Introduction: Why Supply Chain Cost Efficiency is a Strategic Imperative

Cost reduction in supply chain management is no longer just a procurement exercise—it’s a strategic imperative that can determine your company’s competitive position and profitability. With supply chain expenses representing 50% to 75% of the cost of doing business for most companies, even modest improvements can open up millions in savings and free up capital for growth and innovation.

Quick Answer: How to Reduce Supply Chain Costs

The most effective cost reduction in supply chain management strategies include:

- Optimize inventory management – Use data-driven forecasting and safety stock calculations to reduce the $1.7 trillion annual cost of inventory distortion

- Leverage strategic sourcing – Partner with offshore manufacturers in Mexico, Vietnam, or China to access lower costs while navigating tariff complexities

- Automate operations – Deploy AI, robotics, and analytics to achieve 10-20% reductions in warehousing and distribution costs

- Build supplier partnerships – Strengthen communication and collaboration to reduce variability and transportation expenses (US businesses spent $2.6 trillion on shipping in 2023)

- Create a cost-aware culture – Companies that align culture with cost goals achieve up to 11% greater long-term savings

The reality is stark: inflation, tariff uncertainty, and rising transportation costs are squeezing margins. Global shipping disruptions continue to create volatility that threatens both costs and service levels.

But here’s the good news: you don’t have to sacrifice efficiency or quality to reduce costs. The most successful companies approach supply chain optimization strategically—using data transparency, technology, and trusted manufacturing partners to build leaner operations that actually improve service levels while cutting expenses.

This challenge is particularly acute for large enterprises managing complex global supply chains. Coordinating offshore manufacturing, ensuring quality control across borders, navigating shifting trade policies, and maintaining on-time delivery requires expertise and established relationships that most companies don’t have in-house.

I’m Albert Brenner, and over 40 years of helping Fortune 500 companies with contract manufacturing, I’ve seen how the right approach to cost reduction in supply chain management can transform operations and drive sustainable growth. At Altraco, we’ve built proven factory relationships across Mexico, China, Vietnam, and other key manufacturing countries specifically to help companies like yours achieve significant savings without compromising quality or reliability.

Important cost reduction in supply chain management terms:

