Why Supplier Scorecards Are Essential for Modern Manufacturing

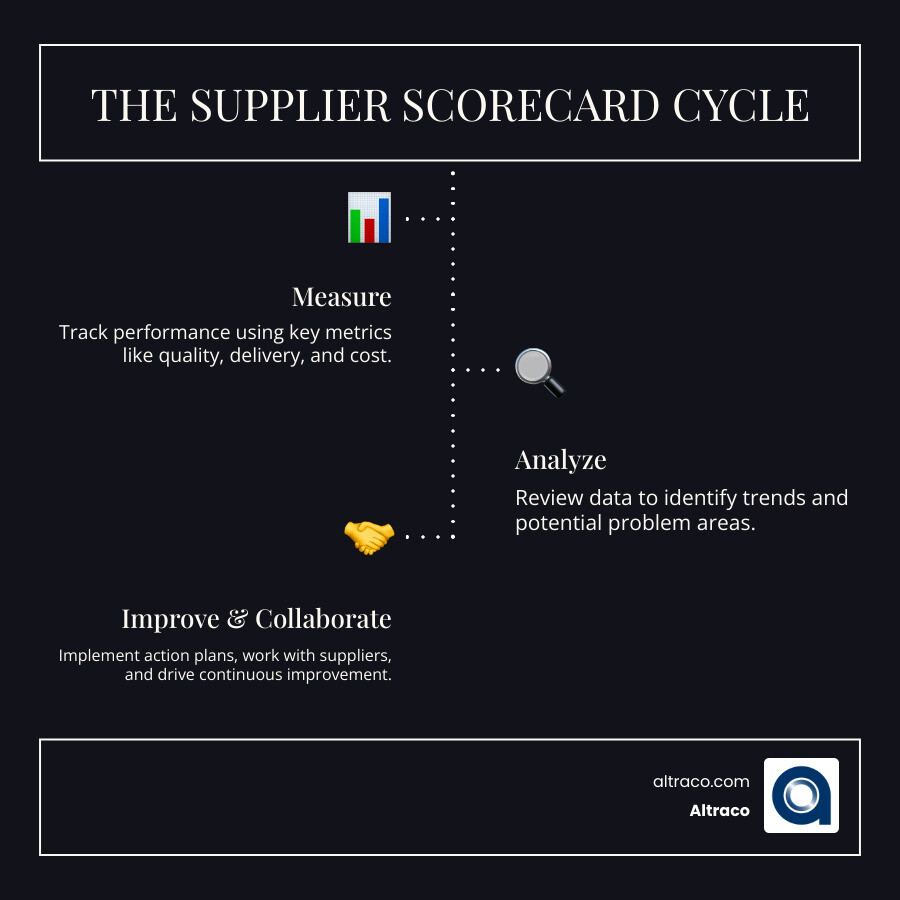

Supplier scorecards are systematic tools that measure and evaluate vendor performance against metrics like quality, delivery, cost, and service. These data-driven systems help companies make objective decisions about their supply chain partners by:

- Measuring performance with key metrics like on-time delivery and quality defects.

- Enabling objective comparison of suppliers using standardized criteria.

- Identifying risks before they disrupt production.

- Driving improvement with actionable feedback.

- Supporting decisions on contracts, sourcing, and vendor selection.

The numbers tell the story: 73% of organizations tracking supplier performance experience fewer supply chain disruptions. Effective supplier management can also reduce procurement costs by 15% and improve lead times by 20%.

This is critical when manufacturing overseas, where a lack of performance tracking can lead to overlooked vendor issues and costly production delays.

As Albert Brenner, co-owner of Altraco with over 40 years in contract manufacturing, I’ve seen how supplier scorecards transform relationships with overseas factories. For our Fortune 500 clients in home improvement, sporting goods, and automotive parts, these tools are essential for managing complex supply chains across Mexico, China, and Vietnam.

The Strategic Value and Benefits of Using Supplier Scorecards

Supplier scorecards provide clear visibility into supplier performance, replacing gut feelings with hard data. This shift drives better decision-making, leading to significant procurement cost reduction, effective supply chain risk mitigation, and improved supplier collaboration.

