Why Inventory Forecasting Services Matter for Global Manufacturing

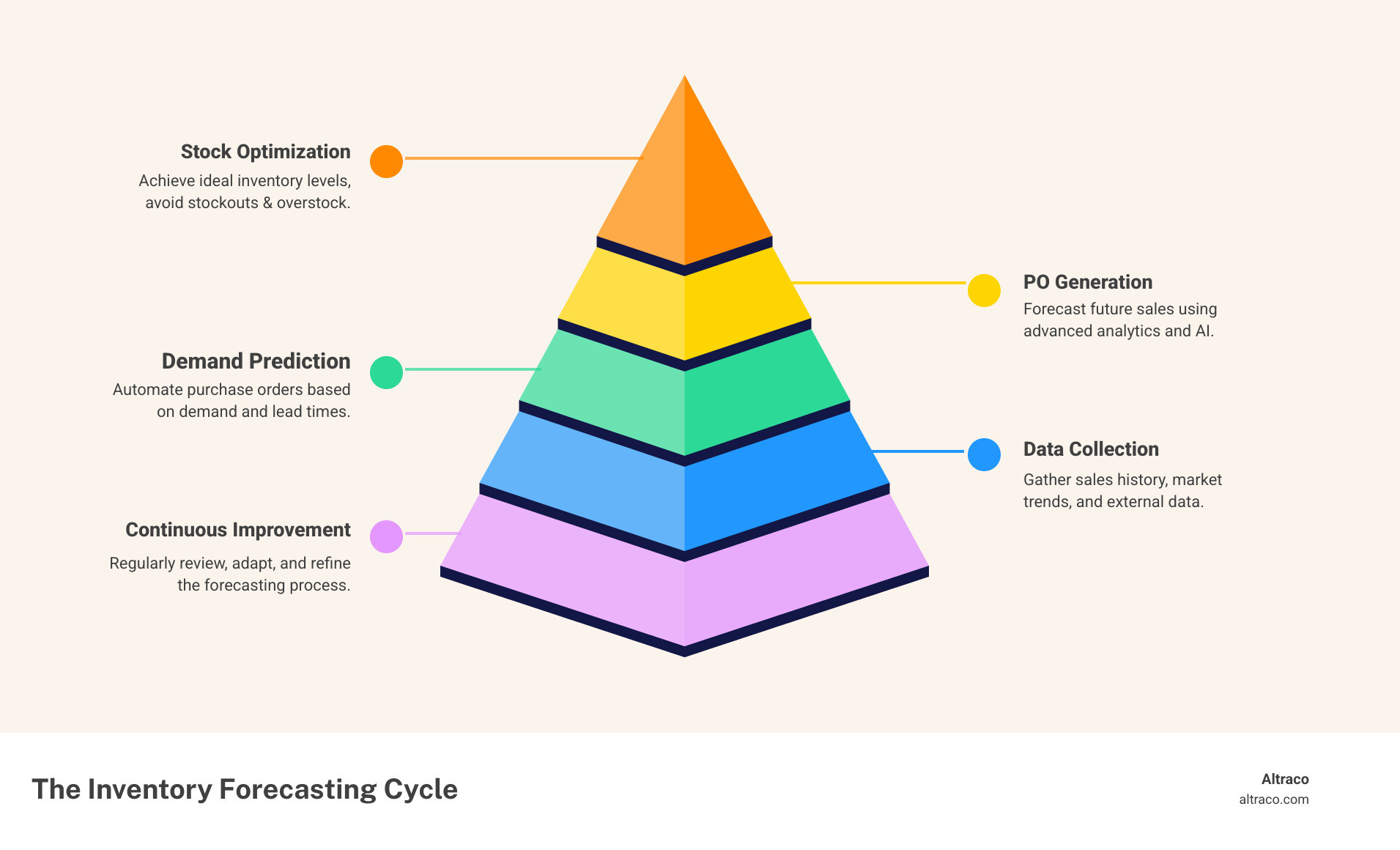

Inventory forecasting services help businesses predict future product demand using historical sales data, market trends, and advanced analytics to optimize stock levels, reduce costs, and prevent stockouts or overstock situations. These services typically include:

- Demand Prediction: Using statistical models (ARIMA) or AI-driven algorithms (LSTM) to forecast future sales

- Automated Purchase Orders: Generating PO recommendations based on supplier lead times and minimum order quantities

- Real-Time Analytics: Monitoring inventory levels, weeks on hand, and in-stock rates across multiple locations

- Integration Capabilities: Connecting with ERP systems, e-commerce platforms, and accounting software

- Cost Optimization: Reducing carrying costs, storage fees, and lost sales from stockouts

Running a business without inventory forecasting is like navigating a ship without a compass. You might end up with a mountain of products nobody wants, or worse, run out of hot-selling items when customers need them most. According to the research, smart inventory planning can save businesses up to 23 hours per week and significantly reduce human errors through automated, reliable planning.

The stakes are even higher for companies manufacturing overseas. When you’re sourcing home improvement products from Mexico, automotive parts from China, or sporting goods from Vietnam, getting inventory forecasting wrong doesn’t just mean lost sales—it means wasted shipping costs, tariff complications, and strained relationships with contract manufacturers. With recent tariff changes and supply chain disruptions, having accurate demand predictions has become essential for maintaining profitability.

This guide will walk you through everything you need to know about inventory forecasting services: the key features to look for, how different forecasting models work, implementation best practices, and how to overcome common challenges. Whether you’re managing a complex global supply chain or looking to optimize your current forecasting process, you’ll find actionable insights to make smarter, profit-driven decisions.

I’m Albert Brenner, and over 40 years of working with Fortune 500 companies on contract manufacturing, I’ve seen how inventory forecasting services can make or break a global supply chain—especially when navigating challenges like tariffs and multi-country sourcing. Through my experience at Altraco, I’ve helped businesses implement forecasting strategies that align production schedules in Mexico and Asia with real-world demand in the US market.

Why Your Business Needs Inventory Forecasting

In today’s global market, relying on guesswork for inventory management is a recipe for disaster. This is especially true for businesses dealing with international manufacturing, where lead times can be lengthy and supply chain disruptions are a constant threat. That’s why inventory forecasting services are not just a nice-to-have, but a critical tool for survival and growth. They help us optimize stock levels, reduce costs, improve customer satisfaction, and make truly data-driven decisions that impact our bottom line. For more insights on streamlining your operations, you can explore our expertise in Logistics Management Activities.

Optimize Stock Levels and Slash Costs

Imagine the perfect balance: enough product to meet every customer’s need, but not so much that it’s gathering dust in a warehouse. This equilibrium is precisely what effective inventory forecasting services aim to achieve. By accurately predicting demand, we can avoid the pitfalls of both overstocking and stockouts.

Overstocking, while seemingly safe, ties up valuable capital, incurs high carrying costs (storage, insurance, obsolescence), and can lead to markdowns that eat into profits. On the other hand, stockouts mean lost sales, disappointed customers, and potential damage to our brand reputation. Accurate demand forecasting minimizes these lost sales, further contributing to cost savings. Inventory forecasting software is a vital tool for businesses, offering significant cost reductions by helping us order only necessary inventory at the right time and minimizing carrying costs related to warehouse storage. This frees up cash flow that can be reinvested into growth. For our clients manufacturing automotive parts or outdoor products, these cost savings can be substantial, directly impacting their profitability.

Boost Customer Satisfaction and Loyalty

Happy customers are repeat customers. When a customer wants a product, they expect it to be available. Inventory forecasting services ensure that we consistently meet this expectation. By having the right products in stock at the right time, we prevent frustrating backorders and ensure a smooth purchasing experience.