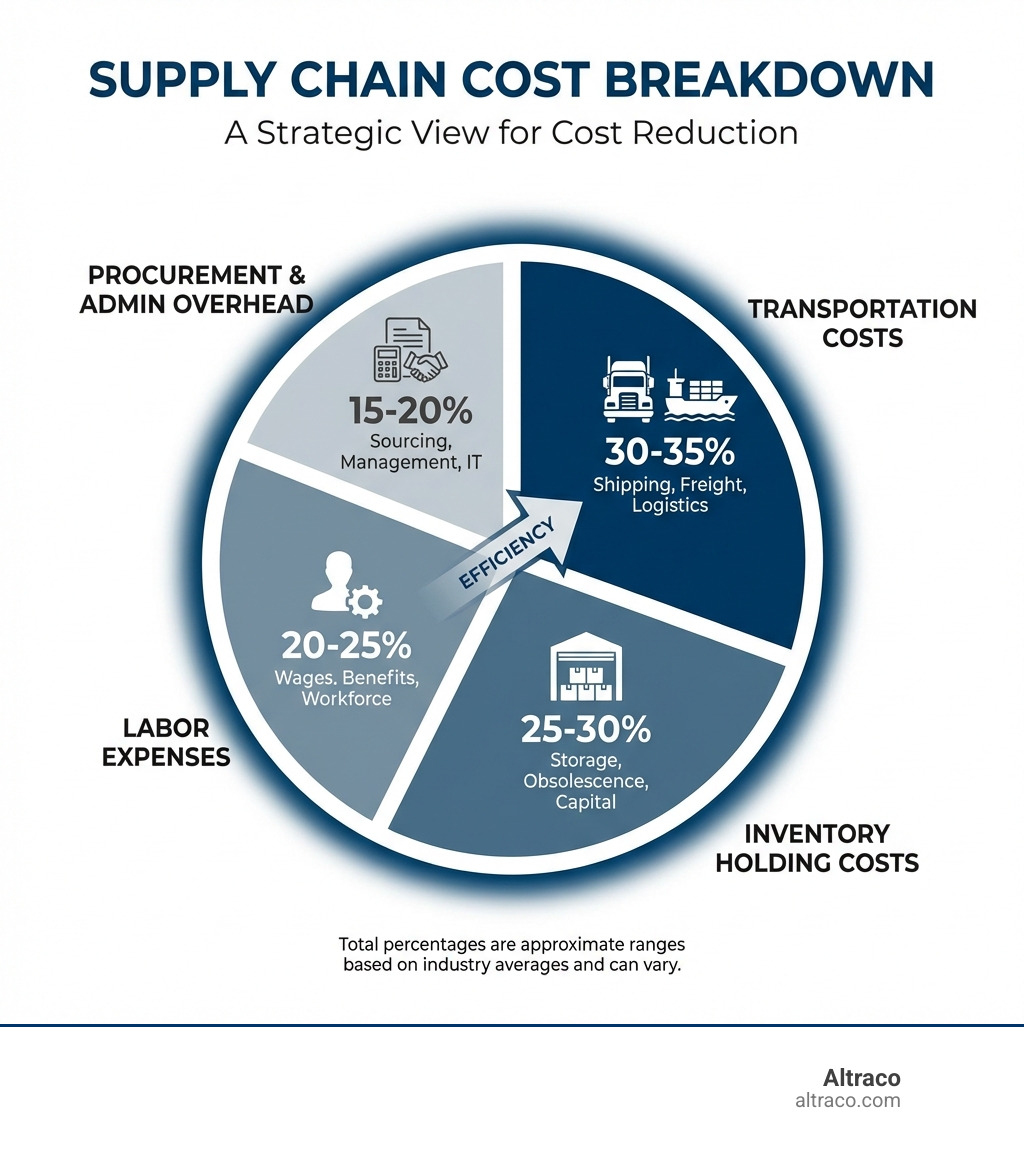

Identifying the Biggest Supply Chain Cost Drivers

Before cutting costs, we must understand what drives them. For businesses that make or move physical products, supply chain costs represent 50% to 75% of the cost of doing business. Even small inefficiencies can quickly snowball into massive expenses.

What are these culprits that drain our budgets? They’re often hiding in plain sight:

- Procurement Costs: This isn’t just the price paid for raw materials. It includes supplier selection, negotiation, contract management, and quality assurance. Inflation directly impacts these costs, especially for raw materials and components.

- Inventory Management: Holding too much of the wrong inventory, or simply mismanaging what we have, leads to significant costs. Industry studies reveal that inventory distortion costs upwards of $1.7 trillion a year. This includes expenses for storage, insurance, obsolescence, damage, and the capital tied up in stock that isn’t moving.

- Transportation and Logistics: Moving goods is complex and expensive. US businesses spent nearly $2.6 trillion on shipping-related expenses in 2023. Factors like rising fuel prices, global shipping challenges, and disruptions in major routes (like the Red Sea or Suez Canal) can cause costs to surge, as research from the United Nations shows.

- Labor Expenses: From warehouse staff and truck drivers to procurement specialists and supply chain analysts, people are essential to our operations. Labor costs include wages, benefits, training, and the cost of inefficient processes that require more human intervention than necessary.

- Administrative Overhead: This covers the costs associated with managing the supply chain—software licenses, administrative staff, compliance, and regulatory adherence.

- Inaccurate Demand Forecasts: When our predictions for customer demand are off, it creates a ripple effect. Over-ordering leads to excess inventory and its associated costs, while under-ordering can result in lost sales and rush orders. Inaccurate forecasts contribute significantly to the $1.7 trillion annual cost of inventory distortion.

- Supplier Variability: Unreliable or long lead times from suppliers can cause delays, stockouts, and the need for expedited shipping, all of which add to our operational costs. This highlights the importance of strong supplier relationships and clear communication.

- Improperly Regulated Product Policies: Not having clear guidelines for product specifications, quality control, or returns can lead to waste, rework, and customer dissatisfaction, all impacting the bottom line.

Understanding these primary cost drivers is the first step toward implementing effective cost reduction in supply chain management. It allows us to pinpoint the areas where our efforts will yield the greatest return.

