An original equipment manufacturer (OEM) produces parts or products used in another company’s finished goods, which are then sold under the purchasing company’s brand. This relationship is the backbone of modern manufacturing, enabling specialized companies to create everything from automotive brake systems to smartphone processors for major brands.

Key OEM Characteristics:

- Business Model: Manufacture components for other companies to integrate into final products

- Market Focus: Primarily business-to-business (B2B) sales rather than direct consumer sales

- Specialization: Deep expertise in specific components or manufacturing processes

- Brand Relationship: Products sold under the purchasing company’s name, not the OEM’s

- Quality Standards: Must meet strict specifications set by the brand owner

The manufacturing world is a complex network of OEMs, Original Design Manufacturers (ODMs), Value-Added Resellers (VARs), and aftermarket suppliers. For instance, over 80% of vehicles in North America contain OEM parts, highlighting the importance of these partnerships.

For companies navigating offshore manufacturing, understanding these distinctions is essential for evaluating suppliers, managing costs, and ensuring quality control across global supply chains.

As Albert Brenner, co-owner of a contract manufacturer with over 40 years of experience, I’ve worked directly with original equipment manufacturer relationships to help Fortune 500 companies source quality components for home improvement, sporting goods, automotive, and outdoor products. My experience spans the evolution of global manufacturing partnerships and the critical role OEMs play in delivering cost-effective, reliable production solutions.

What is an Original Equipment Manufacturer (OEM)?

The smartphone in your hand is a product of dozens of companies. The processor, camera sensors, and battery likely come from different specialized manufacturers. These behind-the-scenes companies are original equipment manufacturers – the unsung heroes of modern manufacturing.

An original equipment manufacturer (OEM) produces components or complete products that another business integrates into their final product, which is sold under the purchasing company’s brand. This specialization is fundamental to modern manufacturing.

This relationship is fundamentally business-to-business (B2B). OEMs rarely interact with everyday consumers. Instead, they focus on perfecting their craft – whether that’s manufacturing precision brake components, developing cutting-edge processors, or creating durable outdoor equipment parts. This laser focus allows them to become true experts in their field.

Think about a major automotive brand. They don’t manufacture every bolt and wire in their vehicles. That would be incredibly inefficient. Instead, they partner with specialized OEMs who have perfected brake systems, electrical components, or engine parts. Each original equipment manufacturer brings unique expertise to the table, creating a collaborative ecosystem where everyone does what they do best.

What makes this relationship particularly interesting is that OEMs often own the intellectual property for their components. They’re not just following someone else’s blueprint – they’re the ones creating the innovative designs and engineering solutions. This ownership of design and manufacturing expertise is what separates a true OEM from a simple contract manufacturer.

Having worked with Fortune 500 companies for over four decades, I’ve seen how these partnerships can make or break a product’s success. The right original equipment manufacturer doesn’t just provide parts – they become a strategic partner in creating exceptional products that perform reliably in the field.

What Is an Original Equipment Manufacturer (OEM)?

Key Characteristics of OEM Products

OEM products are custom-built to exact specifications rather than being generic, off-the-shelf parts. They are precision-engineered solutions designed for specific applications.

Hardware components from OEMs are the gold standard, built to demanding specifications. Whether it’s a specialized motor for outdoor power equipment or a precision automotive part, they are engineered for a specific application. For example, Intel processors are designed for seamless integration into specific computer systems, ensuring optimal performance.

OEM software, like the Microsoft Windows pre-installed on new computers, is another example. It’s not a retail version but is licensed and optimized for the specific hardware it’s bundled with, providing full functionality without the retail packaging.

Customization capabilities set OEMs apart. Need a motor with specific torque characteristics for your outdoor equipment? An experienced original equipment manufacturer can modify their design to meet those exact requirements. This flexibility is invaluable for demanding applications in home improvement or automotive sectors.

Quality standards and durability are non-negotiable. OEM components undergo rigorous testing because a failure reflects on both the OEM and the final brand. This commitment to quality control ensures reliable end products.

Perfect compatibility is critical. OEM components are designed for flawless integration, ensuring seamless operation without performance compromises.

Warranty support from the OEM to the brand manufacturer creates a safety net, ensuring component issues are resolved professionally.

Real-World OEM Examples in Action

The automotive industry showcases OEM relationships at their finest. Your car is a collection of work from dozens of original equipment manufacturers. Companies like Bosch supply advanced fuel injection systems, while Brembo creates the high-performance stopping power found in sports cars from major manufacturers.

A great example is Hurst Performance. They started as an aftermarket gear shifter company, but their quality was so high that auto manufacturers began factory-installing their products. Hurst transformed into a respected OEM partner, proving how expertise can lift a brand.

A Detailed Look Back at Hurst

The technology sector operates on a massive network of OEM partnerships. Your laptop is a collection of OEM components—Intel processors, Microsoft software, and specialized memory modules, all designed to work together seamlessly.

