Why Electronics Contract Manufacturing Services Matter for Global Production

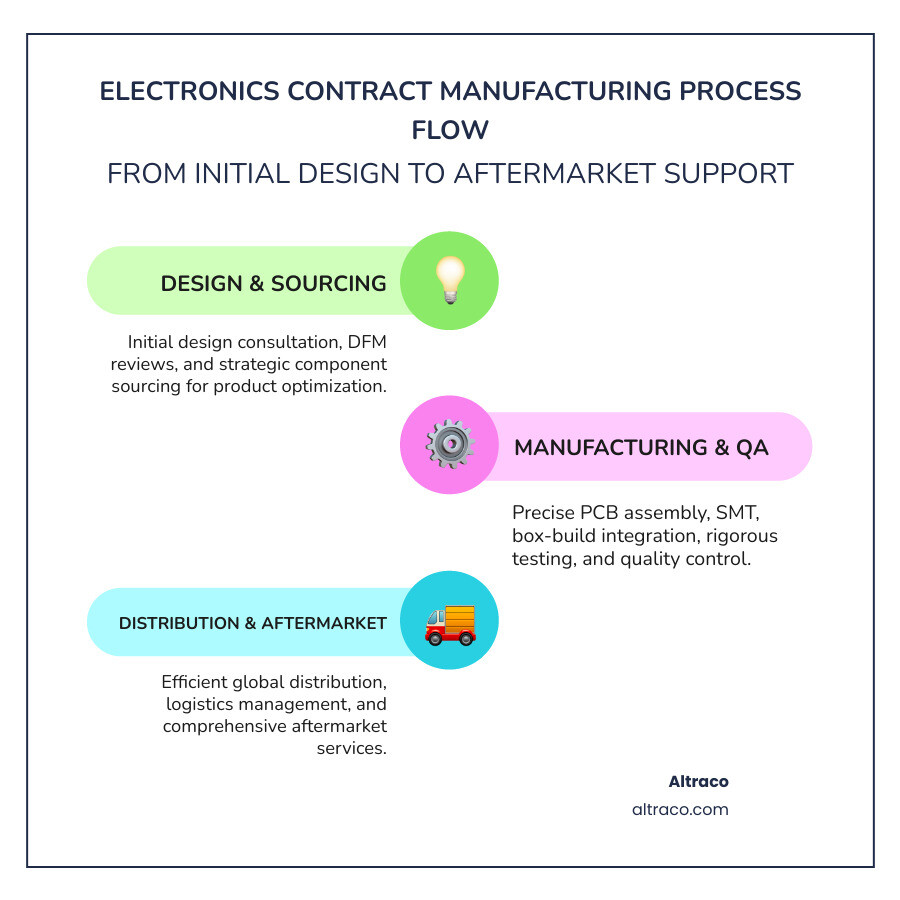

Electronics contract manufacturing services are specialized solutions where companies outsource the design, manufacturing, testing, and distribution of electronic components to an expert partner. This allows original equipment manufacturers (OEMs) to offload complex production to firms with advanced facilities and skilled teams.

Key services include:

- Design and engineering support

- PCB assembly and system integration

- Quality assurance and testing

- Global supply chain management

- Aftermarket support and repair

The global Electronics Manufacturing Services (EMS) market was valued at $504.2 billion in 2023 and is projected to hit $707.5 billion by 2030, growing at a CAGR of 4.94%. This growth is driven by rising demand for consumer and automotive electronics and the need for specialized manufacturing skills.

For large enterprises, partnering with an electronics contract manufacturer is a strategic move to manage complexity. As products in sectors like sporting goods, automotive, and home improvement become more advanced, in-house manufacturing becomes prohibitively expensive. The real challenge lies in navigating global supply chains, managing component lifecycles, and mitigating risks like tariffs and trade disruptions.

Recent shifts in international trade policy have made strategic manufacturing partnerships more critical than ever. Companies need partners who can source production across regions like Mexico, China, and Vietnam to optimize costs and ensure reliability.

I’m Albert Brenner, co-owner of a contract manufacturer. For 40 years, I’ve helped Fortune 500 companies steer offshore electronics contract manufacturing services for home improvement, sporting goods, and automotive products. My firm leverages factory relationships across multiple countries to deliver quality, on-time, and cost-effective solutions, even amid tariff and supply chain challenges.

What is Electronics Contract Manufacturing (ECM)? A Deep Dive

At its core, electronics contract manufacturing services (ECM) involve a specialized third-party provider taking responsibility for producing electronic products for an Original Equipment Manufacturer (OEM). Think of us as the expert builders behind the scenes, allowing you to focus on innovation and market strategy.

This comprehensive partnership extends far beyond simple assembly. We offer a full suite of capabilities, becoming an extension of your team to bring your electronic products to life. When you need a reliable partner, explore our Contract Manufacturing Services.