A Strategic Framework for Cost Reduction in Supply Chain Management

Effective cost reduction in supply chain management requires a strategic framework aligned with business goals. The focus should be on smart savings, not just cheap cuts.

Our approach at Altraco emphasizes three core pillars: aligning our cost agenda with our growth outlook, fostering a continuous improvement and cost-aware culture, and balancing agility and resilience. This holistic view ensures that cost savings contribute to long-term success, rather than just short-term relief.

Aligning Cost Strategies with Your Business Growth Outlook

Cost reduction in supply chain management isn’t one-size-fits-all. Strategies must be customized to a company’s growth outlook, as companies in different phases approach cost savings differently.

For instance, a company in a lower-growth, lower-margin industry might focus on consolidating its footprint, closing underperforming plants, and streamlining distribution networks. We might take a portfolio approach to cost projects, ranking them by ROI and staggering their implementation to ensure maximum impact.

Conversely, if we’re in growth mode, our cost savings might be strategically reallocated towards innovation, new product development (like home improvement, sporting goods, automotive parts, or outdoor products), or expanding into new markets. The goal is to free up capital to fuel expansion and competitive advantage. We might also dig into make-versus-buy decisions, evaluating whether producing certain components ourselves or outsourcing them to a trusted contract manufacturer like Altraco makes more financial sense. Our expertise in developing a global production strategy can be invaluable here.

Building a Continuous Improvement and Cost-Aware Culture

Strategy and technology are ineffective without the right culture. Companies that embed a cost-aware culture achieve significant benefits, with research showing up to 11% greater long-term cost reduction. Additionally, 62% of ‘cost pioneers’ report positive impacts from embedding cost consciousness into their company’s DNA.

Fostering this culture is about empowering employees to identify efficiencies. Key steps include:

- Make a Clear Case for Change: Explain why cost reduction in supply chain management is important and how it contributes to the company’s overall success.

- Communicate Consistently: Use town halls, team huddles, and internal newsletters to keep everyone informed about cost goals and progress.

- Set Clear Metrics and KPIs: Give teams measurable targets and track performance transparently.

- Empower Employees: Encourage ground-up innovation. Often, the people on the front lines have the best ideas for improving processes.

- Accept Lean Methodologies: Tools like Six Sigma in Supply Chain Management can help instill a mindset of continuous improvement.

- Celebrate Successes: Recognize and reward individuals and teams who contribute to cost-saving initiatives.

When everyone understands their role in cost reduction in supply chain management, it transforms from a top-down mandate to a shared mission.

Balancing Agility, Resilience, and Cost Reduction

Recent global disruptions have shown that lean, cost-optimized supply chains can be brittle. The new imperative is balancing cost reduction with agility and resilience, building a supply chain that can withstand shocks and adapt quickly without breaking the bank.

This balance is particularly important for companies manufacturing abroad. For example, if we’re manufacturing automotive parts or sporting goods overseas, we need to consider how to maintain supply even if a factory experiences a shutdown or a shipping route is disrupted.

Key strategies include:

- Building Stronger Crisis Response Capabilities: Having clear plans in place for unforeseen events, whether it’s a natural disaster or a sudden geopolitical shift.

- Creating Strategic Redundancies: Dual sourcing, where we work with two suppliers for critical components, or maintaining buffer inventories of essential items, can prevent costly shutdowns.

- Comprehensive Scenario Planning: We run simulations to understand how different disruptions (e.g., demand spikes, supply decreases, new tariffs) would impact our costs and operations, allowing us to proactively mitigate risks.

- Considering Near-shoring and Regional Partnerships: For many US-based companies, manufacturing in Mexico offers significant benefits in terms of reduced lead times, lower transportation costs, and greater supply chain control. This strategy reduces reliance on vulnerable global routes and can be a powerful tool for both cost reduction and resilience. Our expertise in Mexico Manufacturing Is Changing Global Supply Chains provides a great example of this.

The goal is to create a supply chain that is not only cost-efficient but also robust enough to ensure uninterrupted supply and service, even when the unexpected happens.

Tactical Optimization: Cutting Costs in Key Operational Areas

Once the strategic framework is in place, we can dive into the tactical adjustments that yield tangible savings across our supply chain. This involves optimizing individual components, from how we manage inventory to how we choose our shipping routes.