At Altraco, we’ve seen this change across our factory networks in Mexico, China, and Vietnam. When manufacturing automotive parts or sporting goods globally, objective data is essential. Building Strong Supplier Relationships becomes easier when expectations and performance metrics are clear. The 2023 State of Risk & Compliance Report confirms that companies prioritizing structured supplier evaluation consistently outperform those that don’t.

Key Benefits for Your Business

A structured approach to measuring supplier performance delivers tangible improvements to your bottom line and daily operations.

- Reduced procurement costs: Objective data supports negotiations, with studies showing businesses using scorecards achieve 12% cost savings through better sourcing.

- Improved lead times: Consistent delivery monitoring leads to significant gains. Organizations with structured programs see a 25% improvement in supplier timeliness.

- Fewer supply chain disruptions: As noted, 73% of organizations tracking performance experience fewer disruptions, a critical benefit for meeting launch dates.

- Improved product quality: Tracking quality metrics reduces defects and rework, protecting brand reputation. We emphasize our Proven Tips to Improve Quality in Overseas Manufacturing as part of this strategy.

- Stronger buyer-supplier partnerships: Transparency and trust grow when everyone speaks the language of performance metrics, turning vendors into true partners.

- Data-backed negotiations: Concrete performance data makes every negotiation more productive and fair for both sides.

How Scorecards Mitigate Supply Chain Risk

Scorecards act as an early warning system, helping you see problems before they become crises in your global supply chain.

- Identifying underperforming suppliers: The scorecard reveals negative patterns and trends that might be invisible in day-to-day operations.

- Monitoring financial stability: Incorporating financial health indicators helps you spot potential supplier failures before they disrupt production.

- Ensuring regulatory compliance: Scorecards can track adherence to environmental, labor, and safety regulations across different countries.

- Assessing geopolitical risks: Scorecards help evaluate a supplier’s vulnerability to global events, supporting diversification strategies.

- Proactive issue resolution: Performance trends allow you and your suppliers to address potential problems collaboratively before they impact production.

Building an Effective Scorecard: Key Components and Metrics

An effective supplier scorecard balances quantitative data (the numbers) with qualitative insights (the human observations). The best scorecards tell a clear story about supplier performance and provide a roadmap for improvement. At Altraco, we customize scoring systems and weighting criteria based on what matters most to each client, whether they’re producing automotive parts in Mexico or sporting goods in Vietnam.

Essential Components to Include

Every effective scorecard should include these core elements:

- Supplier Contact Information: Basic details about who and where the supplier is.

- Performance Categories: The big-picture areas being evaluated, such as Quality, Delivery, Cost, and Service.

- Key Performance Indicators (KPIs): The specific, measurable metrics within each category (e.g., defect rate).

- Scoring Methodology: A clear and consistent system (e.g., 1-5 scale, percentages) for fair comparison.

- Weighting Factors: Prioritizing metrics based on strategic importance. For a critical automotive part, quality might be weighted at 40%, while for a seasonal item, delivery might be paramount.

- Comments and Action Items: A space to explain the “why” behind the numbers and outline next steps for improvement.

Critical KPIs for Effective Supplier Scorecards

Choosing the right KPIs is crucial. As Suman Sarkar agrees, it’s better to focus on fewer, more meaningful metrics.

- Quality Metrics: Track defect rates, order accuracy, and compliance with specifications.

- Delivery Metrics: Monitor on-time delivery, lead times, and order completeness.

- Cost Metrics: Evaluate price competitiveness, invoice accuracy, and supplier-led cost savings initiatives.

- Service and Communication: Measure response times, proactive communication, and issue resolution speed.

- Risk and Compliance: Assess financial health, sustainability practices, and regulatory compliance.

For more ideas, Supply Chain Quarterly’s supplier scorecard guide offers additional perspective.

Customizing Scorecards for Your Industry

Tailoring scorecards to your specific industry needs is where real expertise comes in.

- Align with Business Goals: If your company prioritizes sustainability, those metrics should feature prominently. If speed-to-market is key, lead times are critical.

