Why Chinese Manufacturing Partnership Matters for Global Supply Chains

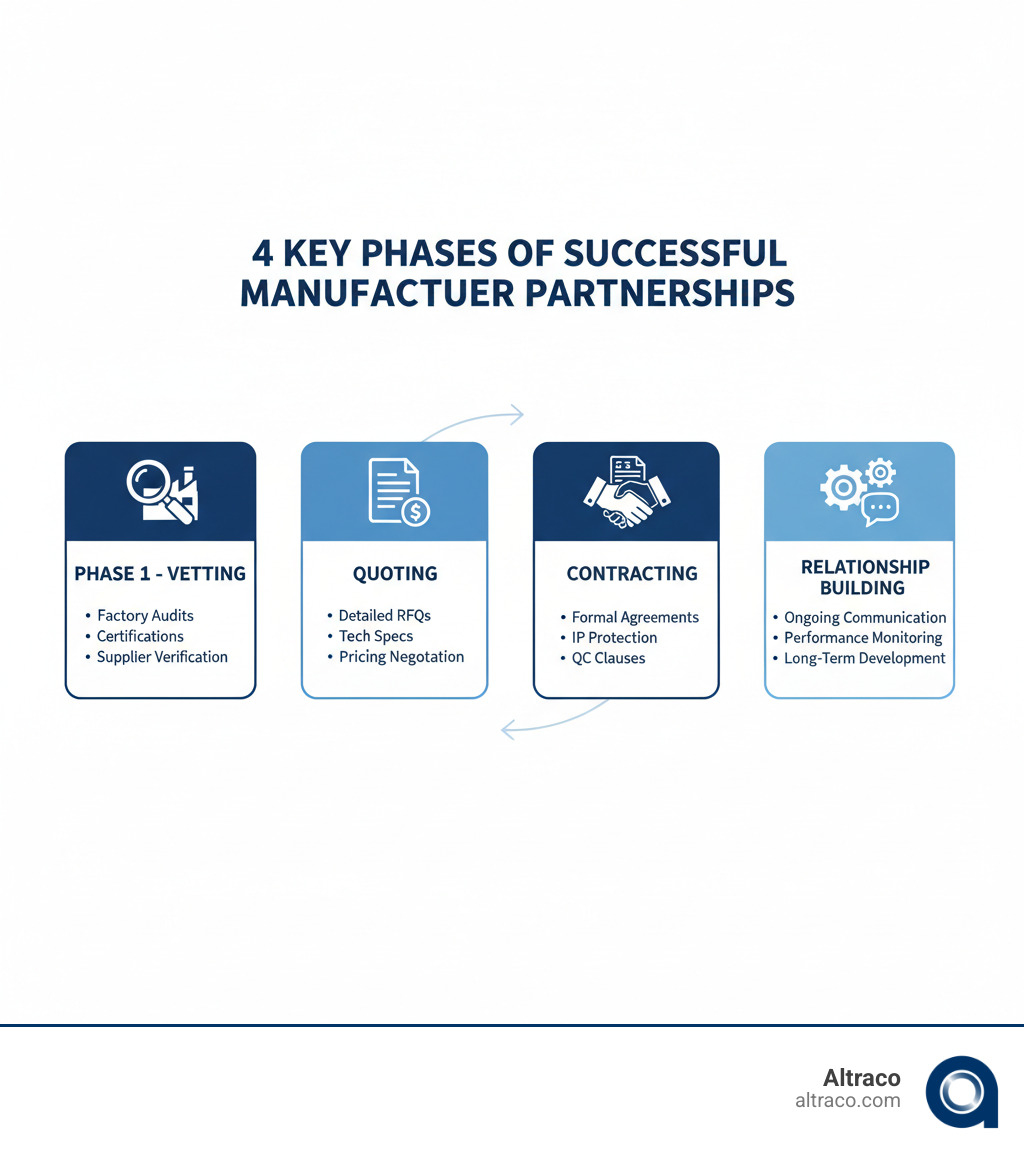

How to partner with Chinese manufacturers successfully requires a strategic approach across four key phases:

- Vetting – Verify supplier legitimacy through factory audits and certifications

- Quoting – Submit detailed RFQs with technical specifications and quality requirements

- Contracting – Establish formal agreements with IP protection and quality control clauses

- Relationship Building – Foster long-term partnerships through consistent communication and mutual respect

China remains the world’s manufacturing powerhouse, accounting for 28.7% of global manufacturing output. This dominance presents both opportunities and challenges.

