Quality Control in Manufacturing

Gain confidence with inspections earlier in the supply chain.

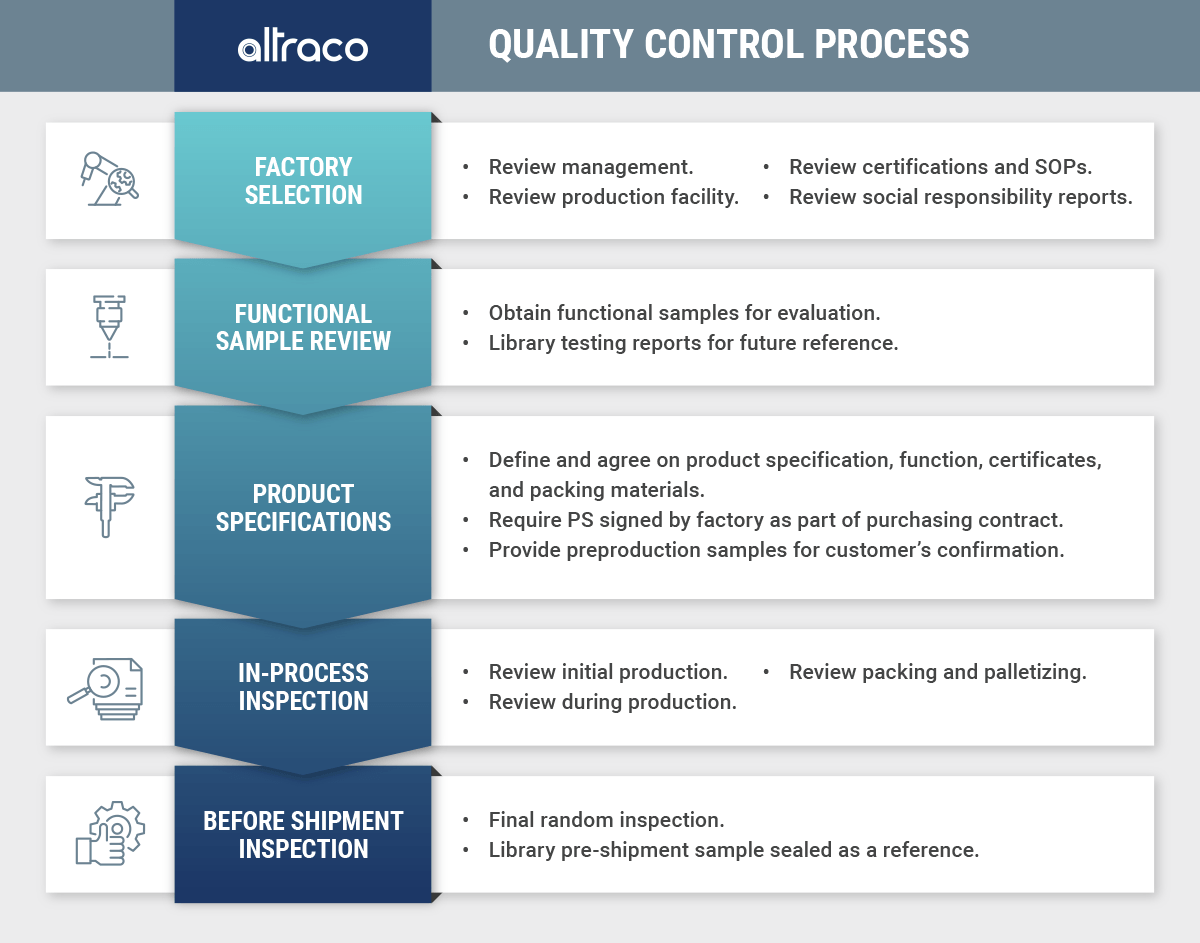

Altraco’s quality control process samples your goods in accordance with internationally accepted standards. This is done in conjunction with conducting a comprehensive quality assessment tailored to your unique product.

Don’t wait to inspect until it’s too late!

Our inspection process addresses first articles, initial production, during-production and pack & palletizing to name a few. You can rest assured that all products will meet your quality and quantity expectations delivered on time. Inspecting the goods once they arrive in the U.S. is too late!

Our List of Quality Control Checks

Our team uses comprehensive quality control checklists. Some examples include:

Workmanship

Color

Artwork

Dimensions

Quantity

Shipping Marks

Packaging

Packing

Palletizing

Function

Photos from actual manufacturing plant Altraco partners with in China

Quality control takes a team.

Production errors are typically discovered after products leave the factory. Our overseas quality team overcomes this challenge by traveling to each factory prior to full production to diligently inspect products. This means issues (if any) are found early and resolved quickly to avoid wasting materials and time. It’s better to prevent a problem than fix a problem!

CNAS Certified

Our inspection facility is certified by China National Accreditation Service for Conformity Assessment (CNAS), the national accreditation body tasked with ensuring industries provide service through impartial conduct, scientific means, and accurate results. This certification is another way to reinforce our mission to provide you quality products on-time at a compelling price.