Our research highlights that keeping customers happy is the name of the game in any business, and inventory forecasting is a key player. There are “no more empty shelves or disgruntled customers, just a well-stocked business ready to meet customer demand!” This consistent product availability builds trust and improves our brand’s reputation, fostering long-term customer loyalty. For home improvement goods or sporting goods, where seasonal demand can fluctuate wildly, ensuring availability is paramount to capturing market share and delighting our customers.

Make Smarter, Profit-Driven Decisions

Beyond just managing stock, inventory forecasting services empower us to make strategic, profit-driven decisions across our entire operation. The automation inherent in these services significantly reduces human error and frees up our teams from tedious manual tasks. Our research indicates that smart inventory planning can save businesses up to 23 hours per week, allowing employees to focus on more strategic initiatives.

With deep-dive insights and real-time reporting, we gain a clear understanding of market trends, sales patterns, and operational efficiency. This proactive approach allows us to fine-tune production schedules, optimize replenishment, and confidently allocate resources. As highlighted by Stackline, these insights can help us “know where to invest” and provide “a clear direction on how to maximize sales and profitability.” Their forecasting accuracy has “empowered us to make smarter decisions, optimize performance, and scale our business.” By changing supply chain visibility into actionable intelligence, we can ensure that every decision we make contributes directly to maximizing our profits. You can learn more about how to Transform supply chain visibility into profitability gains.

A Deep Dive into Inventory Forecasting Services

Modern inventory forecasting services are far more than just spreadsheets and educated guesses. They are sophisticated platforms designed to integrate seamlessly into our existing operations, providing data-driven insights, automating repetitive tasks, and delivering real-time visibility. This is crucial for managing diverse product lines, from home improvement supplies to automotive parts, especially when navigating complex global supply chains. Our Barcoding Inventory Management Software is an example of how integration can streamline operations.

Essential Features to Look For

When evaluating inventory forecasting services, certain features stand out as non-negotiable for achieving optimal results:

- Seamless Integrations (ERP, E-commerce, Accounting): The best forecasting software doesn’t operate in a silo. It integrates effortlessly with our existing Enterprise Resource Planning (ERP) systems, e-commerce platforms (like Shopify or Amazon Seller Central), and accounting software (like QuickBooks). This ensures that data flows smoothly and that our forecasts are always based on the most current sales, inventory, and order information. Without robust integrations, we’d be back to manual data entry and potential errors.

- Advanced Analytics and Data-Driven Forecasting: This is the core of any good service. Look for platforms that leverage sophisticated algorithms and predictive analytics to analyze historical sales data, identify trends, recognize seasonality, and even account for promotional lifts. The ability to incorporate multiple variables leads to more accurate demand predictions.

- Automated Purchase Order (PO) Generation: Once demand is forecast, the software should be able to automatically generate suggested purchase orders based on predefined parameters like lead times, minimum order quantities (MOQs), and service levels. This streamlines the purchasing process, reduces administrative burden, and ensures timely replenishment.

- Real-Time Dashboards and Reporting: We need immediate access to critical data. Real-time dashboards provide a bird’s-eye view of our inventory status, in-stock rates, projected weeks on hand, and potential stockouts or overages. Customizable reports allow us to drill down into specific product lines, vendors, or locations, facilitating quick decision-making.

- Customization Options: Every business is unique. The software should allow us to define a wide range of forecasting and reordering parameters at the company, vendor, and even item levels. This flexibility ensures that the forecasts align with our specific business goals and supply chain realities, such as varying lead times for products sourced from China versus Mexico.

- Multi-Location Support: For businesses operating across multiple warehouses, retail stores, or even different fulfillment centers (like Amazon FBA), the software must be able to manage and optimize inventory across all locations, providing a centralized, up-to-date view.

Understanding Forecasting Models: Statistical vs. AI

The accuracy of inventory forecasting services hinges on the models they employ. Broadly, these fall into two categories: traditional statistical models and advanced AI/Machine Learning (ML) models. Understanding the differences helps us choose the right tool for our specific needs.