The benefits are clear: cost-effectiveness, scalability, and advanced infrastructure. China’s manufacturing ecosystem offers high efficiency for home improvement, sporting goods, automotive parts, and outdoor products.

However, success isn’t guaranteed. IP risks, quality control issues, and communication barriers can derail partnerships. Thriving companies use a systematic approach to supplier selection, negotiation, and relationship management.

As Albert Brenner, co-owner of Altraco with over 40 years of manufacturing experience, I’ve helped Fortune 500 companies steer how to partner with Chinese manufacturers across multiple industries. Through proven factory relationships and expertise in managing tariff complexities, we’ve simplified global manufacturing for brands seeking reliable, cost-efficient production solutions.

A Step-by-Step Guide on How to Partner with Chinese Manufacturers

Starting a manufacturing partnership in China requires a clear plan. With the right approach, how to partner with Chinese manufacturers becomes much more straightforward.

The first step is finding potential partners, but many companies stumble by casting too wide a net or relying on flashy online profiles. The real work is proper vetting—separating genuine manufacturers from trading companies and verifying their capabilities.

Anyone can claim to manufacture automotive parts or sporting goods, but proof is essential. We’ve seen partnerships fail when a supposed ‘manufacturer’ is just a middleman.

Factory audits are crucial. A legitimate manufacturer welcomes questions about production capacity, quality certifications, and facility tours. Trading companies often deflect or give vague answers about their ‘partner factories.’

The smart approach involves diversifying your supply chain from the start. Don’t put all your eggs in one basket, especially with complex products like home improvement tools or outdoor equipment. Having multiple qualified partners gives you flexibility and reduces risk.

Effective Online Platforms and Vetting Techniques

B2B marketplaces are a starting point, but their supplier verification badges can be unreliable. What actually matters are business licenses, ISO 9001 certification, and recent test reports. A real manufacturer will provide these without hesitation.

Spotting trading companies masquerading as manufacturers is tricky. As one frustrated buyer asked on Quora: “How do I find the actual manufacturer of products in China? I find a product I like, but then I keep running into trading companies.” The answer is to ask specific questions about machinery, production capacity, and factory addresses—then verify those details.

Reading reviews carefully reveals patterns. While one negative review may be a fluke, multiple complaints about quality or communication are a red flag.

Onsite checks remain the gold standard. If you can’t visit personally, partner with someone who can. Remote audits only tell part of the story; you need boots on the ground to verify capabilities, especially for complex products like automotive parts.

| Method | Cost | Time | Reliability |

|---|---|---|---|

| B2B Platforms | Low (initial) | Moderate | Variable |

| Trade Shows | Moderate (travel) | Moderate | High (face-to-face) |

| Sourcing Agents | Moderate (fee) | Low | High (verified network) |

The Role of Sourcing Agents and Trade Shows

Sourcing agents act as your guide in unfamiliar territory. A good agent brings established networks, negotiation power, and on-the-ground support that can save you time and money. Experienced agents can reduce sourcing costs by 10-20% through their networks and market knowledge.

Crucially, they serve as a cultural and linguistic bridge, helping build relationships and prevent misunderstandings that cause delays.

Trade shows offer genuine human connection. Major events in China create opportunities for face-to-face meetings and immediate product inspection. At a trade show, you can instantly gauge a manufacturer’s professionalism, inspect samples, and discuss technical requirements—insights impossible to get from email alone.

At Altraco, we’ve built our reputation on these proven relationships and decades of manufacturing experience. Our approach combines the efficiency of established networks with the personal touch of direct factory relationships. Whether you’re sourcing home improvement products or outdoor equipment, we help Fortune 500 companies and growing businesses alike steer the complexities of global manufacturing.