Mastering Inventory Management to Control Costs

Inventory is often the largest asset on a company’s balance sheet, and its mismanagement can be a huge drain on profitability. As we’ve seen, inventory distortion costs upwards of $1.7 trillion annually. Effective inventory management is therefore critical for cost reduction in supply chain management.

Our strategies focus on precision and data-driven decisions:

- Accurate Demand Forecasting: This is the bedrock of good inventory management. We leverage advanced analytics and AI-powered tools to predict demand down to the SKU level, incorporating external data to improve accuracy. This helps us avoid both costly overstocking and missed sales due to stockouts.

- Data-Driven Safety Stock: We calculate safety stock levels based on real data, including demand variability, lead times, and desired service levels for each individual SKU. This minimizes the capital tied up in buffer inventory while ensuring we can meet unexpected demand.

- Inventory Segmentation (ABC Analysis): We segment our inventory into categories (e.g., A, B, C items) based on value, volume, and criticality. This allows us to apply different control strategies: tighter monitoring for high-value ‘A’ items (like specialized automotive components) and more relaxed controls for lower-value ‘C’ items.

- Reducing Obsolete Stock: AI can help predict when an item is nearing the end of its life cycle, allowing us to take proactive steps to liquidate stock before it becomes obsolete. This is crucial for industries with rapidly evolving product lines, such as outdoor products or home improvement gadgets.

- Leveraging Supplier Scorecards: We use comprehensive Supplier Scorecards for better planning to monitor supplier performance, track lead times, and identify any variability that could impact our inventory levels.

Optimizing Shipping and Transportation Expenses

With US businesses spending nearly $2.6 trillion on shipping-related expenses in 2023, this area presents enormous opportunities for cost reduction in supply chain management. Transportation costs are a major component of logistics, and even small improvements can lead to significant savings.

Here’s how we optimize these expenses:

- Shipment Consolidation: We consolidate small shipments into larger, more efficient loads. This reduces the number of trips and often qualifies for better freight rates.

- Route Optimization: Using advanced software, we analyze shipping routes to find the most efficient paths, considering factors like traffic, fuel costs, and delivery windows. AI can also help plot optimal delivery routes, reducing fuel consumption.

- Mode Selection: We choose the most appropriate transportation mode (e.g., ocean freight, rail, truck, air) based on cost, speed, and the nature of the goods. For offshore manufacturing, ocean freight is often the most cost-effective for large volumes.

- Reducing Packaging Waste: Minimizing excess packaging not only reduces material costs but also lowers shipping weight and volume, leading to lower freight charges.

- Zone Skipping: For high-volume shipments, we might bypass intermediate distribution centers and ship directly to a hub closer to the final destination, saving on final-mile delivery costs.

- Outsourcing to 3PLs: For many companies, outsourcing shipping to third-party logistics (3PL) providers can be more cost-effective, leveraging their economies of scale and expertise. Our expertise in logistics management activities can help clients steer these decisions.

Strengthening Supplier Relationships for Improved Value

Suppliers are critical partners, not just vendors. Strong, collaborative relationships are essential for effective cost reduction in supply chain management.

- Strategic Partnerships: We move beyond transactional relationships to build long-term, strategic partnerships with key suppliers. This fosters trust and encourages open communication, leading to better pricing and improved quality.

- Collaborative Planning: By sharing demand forecasts and production plans with our suppliers, we enable them to better anticipate our needs, leading to smoother operations, reduced lead times, and fewer expedited orders.

- Open Communication: Regular discussions and clear expectations are vital. We work together to identify opportunities for mutual cost savings, whether through process improvements or optimized delivery schedules. Our experience in the value of buyer-supplier relationships has shown us that this is a cornerstone of successful offshore manufacturing.

- Negotiation Strategies: We focus on total cost of ownership, not just price. This includes factors like quality, lead times, and payment terms. We continuously review vendors and commercial terms to achieve greater scale or secure material-price concessions.

- Performance Monitoring: We consistently monitor supplier performance using agreed-upon KPIs, ensuring they meet our standards for quality, delivery, and cost. This helps us identify and address issues proactively.