Statistical Models (e.g., ARIMA):

ARIMA (AutoRegressive Integrated Moving Average) is a classic statistical model that has been a workhorse in time series forecasting for decades. It’s best suited for short-term, linear time series forecasting when historical data follows a clear, predictable pattern. ARIMA models identify patterns like trends and seasonality in data.

- Pros: Relatively simple to understand and implement, computationally less intensive, and can provide quick, reliable forecasts for stable demand. Our research notes that ARIMA is best for quick and reliable forecasts if inventory demand follows predictable, linear trends.

- Cons: Requires data stationarity (meaning the statistical properties of the series do not change over time), and manual parameter tuning can be complex. ARIMA struggles with high volatility, irregular trends, and incorporating multiple external influencing factors. It’s less accurate with complex, non-linear patterns.

AI and Machine Learning Models (e.g., LSTM):

LSTM (Long Short-Term Memory) is a type of recurrent neural network, a deep learning model particularly adept at processing and predicting sequences, making it highly effective for time series data. LSTM excels at capturing complex, non-linear patterns in large datasets.

- Pros: Highly accurate for long-term forecasting, can handle volatile and irregular trends better than statistical models, and can incorporate a multitude of influencing factors (e.g., promotions, weather, economic indicators). It excels at capturing complex, non-linear patterns.

- Cons: Requires significantly larger datasets for training, is computationally intensive, and can be more complex to interpret and implement.

Many modern inventory forecasting services integrate AI-driven models like LSTM while often allowing statistical approaches like ARIMA for comparison or for specific product segments with stable demand. The choice between them often depends on the complexity and volume of our data, the desired forecast horizon, and the volatility of our product demand. For home improvement products with stable demand, ARIMA might suffice, but for rapidly changing outdoor product trends, LSTM’s power is invaluable.

Here’s a quick comparison:

| Feature | ARIMA (Statistical) | LSTM (AI/Deep Learning) |

|---|---|---|

| Best For | Stable, linear data; Short-term forecasts | Complex, volatile data; Long-term forecasts |

| Pros | Simple, fast; Less data required; Interpretable | High accuracy; Captures non-linear trends; Handles volatility |

| Cons | Less accurate with volatility; Requires data stationarity; Manual tuning | Requires large datasets; Computationally complex; Less interpretable |

How to Successfully Implement and Manage Forecasting Software

Adopting new inventory forecasting services is a strategic undertaking that requires careful planning and execution. It’s not just about installing software; it’s about integrating a new way of thinking and operating into our business. The goal is to ensure a smooth transition, maximize the benefits, and overcome any problems along the way.

A Practical Guide to Implementing Inventory Forecasting Services

Successful implementation of inventory forecasting services hinges on a few critical steps:

- Data Preparation: This is arguably the most crucial step. Our forecasts are only as good as the data we feed them. We must ensure our historical sales data is clean, accurate, and complete. This involves identifying and correcting inconsistencies, removing outliers (like one-off bulk sales that skew averages), and consolidating data from various sources (e.g., e-commerce platforms, ERP systems). For businesses manufacturing home improvement goods or sporting goods, this might mean reconciling sales data from different retail channels and direct-to-consumer sales.

- Employee Training Programs: Even the most advanced software is useless if our team doesn’t know how to use it effectively. We need to invest in comprehensive training programs that equip employees with the necessary knowledge and skills. This includes understanding the software’s features, interpreting forecasts, generating reports, and making data-driven decisions. Fostering a data-driven culture means empowering our team to trust and leverage the insights provided by the forecasting tool.

- Integration with Existing Systems: As mentioned earlier, seamless integration is key. We need to ensure the forecasting software connects smoothly with our existing ERP, CRM, and accounting systems. This automates data flow, reduces manual effort, and ensures consistency across all our operational tools.

- Continuous Improvement: Implementation isn’t a one-and-done event. We need to continuously review and update our inventory forecasting processes. This involves regularly evaluating forecast accuracy, fine-tuning model parameters, and adapting to changing market conditions or business strategies. This iterative approach ensures that our forecasting remains relevant and effective over time.