For companies considering their options, our insights on Supply Chain Globalization: Is It Worth the Risk? and Choosing a Contract Manufacturer: Pro Tips provide additional guidance.

Crafting the Perfect Request for Quote (RFQ) and Initial Communication

Once you’ve shortlisted potential manufacturers, the next step is issuing a Request for Quote (RFQ). A well-crafted RFQ is more than a price inquiry; it’s your first formal communication, demonstrating professionalism and setting the stage for a productive partnership. The more precise your instructions, the better the result.

Key Elements of a Winning RFQ

A comprehensive RFQ leaves no room for ambiguity. When we help clients prepare RFQs for home improvement, sporting goods, automotive parts, or outdoor products, we ensure they include:

- Detailed Product Specifications: This is paramount. Specify the exact material type (e.g., PP, PVC, PET), grade, color (Pantone or RAL codes), and relevant certifications. For a metal part, specify the alloy, finish, and hardness. Include detailed dimensions, tolerances, and critical features. Failing to have detailed, prototype-tested, manufacture-ready engineer’s drawings is a common mistake.

- Technical Drawings (CAD): Provide professional CAD drawings or 3D models. These are universally understood and eliminate language barriers.

- Material Requirements: Clearly outline all materials, including any specific brands or origins if crucial.

- Target Price: Providing a realistic target price can help manufacturers propose solutions within your budget.

- Payment Terms: Suggest your preferred payment schedule (e.g., 30% upfront, 70% upon completion). Be wary of requests for 100% upfront.

- Shipping Details: Specify your desired Incoterms (e.g., FOB, EXW, CIF, DDP), which define responsibility for shipping costs and duties.

- Packaging Requirements: Detail inner and outer packaging, labeling, and any specific protection needed.

- Minimum Order Quantity (MOQ) and Annual Volume Estimates: Be truthful about your estimated order sizes.

- “Golden Sample” Request: Ask for a pre-production sample to serve as the quality benchmark for mass production.

A detailed RFQ prevents future problems by ensuring accurate quotes and mutual understanding from the start.

Navigating Cultural Differences in Early Communication

Understanding cultural nuances is a strategic part of partnering with Chinese manufacturers, as Western business practices can be misinterpreted.

- Guanxi (Relationships): This concept of mutual trust and obligation is paramount. Invest time in building rapport beyond simple transactions.

- Building Rapport: A brief, friendly opening shows genuine interest in a long-term relationship.

- Using Titles Respectfully: Respect for hierarchy is key. Use titles and surnames (e.g., “Manager Li”).

- Professionalism: Maintain a professional demeanor with prompt responses and clear communication.

- Avoiding Email-Only Contact: Use video calls for important discussions to avoid misunderstandings and build rapport. As one Amazon seller noted, “I think that being patient, taking the time to understand their business culture, and befriending my suppliers has made my life as an Amazon seller that much more enjoyable.”

- Understanding “Yes” Doesn’t Always Mean Yes: A direct “no” is often avoided to save face. A “yes” may mean “I understand,” not “I agree.” Listen for hesitation and rephrase questions to clarify commitment.

- Face-Saving Culture: “Face” (dignity, reputation) is vital. Avoid public criticism; address issues privately and constructively to preserve the relationship.

By embracing these cultural considerations, you lay the groundwork for a more effective partnership, which is key to how to partner with Chinese manufacturers successfully.

Securing the Deal: Contracts, IP Protection, and Quality Control

After finding manufacturers and exchanging RFQs, the next step is securing the deal properly. This phase creates a foundation that protects your interests and ensures you receive what you ordered.

Just as a house needs a solid foundation, your partnership needs strong legal frameworks, IP protections, and quality controls. These elements determine whether your partnership thrives or fails when learning how to partner with Chinese manufacturers.

Companies that rush this stage often face quality issues and IP theft. Those who invest in a solid legal and quality framework build lasting, successful partnerships for products like home improvement goods, sporting goods, automotive parts, or outdoor gear.

