Finding the right manufacturing partner can make or break your product launch and long-term business success. The partner you choose will directly impact your costs, quality, and ability to scale, ultimately affecting your market competitiveness.

Quick Answer: What is a Manufacturing Partner?

- Definition: A business that transforms raw materials into finished products for your company.

- Types: Direct manufacturers, contract manufacturers, trading companies, and sourcing agents.

- Key Benefits: Cost reduction, quality control, scalability, and access to specialized expertise.

- Primary Considerations: Quality standards, production capacity, cost structure, and communication.

For large enterprises, a poor choice can lead to quality issues, delivery delays, and significant financial losses. Conversely, the right partner becomes a strategic asset that drives growth.

The manufacturing landscape has evolved, with companies increasingly leveraging global capabilities in countries like Mexico, China, and Vietnam. This shift offers substantial cost savings—often 40-70% lower than domestic options—but introduces complexities in quality control and supply chain management.

“You’ve created a prototype, collected feedback, raised funding, and now you’re ready to bring your product to market. The next step: finding the right factory to make your dream a reality,” as one industry expert puts it. This decision requires careful evaluation of production capabilities, quality systems, and partnership potential.

As Albert Brenner, co-owner of a contract manufacturing company with over 40 years of experience, I’ve helped Fortune 500 companies find the right manufacturing partner for home improvement, sporting goods, automotive, and outdoor products. My experience shows that companies who invest time in proper partner selection consistently outperform those who rush the process.

Understanding Your Options: Manufacturing Partner Types and Sourcing Locations

Choosing your manufacturing partner shapes everything from production costs to delivery timelines. This is especially crucial for complex products like automotive components or precision outdoor gear.

The manufacturing world offers several types of partners, and understanding them helps you find the perfect match for your business goals.

Types of Manufacturing Partners

- Direct Factories: You work directly with the facility making your product. This often yields the best unit costs but requires you to manage everything from quality control to logistics. It’s best for those with experience and large order volumes.

- Contract Manufacturers: They handle the entire production process based on your specifications. This is often the sweet spot for companies making home improvement tools, sporting goods, or automotive parts. You control the design while they handle production complexities. At Altraco, we specialize in this contract manufacturing approach, simplifying the process for our clients.

- Trading Companies and Sourcing Agents: These intermediaries connect you with factories. They add a markup but can be valuable for smaller businesses or those new to international manufacturing, often handling smaller quantities with more flexibility.

- Wholesalers and Distributors: They buy pre-made products in bulk to resell. They are generally not a fit for custom manufacturing projects.

| Feature | Domestic Manufacturing | Overseas Manufacturing |

|---|---|---|

| Cost | Higher labor and operating costs | Lower labor and operating costs, but potential hidden fees |

| Lead Time | Shorter, easier to manage | Longer, subject to shipping delays |

| Quality Control | Easier oversight, often higher standards | Requires robust QC systems, can be challenging |

| Communication | Simpler, fewer language/time zone barriers | Potential for language barriers, time zone differences |

| Volume | Often better for smaller runs, but can scale | Ideal for higher-volume orders, lower unit costs |

Domestic manufacturing offers proximity, simpler communication, and shorter lead times. However, higher labor costs can make products less price-competitive.

Overseas manufacturing in countries offering the cheapest overseas manufacturing costs can reduce production expenses by 40-70%, a major advantage for high-volume goods. The key is finding partners who bridge the gap between cost savings and quality control.

At Altraco, we’ve spent decades building trusted relationships with factories in strategic locations like Mexico, Vietnam, and China. We make overseas manufacturing feel as comfortable as working with a domestic partner by handling international trade complexities, navigating tariff structures, and ensuring quality standards. Based in California, we offer the cost advantages of global manufacturing with the reliability and communication of a domestic partner.

The Search: How to Find and Vet Your Ideal Manufacturing Partner

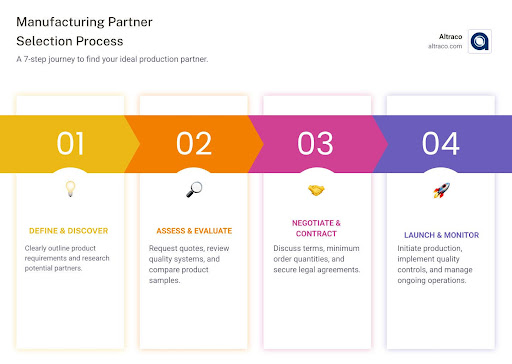

Once you’ve decided on the type of manufacturing partner and location, the detective work begins. This stage requires thorough research and due diligence to find a partner that can deliver on their promises.

Effective Methods for Finding Potential Partners

Use multiple search methods to cast a wide net, especially for specialized products like home improvement tools or automotive parts.

- Online Manufacturing Directories: Platforms like ThomasNet (U.S.), Maker’s Row (smaller U.S. businesses), MFG (global), and Kompass (international) are excellent starting points. For overseas options, Alibaba is dominant; look for suppliers with “Gold,” “Verified,” and “Trade Assurance” status. AliExpress, Indiamart, and Sourcify are other valuable resources.

