New product introduction is the systematic process that transforms your innovative concepts into market-ready products through structured planning, cross-functional collaboration, and strategic execution.

Here’s what you need to know about NPI:

Key Components:

- Define & Plan – Project charter, market research, feasibility studies

- Develop & Prototype – Design refinement, testing, validation

- Validate & Scale – Pilot production, quality control, process optimization

- Launch & Evaluate – Mass production, market introduction, performance review

Core Benefits:

- Reduces development costs and time-to-market

- Minimizes production risks and quality issues

- Ensures manufacturing scalability and efficiency

- Creates alignment across engineering, operations, and commercial teams

The stakes couldn’t be higher. Almost two-thirds of new launches are dead or declining by the end of their second year. The difference between success and failure often comes down to having a robust NPI framework that bridges the gap between brilliant ideas and profitable products.

Whether you’re developing automotive components for global markets or launching innovative outdoor gear, NPI provides the roadmap to steer complex manufacturing decisions, supplier relationships, and quality requirements – especially when working with overseas production partners in countries like Mexico, China, and Vietnam.

I’m Al Brenner, co-owner of a contract manufacturing company with over 40 years of experience helping Fortune 500 companies execute successful new product introduction programs across home improvement, sporting goods, automotive, and outdoor products. Through Altraco, I’ve guided countless brands through the complexities of global manufacturing, from initial concept to market launch.

The Foundations: What is New Product Introduction (NPI)?

At its heart, New Product Introduction (NPI) is a proven, systematic, and repeatable process of taking a product from concept to its final, market-ready form, carried out from the manufacturer’s perspective. It’s the strategic and structured manufacturing journey that brings a new product from an initial concept or idea into a finished, commercially available product. Think of it as the ultimate playbook for launching your next big thing.

While often used interchangeably with New Product Development (NPD), NPI distinguishes itself by focusing specifically on the manufacturing, commercialization, and market launch of a product. It’s about establishing a framework to help organizations turn an initial concept into a finished product efficiently, quickly, and cost-effectively, avoiding the common traps encountered when trying to ramp up and scale production.

The goals of a well-defined NPI process are clear: to improve quality, increase production efficiency, reduce risks, minimize waste, improve speed to market, and ultimately, save money. It’s a cross-functional activity that demands full, active support from upper management across all divisions and departments. Without this collective commitment, even the most brilliant ideas can stumble.

The Core Difference: NPI vs. New Product Development (NPD)

It’s easy to get these two terms mixed up, but understanding their distinction is crucial for a successful launch.

New Product Development (NPD) broadly deals with the entire journey from concept generation, design, and engineering to the commercialization of a new product. It encompasses the creative and technical processes of bringing an idea to life. This includes market research, concept formulation, design, prototyping, and testing.

New Product Introduction (NPI), on the other hand, specifically refers to the strategic and structured manufacturing process of bringing that new product from concept to market launch. It’s the phase where the product moves from a validated design to mass production, distribution, and commercial availability. NPI focuses on manufacturing readiness, supply chain optimization, quality control during production, and the logistics of getting the product into customers’ hands.

While NPD is about creating the product, NPI is about making it ready for the world. Importantly, these aren’t strictly sequential. A cohesive product value management approach often integrates NPD and NPI to occur simultaneously, leveraging a single source of product information and ensuring that manufacturing considerations (like Design for Manufacturability) are baked into the design process from the very beginning.

| Feature | New Product Introduction (NPI) | New Product Development (NPD) |

|---|---|---|

| Focus | Manufacturing, commercialization, market launch, supply chain readiness | Idea generation, design, engineering, prototyping, testing |

| Key Activities | Process validation, production ramp-up, quality control, logistics, market release, post-launch evaluation | Market research, concept development, design, prototyping, engineering, functional testing |

| Primary Goal | Efficiently bring a product to market, optimize production, ensure supply chain readiness | Create a viable, innovative product that meets market needs and company objectives |

| Perspective | Manufacturer’s viewpoint, operational execution | Design, engineering, and marketing/business strategy |

Why a Formal NPI Process is Non-Negotiable

In today’s highly competitive market, companies must develop the right product, at the right time, and at the right cost. Developing and following a robust New Product Introduction process can denote the difference between success and failure.