How to Partner with Chinese Manufacturers While Protecting Your IP

IP concerns are real when manufacturing in China, but they are manageable. China uses a “first-to-file” IP system, meaning the first to register a trademark or patent owns it in China, regardless of who used it first elsewhere.

NNN (Non-disclosure, Non-use, Non-circumvention) agreements are your first line of defense. They are specifically crafted for the Chinese legal system. Before sharing sensitive designs, get a robust NNN agreement signed. Crucially, the NNN must be written in Chinese and be enforceable under Chinese law to be effective.

Registering your trademarks and patents in China is essential. Your brand name, logo, and unique product designs need to be registered with Chinese authorities to give you legal standing.

Your contract must include clear IP ownership clauses stating you own all IP related to your product, including any modifications made during manufacturing. Having a solid contract greatly reduces infringement risks.

For sensitive components, consider sourcing parts from different manufacturers to prevent any single factory from replicating your entire product.

The Importance of a Formal Contract and Rigorous Quality Control

A formal contract is your roadmap to success. For contract enforceability in China, the agreement must be in Chinese, comply with Chinese law, and use correct legal names for all parties. Errors can render it unenforceable.

Arbitration clauses are often best for dispute resolution, as arbitration is typically faster and more cost-effective than Chinese courts. Specify the arbitration body and location in your contract.

The contract must define quality standards explicitly, referencing your technical drawings and the approved “golden sample.” Our guide on Quality Control can help establish these standards.

Define sample approval processes clearly: who has final approval, what happens if samples fail, and how many revision rounds are included.

Use third-party inspection services for independent verification. Pre-production inspections check raw materials, during-production inspections catch issues early, and final random inspections check finished goods before shipment.

This multi-stage approach is part of our Proven Tips to Improve Quality in Overseas Manufacturing and helps you Maintain Quality Control Program.

Proper quality control is smart business. Good manufacturers appreciate partners who are serious about quality, as it shows a commitment to mutual success.

Nurturing a Strong, Long-Term Partnership

After the first successful order, the work of shifting from customer to true partner begins. Like any relationship, it takes time and effort to build something valuable for both sides.

Many businesses mistakenly treat their Chinese manufacturers as mere vendors. Thriving companies, including many Fortune 500s we work with, understand that building trust and fostering mutual benefit creates a competitive advantage beyond cost savings.

Investing in the relationship yields significant benefits: your manufacturer will be more willing to accommodate rush orders, suggest improvements, prioritize your quality, and alert you to supply chain disruptions. This is the power of how to partner with Chinese manufacturers for the long haul.

Our approach at Altraco centers on this philosophy. With decades of experience managing manufacturing relationships across China, Vietnam, and Mexico, we know the strongest partnerships are built on mutual respect. For deeper insights, explore our thoughts on The Value of Buyer-Supplier Relationships and Strong Supplier Relationships.

Beyond the First Order: How to Partner with Chinese Manufacturers for Long-Term Success

The journey to a trusted partnership requires intentional effort. Regular communication forms the foundation—not just when problems arise, but during quiet times too.

Factory visits, whether in-person or virtual, show you’re invested in their operations and help you find opportunities for improvement together.

Clear, constructive feedback accelerates quality and strengthens the relationship. When issues arise, focus on solutions rather than blame, remembering the cultural importance of “face.”

Supplier scorecards provide an objective framework for these conversations. Tracking metrics like quality, on-time delivery, and communication creates a data-driven foundation for improvement. Our guide on Supplier Scorecards explains how to implement these systems.

Collaborative problem-solving is a rewarding aspect of long-term partnerships. Invite your manufacturer to contribute ideas on materials, processes, or design. This transforms them from a service provider into an innovation partner.

Showing appreciation for exceptional performance strengthens these bonds. A simple acknowledgment of their efforts creates goodwill that pays dividends.

As trust grows, you’ll be in a stronger position to negotiate better terms. More importantly, you’ll have a reliable partner who understands your business intimately.

One experienced seller captured this perfectly: “I think that being patient, taking the time to understand their business culture, and befriending my suppliers has made my life as an Amazon seller that much more enjoyable.” This human element is often the key to a thriving partnership.