Sporting goods also rely on OEMs. Specialized manufacturers like PS Stix produce high-quality wooden decks that are branded and sold by numerous skateboarding companies, allowing brands to focus on marketing and community building.

In home improvement and outdoor products, OEMs are the backbone of innovation. A specialized original equipment manufacturer can design a weather-resistant motor for outdoor lighting, while smart home devices rely on OEMs for sensors, microcontrollers, and communication modules.

Through our work connecting clients with manufacturing partners in Mexico, China, and Vietnam, we’ve seen how the right OEM relationships can transform a product concept into a market-leading reality.

OEM vs. The World: Key Manufacturing Models Compared

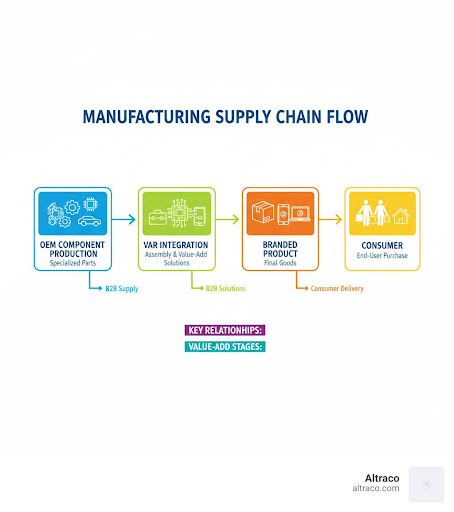

When navigating global manufacturing, understanding different business models is essential. While the original equipment manufacturer is key, they are part of a larger ecosystem including Value-Added Resellers, Original Design Manufacturers, and aftermarket suppliers. Each model serves a different purpose.

The choice between these relationships affects everything from production control and design ownership to final costs and speed to market. For companies with offshore manufacturing partners in countries like Mexico, China, and Vietnam, these distinctions are critical for managing complex supply chains.

Let’s break down these key relationships so you can make informed decisions about which partner best fits your needs.

OEM vs. Value-Added Reseller (VAR)

The partnership between an original equipment manufacturer and a Value-Added Reseller (VAR) is a highly effective division of labor. The OEM excels at manufacturing, while the VAR specializes in customization and customer solutions.

For example, a VAR might purchase high-quality industrial sensors from an OEM, then bundle them with specialized software and installation services to create a complete weather monitoring solution for agricultural clients. The VAR takes the OEM’s foundation and adds features to create a market-ready solution.

This relationship is common in technology and industrial applications. In the home improvement sector, VARs often take OEM-manufactured control systems and integrate them with custom interfaces and software integration to create smart home solutions. The OEM focuses on core manufacturing, while the VAR handles market-specific customer requirements.

The key difference lies in market reach. OEMs operate in the B2B space, while VARs often sell direct to consumer or to specific end-user markets, offering complete solutions rather than individual components.

Value-Added Resellers

OEM vs. Aftermarket Parts: A Quality and Cost Breakdown

For replacement parts, the choice between OEM and aftermarket is a classic quality-versus-cost decision. Understanding this is crucial for critical components in automotive, outdoor equipment, or home improvement applications.

Original equipment manufacturer parts are identical to the original components. They meet the same specifications, undergo the same quality control, and offer the same performance reliability. An OEM part guarantees a perfect fit and function.

Aftermarket parts come from third-party manufacturing companies and are designed to work similarly to OEM parts. Their appeal is a lower cost, sometimes 40-60% less than OEM alternatives. However, this savings often comes with trade-offs in quality variance and reliability concerns.

The challenge with aftermarket parts is inconsistency. While some rival OEM quality, others cut corners on materials or manufacturing. This quality variance is problematic for critical parts, where a lower-grade component can lead to premature failure, safety issues, or voided warranties.

Based on our experience, the performance implications of choosing aftermarket over OEM can be significant. While aftermarket parts offer short-term savings, the potential for increased downtime and reliability concerns often make OEM parts the better long-term investment for mission-critical components.

Aftermarket parts

OEM vs. Original Design Manufacturer (ODM)

The distinction between an original equipment manufacturer (OEM) and an Original Design Manufacturer (ODM) is a critical strategic decision. While both involve one company manufacturing for another, the key difference is design control and intellectual property (IP) ownership.

When you work with an OEM, you maintain complete control over your product’s design and specifications. You own the IP and have invested in R&D. The OEM is your manufacturing partner, building to your exact design. This approach offers product differentiation but requires significant upfront investment and a longer time-to-market.

An Original Design Manufacturer (ODM) operates on a white label or private label basis. ODMs design and engineer products that multiple companies can rebrand and sell. The ODM owns the design and IP, allowing clients to leverage their R&D investment for faster market entry and lower upfront costs.