Defining the Acronyms: ECM, EMS, and CEM

The industry uses several acronyms interchangeably:

- ECM (Electronics Contract Manufacturing): The overall term for outsourcing electronics production.

- EMS (Electronics Manufacturing Services): The collective name for the services provided (e.g., assembly, testing).

- CEM (Contract Electronics Manufacturer): The company that provides the services.

In short, an OEM partners with a CEM (like us) to receive EMS as part of an ECM arrangement.

OEM vs. EMS Provider: Understanding the Key Differences

The relationship between an Original Equipment Manufacturer (OEM) and an Electronics Manufacturing Services (EMS) provider is symbiotic. An OEM designs a product and owns the intellectual property (IP), focusing on R&D, branding, and sales. An EMS provider, or CEM, specializes in the manufacturing process, leveraging economies of scale in production and procurement. By partnering with an EMS provider, OEMs avoid the massive capital expenditure and operational complexity of running their own factories.

Here’s a quick breakdown:

| Feature | Original Equipment Manufacturer (OEM) | Electronics Manufacturing Services (EMS) Provider |

|---|---|---|

| Core Function | Product design, R&D, branding, sales | Manufacturing, assembly, testing, supply chain |

| Product Ownership | Owns intellectual property and design | Manufactures to OEM’s specifications |

| Manufacturing Focus | Focuses on innovation | Specializes in high-volume, quality production |

| Economies of Scale | Through market reach and brand | Through shared infrastructure and sourcing |

A Spectrum of Services: From PCB Assembly to Full System Integration

The versatility of electronics contract manufacturing services allows you to choose the level of engagement that suits your project.

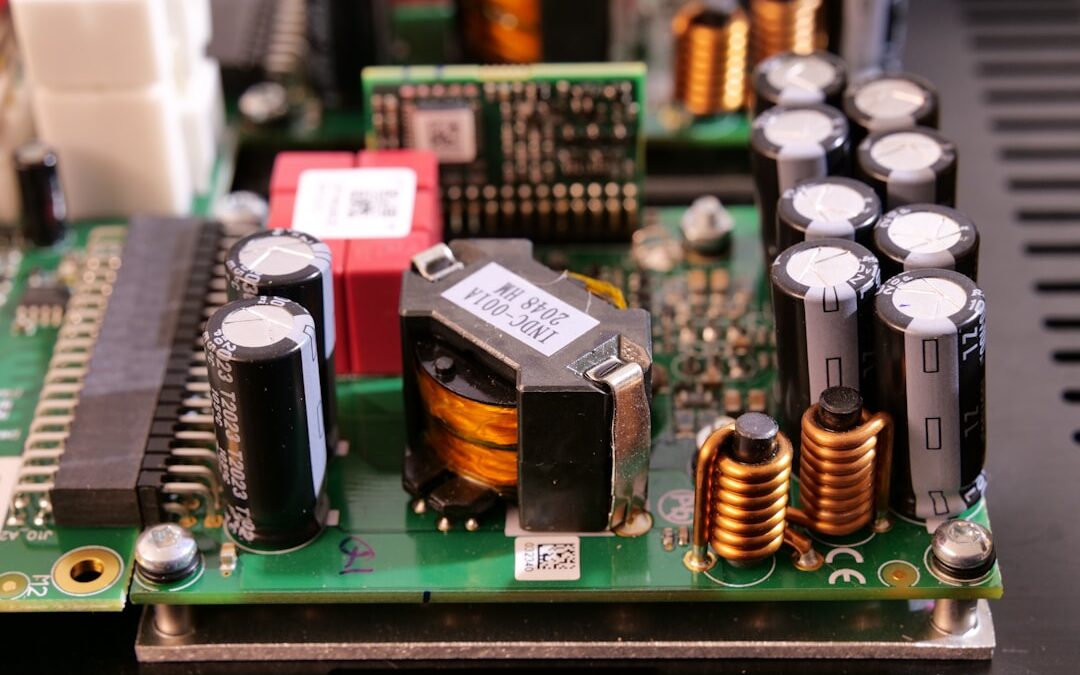

- Printed Circuit Board Assembly (PCBA): The core of most electronic devices. We populate bare PCBs using advanced Surface Mount Technology (SMT) for high-density automated assembly and Through-Hole Technology (THT) for more robust components.

- Prototyping & New Product Introduction (NPI): We offer rapid prototyping to test and validate designs, ensuring a smooth transition from concept to volume manufacturing.

- Box-Build Assembly: This involves the complete assembly of the final product, integrating PCBs into enclosures with wiring, mechanical parts, and sub-assemblies.