At Altraco, we nurture these enduring relationships. Whether you’re manufacturing home improvement products, sporting goods, automotive parts, or outdoor equipment, we help you create partnerships that deliver consistent quality, innovation, and cost advantages.

Frequently Asked Questions about Partnering with Chinese Manufacturers

We’ve guided countless businesses through their manufacturing journeys in China, and certain questions come up repeatedly. Here are some practical insights based on our decades of experience helping clients exploring how to partner with Chinese manufacturers.

What are the biggest risks and how can I mitigate them?

Manufacturing overseas has manageable risks. Once you know what to watch for, you can steer them safely.

IP theft is a major concern but is largely preventable. Use robust NNN agreements, register your trademarks and patents in China (a first-to-file system), and include clear IP ownership clauses in your contracts.

Quality fade (a gradual decline in standards) can sneak up on you. Combat this with a multi-stage inspection process: pre-production, in-production, and final inspections. Set clear quality benchmarks in your contract and consider surprise inspections.

Communication barriers can cause significant headaches. We solve this with bilingual contracts, trusted translators, and visual communication like drawings and photos.

Scams exist, but thorough vetting, never paying 100% upfront, and working with experienced partners are the best protection.

How do I handle tariffs when importing from China?

Understanding tariffs is essential, as they can make or break your profit margins. The landscape, including Section 301 tariffs, shifts frequently.

Understanding tariff codes is your first step. Each product is classified under a specific Harmonized System (HS) code; getting this wrong can be costly.

Calculating your true landed cost means factoring in everything: tariffs, shipping, insurance, and import fees, not just the factory price.

Tariff engineering, which can involve minor design or material modifications, can sometimes change a product’s classification and significantly reduce tariff exposure.

Our expertise in navigating the Complexities of Tariffs is invaluable. We monitor regulatory changes and help you Steer Section 301 Tariffs, so you don’t have to.

Should I manufacture in China, Vietnam, or Mexico?

This common question has no single answer; it depends on your product, market, and supply chain goals. Here’s a breakdown based on our experience managing manufacturing in these regions.

China excels with its advanced infrastructure, vast supplier networks, and scalability. It’s often best for complex home improvement products, sophisticated automotive parts, or technical outdoor gear.

Vietnam offers compelling advantages for cost diversification and risk management, with lower labor costs and different trade relationships.

Mexico delivers significant nearshoring benefits for North American businesses, including shorter lead times and reduced shipping costs, making it ideal when speed-to-market is critical.

At Altraco, we specialize in managing manufacturing partnerships across China, Vietnam, Mexico, and other countries. We analyze your specific needs—for a precision automotive component or a durable sporting goods product—and help you select the optimal location. Our global expertise in home improvement, sporting goods, automotive parts, and outdoor products means we can guide you to the right manufacturing solution, wherever it may be.

Conclusion

Successfully navigating how to partner with Chinese manufacturers is a journey that requires careful planning, relationship building, and a commitment to excellence. Every step matters, from initial vetting and detailed RFQs to establishing rock-solid contracts and nurturing long-term partnerships.

Thriving companies know a manufacturing partner is an extension of your team, committed to delivering quality home improvement products, automotive parts, sporting goods, and outdoor equipment.

At Altraco, we’ve walked this journey with countless businesses. With decades of hands-on experience and factory relationships spanning China, Vietnam, and Mexico, we know success is about finding the right partner who shares your vision for quality and reliability.

The complexities—tariffs, cultural nuances, quality control, IP protection—can feel overwhelming. With the right guidance and proven systems, these challenges become competitive advantages. Our clients, including Fortune 500 companies, consistently achieve significant cost savings while maintaining high quality standards.

Don’t let the intricacies of international manufacturing keep you on the sidelines. Whether you’re developing a new product or optimizing your supply chain, the opportunities are there.

Ready to explore what’s possible? Dive deeper into our manufacturing insights on our Blog, or Let Altraco’s experts simplify your global manufacturing journey. We’re here in Thousand Oaks, serving clients worldwide, and we’d love to help you forge the strong partnerships that drive manufacturing excellence.