Private label vendors are manufacturers that produce goods for other companies to sell under their own brand. This model offers significant advantages over traditional reselling.

Top Private Label Vendor Categories:

- Contract Manufacturers – Custom production to your specifications.

- Dropshipping Suppliers – Handle inventory and fulfillment.

- B2B Marketplaces – Connect with global manufacturers.

- Specialized Producers – Focus on specific product niches.

Key Benefits:

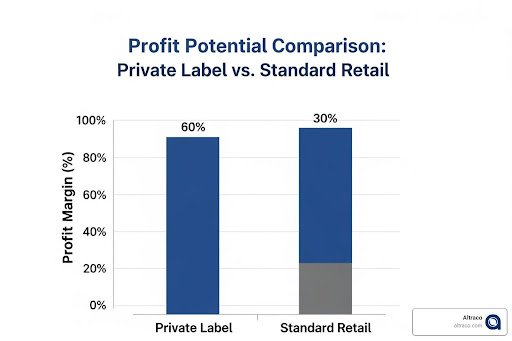

- Higher profit margins (often 20-40% better).

- Complete brand control and product exclusivity.

- Faster market entry without building factories.

- Lower initial investment.

The global private label market is projected to grow from $746.1 billion in 2022 to $2,049.7 billion by 2032, reflecting a major shift in how businesses compete. Unlike wholesale, private labeling lets you create custom products, controlling everything from materials and specifications to packaging and pricing.

The challenge isn’t just finding vendors, but finding the right ones who can ensure quality, steer international regulations, and maintain a reliable supply chain.

As co-owner of Altraco, a contract manufacturing firm with 40 years of experience, I’ve helped businesses partner with private label vendors in Mexico, China, and Vietnam. We specialize in steering through tariff changes, supply chain disruptions, and quality control to deliver reliable offshore manufacturing solutions.

Understanding the Private Label Model: Benefits, Risks, and Key Differences

The private label vendors market is a massive global industry, with store brands making up 17% of the U.S. retail market and over 30% in parts of Europe. This growth is driven by consumers who recognize that private label products offer name-brand quality without the high price tag. For businesses, this creates huge opportunities for profitability and brand building.

Partnering with the right private label vendors gives you complete control over your product’s journey. We’ve spent decades building relationships with trusted manufacturers in Mexico, China, and Vietnam to help companies develop innovative home improvement tools, sporting goods, automotive parts, and outdoor equipment without the headaches of in-house production. You can learn more about our contract manufacturing services.

Private Labeling vs. White Labeling: What’s the Difference?

Many businesses confuse private labeling and white labeling, but they are distinct strategies.

- Private Labeling is like commissioning a custom-made product. A manufacturer creates an item exclusively for your company, sold only under your brand. You control the design, materials, and specifications, resulting in a unique brand asset with high control and custom specifications. For example, launching a line of automotive parts with unique engineering is private labeling.

- White Labeling is like buying an off-the-rack product and adding your logo. A manufacturer produces a generic item for multiple retailers to rebrand. It’s faster to market but offers lower customization and no exclusivity.

While white labeling offers speed, private labeling provides the brand control and exclusivity needed to build a lasting business.

The Strategic Advantages of a Private Label Approach

Businesses from startups to Fortune 500 giants accept private labeling for its compelling financial and strategic advantages.

- Higher profit margins: By working directly with private label vendors, you cut out middlemen, reducing costs and increasing profits.

- Complete brand control: You dictate every aspect of the product, from its core function to its aesthetic, weaving your brand identity into every detail.

- Product exclusivity: You own the designs and formulations, preventing competitors from selling the same item.

- Stronger customer loyalty: A unique, high-quality product builds trust and turns one-time buyers into brand advocates.

- Market adaptability: You can develop or modify products much faster than if you relied on third-party brands, allowing you to adapt to market trends in real-time.

Navigating the Risks and Legal Considerations

While beneficial, private labeling has risks that require careful management.

- Product liability: When you put your name on a product, you are responsible for its safety. A defect could lead to legal action, making quality assurance critical. We implement Proven Tips to Improve Quality in Overseas Manufacturing for all clients.

- Manufacturer reliability: A vendor that fails to deliver on time or produces substandard goods can damage your brand. Our rigorous vetting process focuses on building long-term relationships with trusted factories.

