Fulfillment Options: Offering choices like ship-from-store or store pickup caters to diverse customer preferences, improving the purchasing experience.

- Building Brand Advocates: When customers consistently receive orders quickly and accurately, their satisfaction grows. This positive experience turns them into loyal customers and brand advocates.

Conclusion

In today’s landscape of demanding customers and complex global supply chains, advanced order management is a necessity for growth. It’s the engine that transforms chaotic order fulfillment into a streamlined, optimized process, delivering the “perfect order” every time.

By orchestrating orders, intelligently allocating inventory, automating fulfillment, and managing exceptions, AOM empowers businesses to operate with greater efficiency and precision. It allows you to satisfy omnichannel shoppers, reduce costs, and scale your operations without friction.

For businesses in global manufacturing of automotive parts, sporting goods, or home improvement gear, AOM provides the visibility and control to manage international sourcing, production in Mexico, China, and Vietnam, and trade compliance.

At Altraco, we know that mastering global operations requires a strategic approach to your entire supply chain. We combine our experience in offshore manufacturing, trusted factory relationships, and tariff navigation expertise to simplify these complexities. Explore our Integrated Supply Chain Services to see how we can simplify your global manufacturing and logistics.

Al is an entrepreneur, founder, and owner of multiple businesses, including Altraco, an outsourcing and contract manufacturing company. Working across multiple continents and trusted by Fortune 500 companies, Al finds innovative solutions to traditional supply chain challenges. He is a member of Vistage Worldwide.