- Address Industry-Specific Needs: For automotive parts, we focus on precision, defect rates (parts per million), and regulatory compliance. For home improvement products, durability, aesthetics, and safety certifications are key. Sporting goods require a focus on material innovation, performance testing, and demand flexibility.

- Use Supplier Segmentation: Not all suppliers need the same level of scrutiny. Strategic suppliers (e.g., a core component factory in Vietnam) get detailed, frequent reviews. Tactical and transactional suppliers receive less frequent, simpler scorecards. This approach is recognized by industry giants; for example, sustainability is now an important supplier criterion for P&G.

A Step-by-Step Guide to Implementation and Best Practices

Implementing supplier scorecards is a process of continuous improvement. At Altraco, we’ve guided countless clients through this journey, establishing reliable manufacturing partnerships across Mexico, China, and Vietnam. The key is taking it step by step.

How to Create and Implement a Scorecard

- Involve Stakeholders: Bring together teams from procurement, quality, operations, and engineering. As Suman Sarkar agrees, this cross-functional input is essential.

- Define Clear, Measurable KPIs: Start with 2-3 critical metrics that are specific, measurable, and relevant. Think “Reduce defect rate by 15% in Q3” instead of “improve quality.”

- Gather Accurate Data: Pull information from ERP systems, quality reports, and delivery logs. Cross-reference multiple sources to ensure accuracy.

- Start Small and Simple: Pilot your scorecard with a few key suppliers. You can expand the program as you learn what works.

- Maintain Open Communication: Share your methodology with suppliers upfront. This transparency builds a collaborative partnership focused on mutual success.

Best Practices for Ongoing Management

Once scorecards are running, consistent management is key.

- Schedule Regular Reviews: Hold quarterly reviews for critical partners and semi-annual or annual reviews for others. Consistency is crucial.

- Foster a Collaborative Process: Use reviews for joint problem-solving, not pointing fingers. Discuss results, align expectations, and develop action plans together.

- Provide Actionable Feedback: Go beyond scores. Dig into the “why” behind performance issues and suggest specific, constructive solutions.

- Use Scorecards to Drive Improvement: Celebrate wins and work together on challenges. As insights from SourceDay show, shared data fosters trust and long-term success.

Common Challenges and How to Overcome Them

- Supplier Resistance: Overcome this by framing scorecards as tools for shared success and a stronger business relationship.

- Inaccurate Data: Address this with standardized data collection processes and leveraging technology to automate and integrate information.

- Lack of Internal Buy-in: Get all stakeholders involved from the beginning to create ownership and ensure the initiative’s long-term success.

- Overly Complex Systems: Start with a few critical KPIs and add complexity gradually. A simple, consistently used scorecard is better than a complex one that’s ignored.

- Ensuring Objectivity: Use clear, data-driven criteria and involve multiple internal perspectives to maintain fairness and remove bias.

The Future of Scorecarding: Automation and AI

The world of supplier scorecards is rapidly evolving from manual spreadsheets to smart, dynamic systems. At Altraco, we see these advances changing how we manage factory partnerships in Mexico, China, and Vietnam, moving from periodic check-ups to real-time supply chain health monitoring.

Manual vs. Automated Supplier Scorecards

The difference is like comparing a horse-drawn carriage to a modern car. Automation makes the journey smoother, faster, and more reliable.

| Feature | Manual Supplier Scorecards | Automated Supplier Scorecards |

|---|---|---|

| Data Collection | Time-consuming, manual entry, prone to human error | Automated integration with ERPs, quality systems, IoT sensors |

| Accuracy | Dependent on manual input, potential for inconsistencies | High, real-time data, reduced errors |

| Scalability | Difficult to manage for many suppliers/KPIs | Easily scales to hundreds of suppliers and complex metrics |

| Reporting | Static reports, delayed insights | Dynamic dashboards, real-time analytics, customizable reports |

| Alerts | Manual monitoring, reactive | Proactive, automated alerts for performance deviations |

| Collaboration | Email-based, can be disjointed | Centralized portals, direct communication channels |

| Cost | Lower initial software cost, higher labor cost | Higher initial software cost, significantly lower labor cost |

| Insight | Basic performance overview | Predictive analytics, root cause analysis, strategic insights |

How Automation Improves Effectiveness

Automated supplier scorecards provide instant visibility into global manufacturing operations.