Leveraging Technology and Automation for Sustainable Savings

In today’s complex global landscape, technology is not just an enabler; it’s a game-changer for cost reduction in supply chain management. From automating repetitive tasks to providing predictive insights, cutting-edge tools are changing how we manage our supply chains.

The Role of Automation in Streamlining Operations

Automation is revolutionizing warehousing and logistics, freeing up human potential and significantly reducing operational costs. Nearly 40% of warehouse workers surveyed were already using some form of robotics and automation, indicating its growing adoption.

- Robotics in Warehousing: Automated Guided Vehicles (AGVs) and robotic picking systems can handle repetitive tasks like moving goods, sorting, and picking items. This reduces labor costs, increases speed, and minimizes errors.

- RFID for Inventory Tracking: Radio-Frequency Identification (RFID) tags allow for real-time tracking of inventory, providing unparalleled accuracy and visibility. This reduces time spent searching for items and helps us quickly identify discrepancies.

- Automated Order Processing: Streamlining the order-to-cash cycle through automation reduces administrative overhead, speeds up fulfillment, and minimizes manual data entry errors.

- Reducing Manual Errors: Automated systems are less prone to human error, leading to fewer mis-shipments, incorrect inventory counts, and costly rework.

- Freeing Up Skilled Labor: By automating mundane tasks, we free up employees for higher-value activities like strategic planning and problem-solving. This not only saves money but also improves job satisfaction.

Our contract manufacturing services often integrate these automated processes to ensure efficient production and logistics for our clients.

Using Data and AI for Cost Reduction in Supply Chain Management

Artificial Intelligence (AI) and data analytics are powerful tools for cost reduction in supply chain management, providing previously impossible insights for smarter, proactive decisions. The impact is significant: 19% of companies surveyed cited AI as the most important tool to reduce supply chain costs, leading to 10% to 20% reduction in manufacturing, warehousing, and distribution costs.

- Predictive Analytics: By analyzing historical data, AI can predict future trends, from demand fluctuations to equipment failures. This allows us to anticipate problems and take corrective action before they become costly.

- AI-Powered Demand Forecasting: AI can process vast amounts of internal and external data (weather patterns, social media trends, economic indicators) to provide highly accurate, SKU-level demand predictions. This directly addresses inventory distortion and helps us avoid rising business costs, as discussed in Forbes.

- Route Optimization Algorithms: AI can continuously analyze real-time traffic, weather, and delivery schedules to optimize transportation routes, reducing fuel consumption and labor costs.

- Predictive Maintenance: For manufacturing equipment (especially for automotive parts or home improvement tools), AI can predict when machinery is likely to break down, allowing for scheduled maintenance rather than costly, disruptive emergency repairs.

- Identifying Hidden Inefficiencies: AI can sift through operational data to uncover bottlenecks, waste, and inefficiencies that human analysis might miss, guiding us toward targeted improvements.

Key Performance Indicators (KPIs) to Monitor Cost-Effectiveness

To achieve sustainable cost reduction in supply chain management, we must continuously monitor performance against key metrics. These KPIs provide a dashboard to track success and identify areas for adjustment.

Here are some essential supply chain KPIs we monitor:

- Inventory Turnover Ratio: Measures how many times inventory is sold or used over a period. A higher ratio generally indicates efficient inventory management.

- Cost of Goods Sold (COGS): The direct cost attributable to the production of the goods sold. Monitoring COGS helps us understand the impact of manufacturing efficiencies.

- Order Fulfillment Cycle Time: The total time from when a customer places an order until they receive it. Shorter cycle times often correlate with lower inventory holding costs.

- Transportation Cost per Unit: This KPI tracks the cost of moving each unit of product, crucial for identifying logistics inefficiencies.

- Order Accuracy Rate: The percentage of orders delivered without errors. High accuracy reduces return costs and rework.

- Warehouse Cost per Unit: Measures the cost of storing and handling each unit in the warehouse.

- Supplier On-Time Delivery Rate: Crucial for managing lead times and ensuring consistent supply.

By regularly tracking these KPIs, often integrated into a Balanced Scorecard for Supply Chain, we gain the data-driven insights needed to make informed decisions and drive continuous improvement.