- Industry Referrals: Your network can provide insights no directory can match. Ask fellow business owners, mentors, and industry contacts for their experiences.

- Trade Shows: These events allow for face-to-face interaction, letting you see product samples and gauge professionalism firsthand.

- Google Searches: Use advanced search terms like “wholesale,” “supplier,” or “distributor” along with your product category and filter by region to uncover hidden gems.

- NAICS Codes: The North American Industry Classification System helps you systematically search professional directories for specific types of factories in the U.S. and Canada.

Instead of starting from scratch, you can leverage Altraco’s global sourcing expertise. We have a pre-vetted network of trusted partners specializing in home improvement, sporting goods, automotive, and outdoor products in Mexico, China, and Vietnam.

Vetting Your Shortlist: Essential Questions to Ask

Once you have a shortlist, it’s time to vet them carefully.

- Minimum Order Quantity (MOQ): Understand their volume requirements. MOQs vary dramatically based on product complexity and manufacturing processes.

- Pricing: Get detailed breakdowns for production and samples. Understand how unit costs change with volume.

- Turnaround Time: Ask about both sample development and full production lead times, factoring in shipping for overseas partners.

- Payment Terms: Most factories expect a 30-50% upfront deposit. Be wary of partners demanding 100% upfront.

- Capabilities: Confirm they have the right expertise and equipment for your product category (e.g., injection molding for automotive parts, weatherproof material experience for outdoor gear).

- Quality & References: Ask about their Quality Management System (QMS) and request client references. A reputable factory will gladly provide them.

For comprehensive support through this vetting process, explore our contract manufacturing services. We handle these evaluations daily.

Communicating Your Vision: Designs and Requirements

Clear communication is essential to avoid costly mistakes. Provide detailed documentation to leave nothing to interpretation.

- Technical Specifications: Create detailed written specs covering every dimension, material, finish, and performance standard.

- Computer-Aided Design (CAD) Files: Use standard formats like STEP or IGES to provide precise, measurable instructions.

- Tech Packs: For products like outdoor gear, these comprehensive documents should include all design details, materials, measurements, and assembly instructions.

- Bill of Materials (BOM): List every component and raw material to ensure accurate quotes and production planning.

- Prototypes: A physical sample can help manufacturers reverse-engineer specifications and identify potential production challenges.

If you need help creating professional design files, freelance platforms like Fiverr and Upwork are great resources. Clear communication is the foundation of a successful partnership.

The Cornerstone of Success: Quality, Compliance, and Cost

Three factors will make or break your product’s success: manufacturing quality, regulatory compliance, and a clear understanding of your true costs. These are critical for products like automotive parts that demand flawless performance or outdoor gear that must withstand harsh conditions.

Why Your Partner’s Quality Management System (QMS) Matters

A QMS is a formal system that documents how a company manages quality from start to finish. It’s the backbone of your manufacturer’s operations and ensures:

- Predictable Quality: Every product meets your exact specifications, which is non-negotiable for safety-critical automotive parts or high-performance sporting goods.

- Reliability: You know what to expect from each order, allowing you to make promises to your customers with confidence and protect your brand reputation.

- Efficiency: Fewer defects and less rework lead to faster turnaround times and lower costs.

- Problem-Solving: A documented system provides a framework for quickly identifying and fixing issues when they arise.

We’ve seen how a strong quality system transforms a manufacturing relationship. For more details, you can learn about our quality control processes and find comprehensive information on quality systems.

Evaluating a Potential Manufacturing Partner on Compliance

Your manufacturing partner must meet strict regulatory and ethical standards to protect your business from legal and reputational damage.

- Certifications: Look for relevant standards from the International Organization for Standardization (ISO), such as ISO 9001 for quality management.

- Regulatory Adherence: Ensure your partner understands and complies with the specific safety and material requirements for your product in all target markets.

- Ethical Practices: Verify safe working conditions, fair wages, and environmental responsibility. We actively monitor compliance with laws like the Uyghur Forced Labor Prevention Act (UFLPA) to prevent forced labor in supply chains.

- Factory Audits: Independent audits provide an objective assessment of a partner’s quality systems, working conditions, and ethical standards. We conduct thorough audits to ensure we only work with reputable manufacturers.

Balancing Cost vs. Quality: Calculating Your Margins

The cheapest quote is rarely the best option. To understand your profitability, you must calculate your gross margin and account for all costs.

Gross Margin = (Revenue – Cost of Goods Sold) / Revenue

When manufacturing overseas, be aware of hidden costs that can erode your savings. These include:

- Shipping, customs, and tariffs.

- Currency exchange rate fluctuations.

- Third-party quality control inspections.

- Tooling expenses for custom molds or dies.

- Rework and defect costs.

A slightly higher unit price from a manufacturer with excellent quality control often costs less in the long run. At Altraco, we help clients steer tariffs, understand true costs, and find the sweet spot between competitive pricing and uncompromising quality.

Sealing the Deal: From Samples to Production

You’ve researched, vetted, and crunched the numbers. Now it’s time to turn your vision into a physical product. This stage involves careful sample evaluation and smart negotiation to solidify your partnership.