- Testing & Inspection: Quality is paramount. We use a variety of methods, including Automated Optical Inspection (AOI), In-Circuit Testing (ICT), and functional testing to ensure every product meets specifications.

- Aftermarket Services: Our support extends beyond production to include repair, refurbishment, and warranty services, maximizing your product’s lifecycle.

The Strategic Advantages of Outsourcing to an EMS Partner

Partnering with an EMS provider is a strategic decision that can significantly boost your business’s success. Clients from startups to Fortune 500 giants reap benefits that propel their products forward.

Key advantages include:

- Cost Savings: Converting fixed overheads into variable costs.

- Faster Time-to-Market: Launching products quicker with our efficient processes.

- Access to Specialized Expertise: Gaining access to advanced technology and skilled professionals.

- Risk Reduction: Mitigating manufacturing and supply chain risks.

- Increased Agility & Scalability: Adapting quickly to market demands.

- Global Supply Chain Access: Benefiting from our established sourcing network.

Cost Implications: Converting Fixed Costs to Variable Savings

A primary benefit of electronics contract manufacturing services is the significant cost advantage. Setting up an in-house facility for complex electronics requires massive capital expenditure (CapEx). By outsourcing to us, you convert these large fixed costs into variable costs, paying only for the manufacturing you need. This reduces CapEx, lowers labor costs through our global manufacturing centers (Mexico, China, Vietnam), and provides access to bulk component pricing. We also manage inventory, minimizing your warehousing costs and the risk of component obsolescence. For more details, explore our Contract Manufacturing Services.

Accelerating Time-to-Market for New Products

In today’s electronics market, speed is critical. We accelerate your time-to-market by providing Design for Manufacturability (DFM) feedback early on, preventing costly delays. With our established infrastructure and rapid prototyping capabilities, you don’t need to build a factory from scratch. This streamlined process allows for faster design iterations and efficient production ramps, giving you a competitive edge.

Accessing Specialized Expertise and Technology

Partnering with us provides immediate access to specialized expertise and cutting-edge technology that would be prohibitively expensive to develop in-house. This includes the latest SMT machines, automated inspection systems, and a team of seasoned engineers. We adhere to rigorous quality standards and hold key industry certifications, saving you the effort. By outsourcing manufacturing, you free up your internal resources to focus on your core competencies: innovation, design, and marketing. Our decades of experience provide invaluable insights for your projects. Learn more about Why Choosing the Right Manufacturing Partner is Critical to Your Business Success.

Navigating the EMS Partnership: From Selection to Supply Chain

Choosing the right partner for electronics contract manufacturing services is a critical strategic decision. It’s about finding an ally who understands your vision and can steer global complexities.

When selecting a partner, consider their:

- Experience and track record in your industry.

- Technological capabilities and quality systems.

- Supply chain expertise and risk management.

- Communication, flexibility, and financial stability.

A thorough vetting process is essential. For more insights, check out our Choosing a Contract Manufacturer Pro Tips.

The Critical Role of Quality Control and Testing

In electronics contract manufacturing services, quality control is the bedrock of reliable products. A single faulty component can have serious consequences, especially in automotive or outdoor products. We embed rigorous quality control and testing throughout our entire process.

We ensure quality by adhering to internationally recognized standards like ISO 9001 and implementing in-process inspections. This includes Automated Optical Inspection (AOI) to scan for assembly defects, In-Circuit Testing (ICT) to check electrical characteristics, and X-ray inspection for hidden solder joints. We also conduct functional testing to verify the product performs to spec and use robust traceability systems to track every component. This commitment means your products are built right the first time. Learn more about our approach to Quality Control.

Managing the Global Supply Chain and Component Sourcing

Managing the complex global electronics supply chain is a core strength of a leading EMS provider. Our approach focuses on ensuring a steady flow of materials, mitigating disruptions, and optimizing costs. We leverage an extensive network of trusted suppliers in Mexico, China, and Vietnam to source high-quality components. We also proactively manage component obsolescence to avoid production halts and handle all logistics, from international shipping to customs clearance. Our Integrated Supply Chain Services and Strong Supplier Relationships provide seamless, end-to-end management.

Mitigating Risks: IP Protection and Navigating Tariffs

Two primary concerns for OEMs are intellectual property (IP) protection and tariffs. We address both head-on. To protect your IP, we use comprehensive Non-Disclosure Agreements (NDAs), secure facilities, and controlled data access, all built on decades of trusted factory relationships.

Navigating the shifting landscape of tariffs and trade policies is another key service. Our expertise in international trade and our presence in key regions—Mexico, China, and Vietnam—allow us to develop effective tariff mitigation strategies. This flexibility enables us to find the lowest landed cost without compromising quality. We closely monitor legal developments, including United States Supreme Court decisions on tariffs, to provide up-to-date advice and adapt our strategies, turning potential risks into manageable challenges.