Navigating Global Sourcing and Tariffs for a Competitive Edge

For businesses in home improvement, sporting goods, and automotive parts, global sourcing is a key strategy for cost reduction in supply chain management. This landscape is complex, with tariffs and geopolitical shifts. Altraco’s expertise helps clients steer these challenges to gain a competitive edge.

Using Offshore Manufacturing to Mitigate Costs

Offshore manufacturing offers compelling opportunities for cost savings through access to lower labor costs and economies of scale. Strategically, it can significantly reduce unit production costs without sacrificing quality.

- Accessing Lower Labor Costs: Countries like Mexico, Vietnam, and China offer significantly lower labor costs compared to the United States. This can lead to substantial savings, especially for labor-intensive products. Understanding the Cost to Manufacture in Mexico is a crucial first step for many of our clients.

- Economies of Scale: Offshore factories often have the capacity and infrastructure to produce at very high volumes, allowing for greater economies of scale in raw material purchasing and production.

- Strategic Sourcing from Key Regions: We specialize in managing relationships with trusted factories in key manufacturing hubs. Our Vietnam Manufacturing Complete Guide provides insights into that region, and we also guide clients on how to partner with Chinese manufacturers effectively. This diversification helps mitigate risks associated with relying on a single region.

- Contract Manufacturing: Using contract manufacturing allows clients to leverage our established factory relationships and expertise without the overhead of owning overseas facilities. This is a core Altraco service that simplifies global supply chains.

A Proactive Approach to Tariff Navigation

Tariffs can quickly erode the cost savings achieved through offshore manufacturing. A proactive and informed approach to tariff navigation is essential for sustainable cost reduction in supply chain management.

- Understanding Tariff Impact: We help our clients understand the specific tariffs that apply to their products and origin countries, including complex regulations like Section 301 Tariffs. Our Manufacturers Guide to United States Tariffs provides a comprehensive overview.

- Strategic Sourcing to Avoid Duties: One of the most effective ways to mitigate tariff costs is through strategic sourcing. This might involve shifting production to countries not subject to specific tariffs (e.g., moving production from China to Mexico or Vietnam).

- Optimizing Product Classification: Correctly classifying products under the Harmonized Tariff Schedule (HTS) is crucial. Misclassification can lead to overpayment of duties or penalties.

- Leveraging Free Trade Agreements: We assist clients in understanding and utilizing free trade agreements (such as USMCA for Mexico) to reduce or eliminate duties on goods.

- Trade Compliance: Ensuring full compliance with all import/export regulations and customs declarations is paramount. Non-compliance can result in costly delays and fines. We help our clients understand the Pros and Cons of Tariffs and steer the complexities.

By proactively addressing tariffs and leveraging strategic offshore manufacturing, we help our clients maintain a competitive edge and achieve significant cost reduction in supply chain management.

Conclusion: Building a Leaner, More Resilient Supply Chain

Cost reduction in supply chain management is a continuous journey, not a one-time fix. It requires a strategic mindset, a culture of continuous improvement, and the intelligent application of data and technology.

By focusing on accurate demand forecasting, optimizing inventory, streamlining shipping, fostering strong supplier relationships, and leveraging automation and AI, businesses can achieve significant savings without compromising service levels. Strategic offshore manufacturing in regions like Mexico, Vietnam, and China, combined with expert tariff navigation, offers powerful ways to reduce costs and improve supply chain resilience.

At Altraco, we understand these challenges intimately. With decades of experience in contract and private label manufacturing for clients ranging from home improvement to automotive parts, we are built to simplify global supply chains. We bring you trusted factory relationships, tariff navigation expertise, and a commitment to delivering quality, on-time products with significant cost savings. Partnering with us can transform your supply chain into a lean, agile, and cost-effective engine for growth.

Ready to open up significant savings and build a more resilient supply chain? Let us be your strategic partner. Explore Altraco’s Integrated Supply Chain Services today.

Al is an entrepreneur, founder, and owner of multiple businesses, including Altraco, an outsourcing and contract manufacturing company. Working across multiple continents and trusted by Fortune 500 companies, Al finds innovative solutions to traditional supply chain challenges. He is a member of Vistage Worldwide.