- Intellectual property protection: You must ensure your designs don’t infringe on existing patents or trademarks while also protecting your own IP from being copied.

- Supplier agreements: Comprehensive, legally binding contracts are essential. They should clearly outline product specifications, quality standards, delivery schedules, and IP ownership to protect your interests.

How to Find and Select the Right Private Label Vendors

Finding the right manufacturing partner is crucial for success. The best private label vendors act as true partners, sharing your commitment to quality and growing with your business. This process requires diligence, whether you’re launching home improvement tools, sporting goods, automotive parts, or outdoor equipment.

Key Factors for Choosing a Manufacturer

When evaluating potential private label vendors, we assess their ability to be a strategic partner, not just a supplier.

- Product specialization: A manufacturer specializing in your category offers invaluable expertise and can help you avoid costly mistakes.

- Quality certifications: Certifications like ISO indicate a commitment to consistency and quality. Our quality control process ensures these standards are met.

- Production capacity: The vendor must be able to scale production as your business grows to avoid becoming a bottleneck.

- Customization capabilities: A true private label partner can accommodate unique designs and material requirements, helping your product stand out.

- Transparent pricing: Look for detailed cost breakdowns covering tooling, materials, and labor. Hidden fees can destroy profit margins.

- Communication skills: Prompt, clear communication is essential to avoid expensive misunderstandings, especially across time zones.

- Ethical standards: We work only with factories that follow fair labor practices and environmental regulations to protect your brand’s reputation.

- Geographic location: Location impacts shipping costs, tariffs, and lead times. Our network spans Mexico, Vietnam, China, and other key hubs.

Where to Find Reliable Private Label Vendors

Finding reliable private label vendors requires a multi-channel approach that combines digital research with relationship building.

- Online B2B marketplaces: Platforms like Alibaba offer vast options but require careful filtering to identify capable manufacturers for your product category.

- Supplier directories: Curated resources like Thomasnet (for domestic partners) provide more detailed and verified company information.

- Industry trade shows: These events are invaluable for meeting manufacturers face-to-face, examining samples, and discussing capabilities.

- Professional networks and referrals: Working with an experienced partner like Altraco provides immediate access to our pre-vetted network of trusted factories in Mexico, China, and Vietnam.

The Vetting Process: From First Contact to Final Agreement

This stage transforms a list of potential vendors into a trusted partner. Rushing this process often leads to problems.

- Initial outreach: Present your project professionally with clear specifications. The response reveals much about their communication and interest.

- Request for quotation (RFQ): Submit detailed requirements to compare pricing and how well each vendor understands your project.

- Sample evaluation: The physical product is the ultimate test. Insist on samples to verify quality and capabilities before making a commitment.

- Factory audits: On-site visits are essential for assessing production facilities, quality control systems, and ethical standards.

- Negotiating MOQs: Most factories have minimum order quantities, but these are often negotiable for partners with long-term growth potential.

- Finalizing contracts: A comprehensive agreement protects both parties by detailing specifications, quality standards, IP rights, payment terms, and delivery schedules. This builds a foundation of trust, as we explore in our article about the value of buyer-supplier relationships.

Building and Launching Your Private Label Brand

Once you’ve selected a vendor, the focus shifts to product development, branding, and preparing for a successful market launch. This is where your vision becomes a reality.

Elements of a Successful Private Label Business Model

A thriving private label business requires a solid foundation built on several key components.

- Niche selection: Instead of competing in a broad market, focus on a specific segment. For example, target “ultra-lightweight camping equipment” rather than just “outdoor gear.”

- Strong brand identity: Your brand is more than a logo; it’s the story, values, and visual appeal that create an emotional connection with customers.

- Superior product quality: Your reputation depends on product performance. Quality drives trust, positive reviews, and word-of-mouth marketing.

- Effective marketing strategy: A comprehensive plan spanning digital channels, content, and targeted campaigns is needed to connect with your ideal customers.

- Robust supply chain management: An efficient supply chain prevents delays and keeps your business running smoothly. We use tools like Supplier Scorecards to monitor vendor performance and ensure operational stability.

Examples of Successful Private Labeling in Action

Private labeling is a powerful strategy for businesses of all sizes.

- Home Improvement: Retailer-branded power tools that are engineered to specific performance standards can rival established names while offering better value.