The Critical Role of Product Samples

Product samples are your final dress rehearsal. This step is crucial for developing precision automotive parts or rugged outdoor gear and can save you from costly surprises.

- Request and Test: Order samples from your top 2-3 manufacturers based on your detailed specifications. When they arrive, test them rigorously for functionality and durability. Put them through their paces.

- Establish a “Golden Sample”: Once you approve a sample, it becomes your “Golden Sample”—the physical benchmark for quality. Using control samples for accountability is essential for maintaining consistency. Ensure both you and your manufacturer keep a dated and signed copy.

- Accept Iteration: The first sample is rarely perfect. The back-and-forth revision process is where you refine your product to meet your exact vision and market demands.

Negotiation Strategies for a Win-Win Partnership

Good negotiation creates a partnership that benefits both parties, setting the stage for a successful long-term relationship.

- Negotiating MOQs: Minimum Order Quantities aren’t always set in stone. If a manufacturer’s MOQ is too high, propose a smaller initial order with a commitment to larger quantities later. Many factories are flexible if they see long-term potential.

- Payment Terms: The standard 30-50% upfront deposit is common, but as trust builds, you may be able to negotiate more favorable terms to help manage your cash flow.

- Building Relationships: Building Strong Supplier Relationships based on regular communication and mutual respect is key. A strong relationship means your partner will be more willing to help when unexpected issues arise.

- Contract Essentials: Your agreement must clearly outline specifications, quality standards, payment terms, lead times, and intellectual property (IP) protection. For overseas manufacturing, ensure your IP is protected through non-disclosure agreements and by registering patents and trademarks in the manufacturing country. We help clients ensure their IP remains secure through stringent contracts and vetted factory relationships.

Frequently Asked Questions about Finding a Manufacturing Partner

When searching for the right manufacturing partner, a few questions always come up. With decades of experience in overseas manufacturing for home improvement, sporting goods, and automotive parts, we have the answers.

How do I protect my intellectual property when manufacturing overseas?

Protecting your IP requires a multi-layered approach. Your U.S. patent or a standard NDA may not be enforceable in another country.

- Use Enforceable Agreements: Work with legal counsel to draft Non-Disclosure Agreements (NDAs) and Non-Compete Agreements that are valid in both your country and the manufacturer’s.

- Register Your IP Locally: Register your patents and trademarks in the country of manufacture. This is a critical step that is often overlooked.

- Work with a Trusted Partner: The best defense is working with a partner who vets factories for their integrity. At Altraco, our partners sign comprehensive confidentiality agreements before seeing your designs. We act as your “boots on the ground” to ensure your innovations stay protected.

What is the difference between a manufacturer and a supplier?

Though often used interchangeably, these terms have distinct meanings.

- A manufacturer is the company that physically makes your product from raw materials. Working directly with them gives you more control over quality and cost.

- A supplier is a broader term that can include manufacturers, but also wholesalers, distributors, or sourcing agents who may not produce the goods themselves.

When we talk about finding a manufacturing partner, we focus on building a direct relationship with the entity that will produce your product.

What is a typical Minimum Order Quantity (MOQ)?

MOQs vary widely based on the product, materials, and production process. A simple item might have an MOQ of 500-1,000 units, while a complex automotive component requiring custom tooling could require 5,000 or more.

Product complexity and material costs are major drivers of MOQs, as factories need to cover their setup and tooling expenses.

The good news is that MOQs are often negotiable. We help clients negotiate lower initial MOQs by leveraging our long-term factory relationships and demonstrating a clear path to future growth. Being transparent about your situation can open the door to finding a flexible solution.

Conclusion

Finding the right manufacturing partner is a critical journey that requires research and careful consideration, but the rewards are immense. A great partner is more than a vendor—they are an extension of your team.

You’ve learned how to identify partner types, weigh the benefits of overseas manufacturing, and vet candidates for quality and compliance. The keys to a successful relationship are clear communication, robust quality systems, and fair negotiation.

The complexities of global manufacturing—time zones, logistics, and tariffs—can feel overwhelming. However, these challenges shouldn’t deter you from the competitive advantages of a strategic partnership.

This is where Altraco’s experience makes a difference. For decades, we’ve helped businesses steer these complexities with confidence. We have built trusted relationships with factories in Mexico, China, and Vietnam that specialize in home improvement, sporting goods, automotive, and outdoor products.

We act as your outsourced manufacturing team, handling everything from factory selection to final quality control. We steer tariffs, manage logistics, and ensure your intellectual property is protected. The Fortune 500 companies we serve trust us to deliver quality products on time and with significant cost savings.

Ready to turn your product idea into a reality?

Explore our comprehensive manufacturing services to see how we can support your needs. For more expert guidance on global manufacturing, visit our Insights page.

Let’s make your next great product happen together.

Al is an entrepreneur, founder, and owner of multiple businesses, including Altraco, an outsourcing and contract manufacturing company. Working across multiple continents and trusted by Fortune 500 companies, Al finds innovative solutions to traditional supply chain challenges. He is a member of Vistage Worldwide.