The Evolution and Future of Electronics Contract Manufacturing Services

The journey of electronics contract manufacturing services reflects the rapid pace of technological innovation. What began as a niche service is now a massive global industry, constantly adapting to new demands. The market’s vigorous growth is fueled by the ever-increasing demand for electronics across all sectors.

A Brief History: From In-House Assembly to Global Outsourcing

The EMS industry began to take shape in the 1960s but exploded in the 1980s and 90s. Originally, OEMs like IBM handled manufacturing in-house. The development of Surface Mount Technology (SMT), which allowed for smaller and more automated assembly, was a key catalyst for change. By the mid-1990s, OEMs realized the cost and efficiency benefits of outsourcing. This led to a massive shift where OEMs sold their factories to EMS providers, creating the international division of labor we see today.

Understanding the EMS Market: Tiers and Segments

The electronics contract manufacturing services market is diverse, with providers categorized into tiers based on annual revenue (from Tier 1 giants with over $5 billion to smaller, specialized Tier 4 firms). The market is also segmented by production type:

- High-Mix Low-Volume (HMLV): Manufacturing a wide variety of products in smaller quantities, common for industrial or medical devices. This requires agility and flexibility.

- High-Volume Low-Mix (HVLM): Manufacturing a few products in very large quantities, typical for consumer electronics. This prioritizes efficiency and automation.

Our firm is adept at navigating these segments, connecting you with the right factory partners for your project’s needs.

Emerging Trends and the Future Outlook for the EMS Industry

The future of EMS is as dynamic as the products it creates. Key emerging trends include:

- Automation and Industry 4.0: Advanced robotics and “smart factories” are increasing efficiency, precision, and responsiveness through AI and real-time data analytics.

- Sustainability: A growing focus on eco-friendly manufacturing, energy efficiency, and reducing e-waste is shaping the industry.

- Miniaturization and Complexity: Components continue to shrink while functionality increases, demanding more precise manufacturing techniques.

- IoT Integration: The expansion of the Internet of Things drives demand for embedded electronics manufacturing across all industries.

- Reshoring and Nearshoring: Geopolitical uncertainty and supply chain concerns are driving a trend toward moving manufacturing closer to home. Our presence in Mexico offers compelling nearshoring solutions for U.S. clients, reducing lead times and increasing resilience.

Core Processes and Industry-Specific Applications

At the heart of electronics contract manufacturing services are refined processes that ensure quality and efficiency. These processes are then customized to meet the exacting demands of various industries, from sensitive automotive sensors to rugged outdoor products.

The Importance of Design for Manufacturability (DFM) and Testability (DFT)

The journey to a successful product begins long before production. Two critical early-stage concepts are key:

- Design for Manufacturability (DFM): This involves optimizing a product’s design to make it easier and more cost-effective to produce. Our engineers work with your team to identify potential issues early, streamlining production and reducing costs.

- Design for Testability (DFT): This focuses on designing the product to be easily and thoroughly tested. Effective DFT leads to more robust quality control, faster testing, and improved product reliability.

By integrating DFM and DFT early on, we help our clients avoid costly redesigns, accelerate time-to-market, and deliver a more reliable product.

How Electronics Contract Manufacturing Services Support Key Industries

The versatility of electronics contract manufacturing services allows us to support a vast array of industries where reliable electronics are critical. We specialize in providing custom solutions for:

- Automotive Electronics: Manufacturing complex and safety-critical components for infotainment, driver-assistance (ADAS), and EV systems that meet stringent automotive standards.

- Sporting Goods Technology: Bringing innovative connected sports equipment and fitness trackers to life with durable and precise components.

- Smart Home Improvement Products: Producing the electronic brains for smart thermostats, lighting, and security systems, ensuring seamless and reliable operation.

- Outdoor Product Electronics: Building durable, high-performing electronics for rugged devices that must endure extreme temperatures, moisture, and impact.

Conclusion: Building Your Product with the Right Partner

As we’ve explored, electronics contract manufacturing services are more than just outsourced assembly. They represent a strategic partnership that offers significant advantages, from converting fixed costs into variable savings to accelerating time-to-market and providing access to specialized expertise.

The complexities of modern electronics, global supply chains, and shifting trade policies demand a sophisticated manufacturing partner. Mitigating risks like IP infringement and navigating tariffs requires a partner with deep experience and trusted relationships across multiple regions.

At Altraco, our decades of experience in offshore manufacturing, combined with strong factory relationships in Mexico, China, and Vietnam, position us as a leader in this field. We simplify global supply chains for our U.S. clients, delivering quality, on-time products with significant cost savings while expertly navigating tariff complexities.

Ready to transform your manufacturing strategy? Learn more about our Contract Manufacturing Services.