- Real-Time Data Integration: Direct connections to ERP, quality, and production systems mean we know immediately when a shipment leaves a factory in Vietnam or a quality issue arises in China.

- Automated Alerts: This early warning system notifies us the moment a delivery falls behind schedule or defect rates climb, allowing for proactive problem-solving.

- Dynamic Performance Dashboards: Interactive visuals replace static reports, highlighting trends and allowing deep dives into data to spot patterns.

- Reduced Administrative Burden: Automation can cut scorecard management time by over 60%, freeing teams to focus on strategic relationship-building.

- Centralized Communication Portals: Suppliers can log in to see their scores and communicate directly, strengthening transparency and partnership.

Leveraging AI and Machine Learning in Scorecarding

AI and machine learning are open uping unprecedented insights.

- Predictive Analytics for Risk Forecasting: AI analyzes vast data sets (performance history, market trends, geopolitical events) to predict potential supply chain disruptions.

- Anomaly Detection in Performance: Machine learning algorithms spot subtle, negative patterns in performance data that a human might miss.

- Automated Performance Evaluations: AI can handle routine scoring and initial analysis, freeing teams to focus on interpretation and strategic action.

- AI-Driven Recommendations: The system can suggest solutions, such as alternative shipping routes or process improvements based on best practices.

For companies manufacturing complex products overseas, these AI-powered insights are becoming essential. At Altraco, we explore these technologies to help us Maintain Quality Control Program standards and drive efficiency.

Frequently Asked Questions about Supplier Scorecards

Over our years helping companies manage overseas manufacturing, we’ve fielded countless questions about supplier scorecards. Here are the most common ones.

What is the primary purpose of a supplier scorecard?

The primary purpose is to objectively measure, evaluate, and manage supplier performance against predefined metrics. This data-driven approach enables better procurement decisions, mitigates supply chain risks, and drives continuous improvement. For a supplier in Mexico producing automotive parts or a factory in China making sporting goods, the scorecard provides a clear, data-backed view of performance.

How often should supplier performance be reviewed using a scorecard?

The frequency depends on the supplier’s strategic importance.

- Critical or strategic suppliers: Quarterly reviews are ideal, supplemented by a comprehensive annual review.

- Less critical or transactional suppliers: Semi-annual or annual reviews are often sufficient.

The key is to establish a consistent, predictable cadence that both you and your suppliers in Vietnam, China, or Mexico can plan for.

How can scorecards be used to improve supplier relationships?

Scorecards improve relationships by creating a transparent, data-driven foundation for communication. They shift conversations from subjective complaints to collaborative problem-solving based on objective data that both parties can see. When we review performance with our factory partners and develop action plans together, trust builds. This process clarifies expectations upfront and transforms vendors into partners invested in your success.

Conclusion

In today’s global manufacturing landscape, success hinges on building strong supplier relationships that deliver quality, reliability, and continuous improvement. Supplier scorecards are the essential tool for managing these partnerships, especially when working with factories thousands of miles away.

As we’ve explored, structured supplier evaluation leads to fewer disruptions, lower costs, and better delivery performance. For companies manufacturing home improvement, sporting goods, or automotive parts overseas, a robust scorecard system is not optional—it’s vital for navigating complexity and mitigating risk.

The future lies in automated systems and AI-driven insights, but the core principle remains: you can’t manage what you don’t measure. Scorecards provide that framework, creating the transparency and accountability needed for true partnership.

At Altraco, we help clients implement these systems to manage their global manufacturing relationships in Mexico, China, Vietnam, and beyond. We bridge the gaps of distance and culture to build collaborative, high-performing supply chains.

Ready to take control of your global manufacturing partnerships? Learn more about Altraco’s approach to Supplier Scorecards and find how we can build a system that works for you.