- Outdoor Products: A specialty retailer can launch a unique line of custom-designed camping equipment, such as tents engineered for specific weather conditions.

- Sporting Goods: Fitness studios or retailers can create branded equipment, like the custom yoga mats from Pravacana Mats, that meet specific functional or aesthetic needs.

- Automotive Parts: Companies can develop branded performance accessories, like custom exhaust systems or suspension components, by partnering with experienced private label vendors to control engineering and design.

Marketing Your New Brand and Avoiding Common Pitfalls

A successful launch requires smart marketing and awareness of potential pitfalls.

Your packaging design is your silent salesperson, attracting customers and communicating your brand’s value. For digital marketing, use SEO to appear in search results and social media campaigns to build a community.

Avoid these common pitfalls:

- Poor quality control: Inconsistent quality will quickly destroy customer trust and your brand’s reputation.

- Underestimating costs: Budget for the total landed cost, including manufacturing, shipping, customs, and marketing—not just the per-unit price.

- Weak branding: A generic brand will get lost. Invest in professional branding that communicates your unique value.

- Ignoring legal compliance: Cutting corners on product safety standards or IP laws can lead to lawsuits and recalls.

- Failing to build strong supplier relationships: Treat your private label vendors as partners. Nurturing these relationships is key to long-term success.

Frequently Asked Questions about Private Label Vendors

Here are answers to some of the most common questions we receive about private labeling.

How much does it cost to start a private label business?

While a simple project could start for around $1,000, a serious venture in home improvement, sporting goods, or automotive parts typically requires a larger investment. Key initial costs include:

- Sample costs: $50 to $500 per sample, depending on complexity. This is a crucial step that should not be skipped.

- Minimum Order Quantity (MOQ) costs: This is often the largest upfront expense, potentially ranging from $5,000 to $20,000+ for an initial production run.

- Branding expenses: Budget $500 to $5,000+ for logo design, packaging, and potential tooling for custom molds.

Remember to also budget for shipping, customs, and marketing. The global private label market is projected to reach USD 2,049.7 billion by 2032, indicating a massive opportunity for those willing to invest.

What are typical Minimum Order Quantities (MOQs)?

MOQs vary significantly by product and manufacturer. Simpler items may have MOQs in the hundreds, while complex products requiring custom tooling can require thousands of units.

However, negotiation is key. Many private label vendors are flexible on initial MOQs if they see potential for a long-term partnership. We often negotiate lower initial quantities for our clients by demonstrating a clear growth plan. That higher volume usually means a lower per-unit cost.

Is private labeling profitable?

Yes, private labeling can be highly profitable when executed correctly. The primary reasons are:

- Higher profit margins: By working directly with manufacturers, you cut out middlemen, often resulting in 30-50% better margins than traditional retail.

- Complete control over pricing: You set the retail price based on your costs and brand value, not in reaction to competitors selling identical items.

- Reduces direct competition: Since you are the only source for your product, you compete on brand and quality, not just price.

Profitability ultimately depends on combining a great product with effective branding and marketing. The most successful businesses focus on building a brand, which commands premium prices and customer loyalty.

Conclusion

The world of private label vendors offers a direct path to higher profit margins, complete brand control, and the product exclusivity needed to build a loyal customer base. It is your pathway to market leadership.

However, the journey from concept to a successful product requires a partner who understands global supply chains, quality assurance, and international regulations. This is especially true when developing home improvement tools, sporting goods, automotive parts, or outdoor equipment.

At Altraco, we simplify offshore manufacturing. Based in Thousand Oaks, California, we leverage decades of experience and on-the-ground teams in Mexico, China, and Vietnam to manage your supply chain. We handle tariff changes, ensure quality standards, and manage logistics to deliver your product on time and on budget.

We are committed to making your vision a reality with the reliability and cost savings that have made us a trusted partner for businesses worldwide, including Fortune 500 companies.

Ready to transform your product ideas into market-leading brands? Explore our private label manufacturing services in California and let’s simplify your supply chain journey together.

Al is an entrepreneur, founder, and owner of multiple businesses, including Altraco, an outsourcing and contract manufacturing company. Working across multiple continents and trusted by Fortune 500 companies, Al finds innovative solutions to traditional supply chain challenges. He is a member of Vistage Worldwide.