For companies engaged in global manufacturing, understanding these steps is even more critical. Our expertise in Why International Sourcing Services Are Critical For Modern Manufacturing can guide you through the complexities of data integration across international operations.

Overcoming Common Adoption Challenges

While the benefits of inventory forecasting services are clear, implementing them isn’t always a walk in the park. Businesses might face several challenges, but with a proactive approach, these can be effectively overcome.

- Dealing with Poor Data Quality: This is a recurring theme. Inaccurate or incomplete historical data can lead to skewed forecasts and undermine trust in the system.

- Solution: Invest time upfront in data cleansing and validation. Establish clear data entry protocols and leverage integrations to minimize manual errors. Consider a phased approach, starting with products that have cleaner data.

- Managing Demand Volatility: Some products, like seasonal outdoor equipment or trending automotive accessories, experience highly volatile demand, making accurate forecasting difficult.

- Solution: Use AI-driven models (like LSTM) that are better equipped to handle non-linear patterns and external factors. Incorporate market intelligence, promotional plans, and even social media trends into the forecasting process. Regularly review and adjust forecasts based on real-time sales data.

- Choosing the Right Solution: The market is flooded with various inventory forecasting services. Selecting one that fits our specific business size, budget, industry, and complexity can be daunting.

- Solution: Clearly define our needs and priorities. Conduct thorough research, request demos, and read reviews. Consider scalability, integration capabilities, and the level of support offered. Focus on solutions that cater to our specific manufacturing needs, whether it’s for home improvement or sporting goods.

- Securing Budget and Buy-in: Implementing new software often requires significant investment in terms of both money and resources. Gaining internal support from all stakeholders, from finance to operations, is crucial.

- Solution: Clearly articulate the ROI by highlighting potential cost savings, increased efficiency, and improved customer satisfaction. Present case studies and pilot programs to demonstrate tangible benefits. Emphasize how improved forecasting strengthens the entire supply chain, a key concern for global sourcing.

By anticipating these challenges and having strategies in place to address them, we can ensure a smoother adoption process and open up the full potential of our inventory forecasting services. For broader strategies on managing your global supply chain, check out Unlocking Global Sourcing Strategies For Manufacturing Success.

Frequently Asked Questions

When delving into inventory forecasting services, many questions arise. Let’s tackle some of the most common ones to provide clarity.

How does forecasting software handle new products with no sales history?

This is a classic chicken-and-egg problem: how do you forecast demand for something that has no past sales? Fortunately, inventory forecasting services have clever ways to address this.

Typically, they use a method called “forecasting by proxy” or “like-item forecasting.” This involves:

- Using data from similar products: If we’re launching a new outdoor product, we can use the sales history of a similar existing product in our catalog as a proxy. The software can then apply adjustments based on anticipated market reception, pricing, or marketing efforts.

- Market trend analysis: For entirely novel products, the software can analyze broader market trends, industry growth rates, and competitor performance to generate an initial forecast.

- Open-to-Buy (OTB) planning: Some advanced systems offer “Open-to-Buy” planning specifically for new SKUs. This allows us to set sales targets or cover forecasted sales for new products and then work backward to determine the necessary inventory levels.

- Manipulating historical data: As our research notes, some tools allow users to “easily copy and manipulate historical data from a similar existing product to generate a forecast for a new product introduction.” This provides a starting point that can be refined as actual sales data begins to accumulate.

This approach allows us to make informed initial purchasing decisions, even without a direct sales history, minimizing risk for new home improvement or automotive parts.

What is the difference between inventory forecasting and demand planning?

While often used interchangeably, inventory forecasting and demand planning are distinct but closely related concepts within supply chain management. Think of them as two sides of the same coin:

- Inventory Forecasting: This is the act of predicting future sales or demand for a specific product over a specific period. It’s a quantitative process that uses historical data, statistical models, or AI algorithms to generate a numerical prediction. It answers the question, “How much will we sell?”