For example, many similar-looking LED lighting fixtures sold under different brand names come from the same ODM. The ODM develops reliable designs that multiple brands can customize with their own packaging and branding.

The choice between OEM and ODM depends on your resources and goals. If you have unique product requirements and want complete control, an OEM partnership is best. If you need to enter a market quickly with proven technology, an ODM provides faster production and scalability with lower initial investment.

| Feature | Original Equipment Manufacturer (OEM) | Original Design Manufacturer (ODM) | Aftermarket |

|---|---|---|---|

| Design Input | Client provides full design and specifications | ODM designs, client rebrands/minor customizations | Independent manufacturer designs to match OEM specs |

| IP Ownership | Client typically owns the design/IP | ODM typically owns the design/IP | Independent manufacturer owns their design |

| R&D Investment | High for client | Low for client (leveraging ODM’s R&D) | Independent manufacturer’s R&D |

| Cost | Higher upfront (client R&D), lower per unit for bulk production | Lower upfront, potentially higher per unit for lower volumes | Varies, often lower than OEM, but quality can differ |

| Time-to-Market | Longer (requires client R&D and design phase) | Shorter (uses existing ODM designs) | Quick (parts are already designed and produced) |

| Branding | Client’s brand on final product, OEM name not usually visible | Client’s brand on final product, ODM name not usually visible | Independent brand, distinct from OEM |

| Typical Use Case | Custom, innovative products; strong brand identity; proprietary tech | Cost-effective, quick market entry; private label products | Replacement parts; cost-sensitive repairs/upgrades |

The Strategic Role of an OEM in the Global Supply Chain

Original equipment manufacturers are the unsung heroes of modern business, making entire industries possible. They allow companies to avoid building everything from scratch, a process that is neither practical nor cost-effective.

Working with an OEM transforms complex supply chains into streamlined operations. When companies partner with the right original equipment manufacturer, they can focus on their core competencies while leaving component production to the experts. This is about smart business strategy, not just saving money.

Supply chain efficiency improves dramatically with OEMs. Instead of managing dozens of manufacturing processes, companies can work with specialized partners. For our clients in the home improvement and automotive sectors, this means getting high-quality components faster and more reliably.

OEMs also drive innovation. They invest heavily in R&D within their specialties, pushing the boundaries of what’s possible. This continuous improvement benefits everyone, from the brand owner to the end consumer.

Quality control becomes more manageable with a specialized original equipment manufacturer. These companies build their reputations on consistency and reliability, which directly impacts brand reputation and customer satisfaction.

Perhaps most importantly, OEM partnerships provide risk reduction. Companies can rely on proven expertise instead of gambling on unfamiliar manufacturing processes. This is particularly valuable when navigating international manufacturing in countries like Mexico, China, and Vietnam.

How OEMs Drive Economies of Scale

Original equipment manufacturer partnerships create powerful economies of scale that transform manufacturing costs.

By producing for multiple clients, OEMs spread fixed costs over massive production volumes. This creates a cost reduction that a single company could not achieve alone. Production volume creates a cycle of efficiency: higher volumes justify better equipment, which drives costs down further. An OEM making automotive sensors might produce millions of units annually for multiple car manufacturers.

Specialization is key. When an original equipment manufacturer focuses exclusively on specific components, they become exceptionally good at making them. Their processes are refined and their quality control is sophisticated. This expertise translates into better products and lower costs.

Competitive pricing naturally follows from these efficiencies. OEMs can offer components at prices that would be impossible for individual companies to achieve in-house. This cost advantage is passed through the supply chain, ultimately benefiting consumers.

This model results in remarkable manufacturing efficiency. OEMs operate state-of-the-art facilities with optimized supply chains, streamlined workflows, and battle-tested quality systems.

economies of scale

The Business Case for OEM Partnerships

The decision to partner with an original equipment manufacturer is a turning point for growing companies, allowing them to be excellent at what matters most.

Focusing on core competencies is a practical benefit. Partnering with specialized OEMs allows our clients in industries like sporting goods to dedicate their energy to product design, brand building, and customer relationships, leading to better products and stronger market positions.

Access to expertise is immediate. Companies can tap into decades of specialized knowledge instead of spending years developing it in-house. For example, an outdoor products company can partner with an OEM that has already perfected weather-resistant coatings, saving significant time and money.

Reduced R&D costs are compelling. Working with an original equipment manufacturer that has already solved complex engineering challenges allows companies to allocate R&D budgets toward truly differentiating features.

Faster production and time-to-market can provide a crucial competitive edge. OEMs have established processes and trained workforces, enabling them to begin production much faster than a company setting up its own lines.

Scalability provides essential flexibility. OEMs can adjust production volumes based on demand, allowing businesses to scale up or down without massive capital investments. This is especially valuable for our clients in home improvement, where demand can be seasonal.