A formal NPI process is essential for several reasons:

- Competitive Advantage: It enables businesses to improve manufacturing efficiency, lower development costs, accelerate time to market, and improve product quality. This allows us to respond quickly to market changes and outmaneuver competitors.

- Meeting Customer Needs: By integrating customer feedback and market insights throughout the process, we can ensure the product truly resonates with its target audience.

- Increased Revenue and Market Share: Successful NPI leads to products that are well-received, driving sales and expanding our footprint in the market.

- Risk Reduction: A structured NPI process helps proactively identify and manage potential risks during product development and launch phases. This includes everything from design flaws to supply chain disruptions.

- Avoiding Common Traps: Without NPI, teams can fall into common pitfalls like miscommunication, wasted resources on unnecessary prototypes, and costly re-engineering later in the process. The manufacturer, for example, might not have been looped in early enough to inform the team on how to create a product that would be easy to manufacture.

A well-managed NPI program, especially when dealing with complex global supply chains for products like automotive parts or home improvement goods, is crucial. It helps us avoid problems that can arise from inadequate communication or a lack of standardized procedures. We emphasize Proven Tips to Improve Quality in Overseas Manufacturing as part of our NPI strategy, ensuring that quality is maintained regardless of where production takes place.

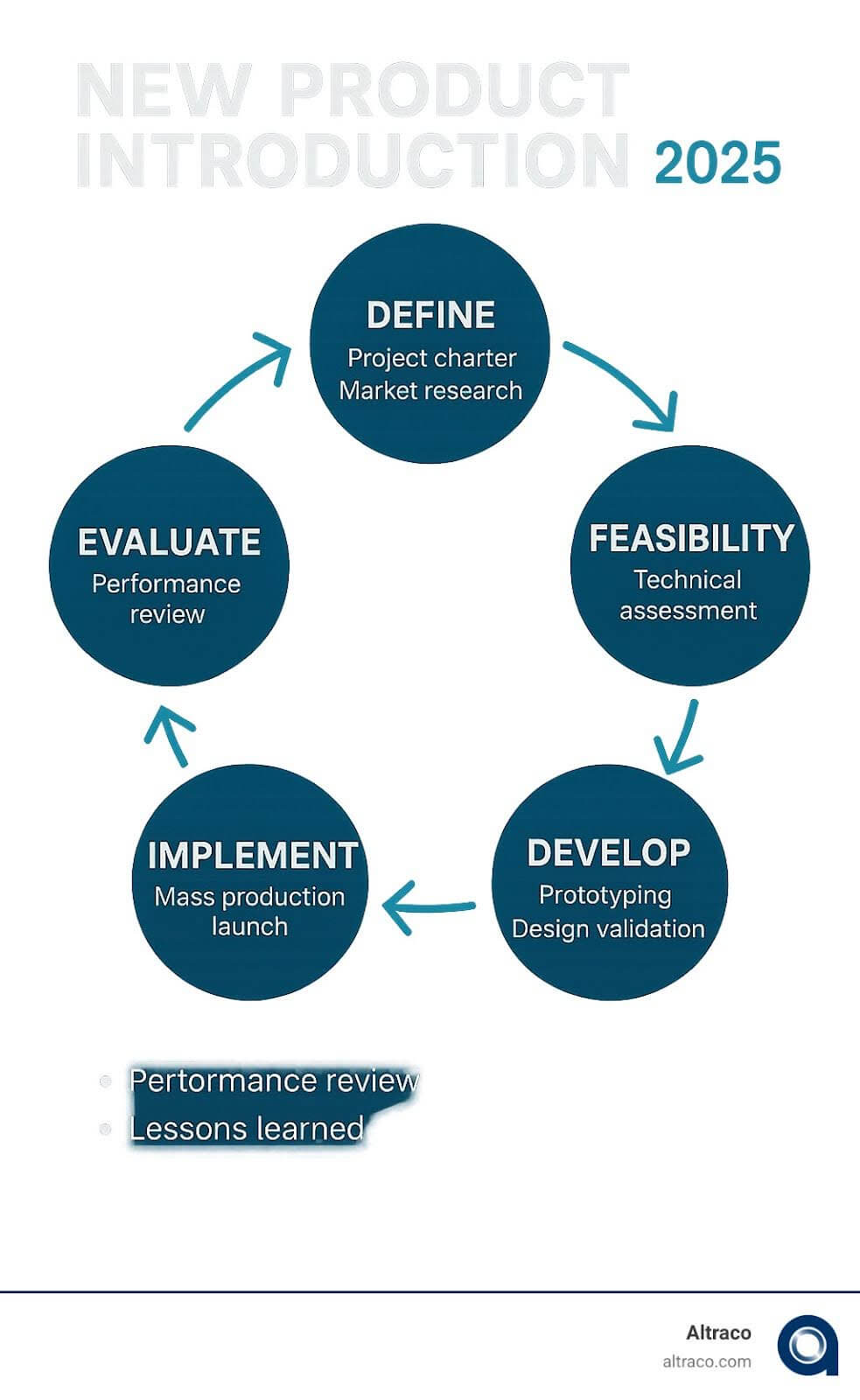

The 6 Key Stages of the NPI Process

The New Product Introduction process is carefully managed by a team of experts who track progress and perform frequent assessments at different stages to ensure the project is moving in the right direction. While the NPI process can vary greatly from organization to organization, a commonly accepted approach defines a series of steps, often operating within a phase-gate system. At the end of each step, the senior management team (and critical stakeholders) makes an up-or-down decision in a formal review, often called a “gate” review.

NPI is not always a linear path. Steps can happen concurrently or influence each other, and the process can be customized for niche or low-volume products, where a more agile approach might be beneficial.

Stage 1: Define & Ideate

This is where the journey begins. It’s about taking that initial “Eureka!” moment and giving it structure. In this stage, we solidify the plan, assemble the NPI team (typically a small, key group of decision-makers to eliminate information silos), and lay the groundwork for success.

Key activities include:

- Project Charter Development: Defining the project’s objectives, scope, budget, and key stakeholders.

- Business Case Creation: Assessing the financial viability and strategic alignment of the new product.