- Demand Planning: This is a broader, more strategic process that takes the inventory forecast as its input and then develops a plan to meet that predicted demand. It involves coordinating across various departments (sales, marketing, operations, finance, purchasing) to decide on production schedules, inventory levels, promotional activities, and procurement strategies. It answers the question, “How will we meet the predicted sales?”

Inventory forecasting is a critical component of demand planning. The forecast provides the “what,” and demand planning determines the “how.” Our Global Production Strategy relies heavily on accurate forecasting feeding into comprehensive demand planning.

What are the benefits of AI in inventory forecasting services?

The integration of Artificial Intelligence (AI) and Machine Learning (ML) has revolutionized inventory forecasting services, offering significant advantages over traditional methods.

- Handles Complexity and Volatility: AI models, particularly deep learning networks like LSTM, excel at recognizing complex, non-linear patterns in data that statistical models might miss. This is invaluable for products with erratic demand, such as certain sporting goods or outdoor products affected by weather or trends.

- Incorporates More Variables: AI can process and integrate a vast array of external factors that influence demand, including seasonality, promotional activities, economic indicators, competitor actions, and even evolving consumer behavior. This leads to a more holistic and accurate prediction. Our research highlights that AI-powered predictions can help us stay ahead of shifting demand and protect profitability by incorporating these dynamic variables.

- Higher Accuracy for Long-Term Forecasts: While statistical models are often good for short-term, stable predictions, AI tends to perform better for long-term forecasts, especially when dealing with volatile environments.

- Continuous Learning: Many AI systems are designed to continuously learn and adapt as new data becomes available. This means their forecasts can improve over time without constant manual recalibration.

- Automation and Efficiency: AI can automate much of the forecasting process, from data ingestion to model selection and prediction generation, significantly reducing the manual effort and time required.

AI-driven inventory forecasting services lead to more precise predictions, enabling us to optimize stock levels more effectively, reduce costs, and avoid both stockouts and overstock. This makes supply and demand planning smarter with AI, as emphasized by Supply and demand planning made smarter with AI.

Conclusion: Building a Resilient and Profitable Supply Chain

As we’ve explored, inventory forecasting services are indispensable tools for any business aiming to thrive in today’s dynamic market. They are the compass guiding us through the complexities of supply and demand, ensuring we avoid the treacherous waters of overstocking and stockouts. From optimizing stock levels and slashing costs to boosting customer satisfaction and enabling smarter, profit-driven decisions, the benefits are clear and far-reaching. By leveraging advanced analytics, whether through traditional statistical models or cutting-edge AI, we gain unprecedented visibility and control over our inventory.

For businesses manufacturing products like home improvement goods, automotive parts, or sporting goods, accurate forecasting is crucial for managing complex global supply chains. The intricacies of sourcing from countries like Mexico, China, or Vietnam, coupled with the ever-present challenge of tariffs (like those recently deliberated by the United States Supreme Court regarding tariffs), make precise inventory planning non-negotiable.

At Altraco, we understand these challenges intimately. As a trusted offshore contract and private label manufacturing partner, we simplify global supply chains for our clients. We leverage decades of experience, trusted factory relationships, and tariff navigation expertise to deliver quality, on-time products with significant cost savings. Our role is to ensure that your optimized inventory plans are supported by reliable production and delivery, no matter where in the world your products are made. By partnering with us, you can implement robust supply chain strategies, from sourcing in Mexico or Vietnam to managing tariffs, ensuring your inventory forecasting services translate into tangible success.

Embracing sophisticated inventory forecasting services is not just about keeping pace; it’s about gaining a strategic advantage. It’s about building a resilient, agile, and ultimately more profitable supply chain that can adapt to any market condition.

Are you ready to transform your inventory management and open up new levels of efficiency and profitability? Optimize your supply chain with our Integrated Supply Chain Services.

Al is an entrepreneur, founder, and owner of multiple businesses, including Altraco, an outsourcing and contract manufacturing company. Working across multiple continents and trusted by Fortune 500 companies, Al finds innovative solutions to traditional supply chain challenges. He is a member of Vistage Worldwide.