At Altraco, we’ve seen how the right OEM partnerships transform businesses. Our role is connecting companies with trusted manufacturing partners across Mexico, China, and Vietnam, ensuring they get quality components while navigating the complexities of international trade. Whether you’re developing automotive parts, outdoor equipment, or home improvement products, the right original equipment manufacturer partnership can accelerate your growth while improving your bottom line.

Frequently Asked Questions about Original Equipment Manufacturers

What does it mean when a product is OEM?

An “OEM” product or part is the genuine article, manufactured by an original equipment manufacturer for another company’s finished product. It is not a knockoff or substitute.

Contrary to a common misconception, “OEM” does not mean “fake” or “aftermarket.” OEM parts are the original components included in a new product. Every part in a new car, for example, is an OEM part made by a specialized manufacturer for that brand.

These aren’t copies or imitations. They’re authentic components produced by the specialized manufacturer and delivered to the brand that assembles and sells the final product. The original equipment manufacturer follows exact specifications and quality standards, ensuring each part fits perfectly and functions exactly as intended.

Is it worth paying more for OEM parts?

For critical components—like automotive brakes, engine parts, or motors in high-performance outdoor equipment—paying more for original equipment manufacturer parts is absolutely worth it.

Quality assurance is the biggest reason. OEM parts undergo rigorous testing and meet the exact specifications of your original product. They’re built to the same standards, guaranteeing a perfect fit and eliminating compatibility headaches.

Performance reliability is also crucial. OEM parts are designed to work seamlessly with every other component, maintaining the performance and efficiency your product was designed to deliver. Using OEM parts also helps maintain your warranty protection.

While OEM parts cost more upfront, they often deliver long-term value over short-term savings. Their superior durability means fewer repairs and a longer product lifespan, making the initial investment worthwhile.

That said, for non-critical or cosmetic components, a quality aftermarket option might make sense if you’ve verified its reliability. The key is to understand which parts are critical to safety and performance.

How does OEM software work?

Original equipment manufacturer software operates differently from retail software, mainly in its distribution and licensing.

Typically, OEM software comes pre-installed on hardware. The Windows OS on a new laptop is a common example, licensed in bulk by the computer manufacturer from Microsoft at a lower price than retail, but with certain restrictions.

Licensing agreements for OEM software are typically tied to specific devices. Unlike retail software that can be transferred between computers, an OEM license is usually married to the hardware it was first installed on. If that hardware fails, the license typically expires with it.

System-builder versions of OEM software are sold to those who build computers from components. These have similar licensing restrictions and are intended for installation on new systems.

The cost differences from retail versions are substantial due to bulk purchasing and licensing restrictions. Part of this savings is often passed on in the price of the new computer.

OEM software usually arrives without retail packaging or direct support from the software developer. Instead, the hardware manufacturer typically handles support.

This model allows software companies to achieve broad market penetration, manufacturers to offer ready-to-use systems, and consumers to get functional computers without installing software separately.

General Info on Microsoft OEM COA’s, CDs, Ect

Conclusion

We’ve explored manufacturing, from defining an original equipment manufacturer to comparing OEMs with Original Design Manufacturers (ODMs) and Value-Added Resellers (VARs). These partnerships form the backbone of products we use daily, from the brake systems in our cars to the motors in our power tools.

The key takeaway is that choosing the right partner—whether an OEM for custom parts, an ODM for quick market entry, or an aftermarket supplier—is critical. This decision impacts your R&D investment, time-to-market, brand reputation, and bottom line.

When you choose the right manufacturing partner, you’re not just buying components—you’re gaining access to decades of specialized expertise, proven quality systems, and the economies of scale that make competitive pricing possible. Whether you’re developing the next breakthrough in home improvement tools or launching an innovative line of outdoor gear, these relationships determine whether your vision becomes a market success.

At Altraco, we’ve spent over four decades helping companies—including Fortune 500s—steer exactly these decisions. We don’t just connect you with factories; we become your strategic partner in simplifying global supply chains. Our deep relationships with trusted manufacturers in Mexico, China, Vietnam, and beyond, combined with our tariff navigation expertise, mean you get the right manufacturing solution for your specific needs.

Whether you’re in home improvement, sporting goods, automotive parts, or outdoor products, we understand that every component matters. We’ve seen how the right OEM partnership can transform a good product idea into a market leader, and how the wrong choice can derail even the best-laid plans.

Ready to turn your manufacturing challenges into competitive advantages?

Explore our white label and contract manufacturing solutions.

Al is an entrepreneur, founder, and owner of multiple businesses, including Altraco, an outsourcing and contract manufacturing company. Working across multiple continents and trusted by Fortune 500 companies, Al finds innovative solutions to traditional supply chain challenges. He is a member of Vistage Worldwide.