- Voice of Customer (VOC) & Market Research: Gathering insights directly from potential customers and conducting comprehensive market studies to understand demand, existing solutions, competitive landscapes, and customer perceptions. This is the most important step.

- Identifying Stakeholders: Ensuring that representatives from all relevant departments (engineering, marketing, sales, supply chain, quality) are involved from the outset.

- Initial Risk Assessment: Identifying potential challenges and developing preliminary mitigation strategies.

- Defining Goals: Setting clear, measurable goals for the product and the NPI process itself.

The earlier we create our NPI plan, the more efficient the process will be. Starting this process while we still have just a general idea for a new product is the best way to bring that idea to market because we can get the expertise needed to perform every step of the development process correctly.

Stage 2: Feasibility & Planning

Once the idea is defined, we dive deep into whether it’s actually possible – and profitable – to bring it to life. This stage focuses on detailed analysis and strategic planning for manufacturability and the supply chain.

Key activities include:

- Technical Feasibility Assessment: Evaluating if the product can be designed and manufactured to meet specifications. This often involves Design for Manufacturability (DFM) and Design for Assembly (DFA) best practices, where we consider assembly requirements early on.

- Financial Viability Analysis: Refining the business case with more detailed cost projections and potential returns.

- Supply Chain Planning: Identifying potential suppliers, assessing their capabilities, and beginning to build relationships. This is where The Value of Buyer-Supplier Relationships becomes paramount. For our clients, this means tapping into our trusted network of factories in Mexico, China, Vietnam, and other countries.

- Material Forecasting: Estimating the quantity and timing of materials needed for production, a critical step to avoid delays and control costs.

- Production Strategy: Determining the manufacturing approach, whether it’s in-house or outsourced, and planning for tooling, equipment, and facility requirements.

Stage 3: Develop & Prototype

This is the stage where the product truly begins to take physical form. The design is refined, and initial versions are created for testing.

Key activities include:

- Detailed Design: Translating conceptual designs into precise engineering specifications, often using CAD (Computer-Aided Design) software.

- Bill of Materials (BOM) Generation: Creating a comprehensive list of all raw materials, components, and sub-assemblies required to manufacture the product. This is crucial for cost control and procurement.

- Working Prototype Creation: Building initial physical models of the product to test functionality, form, and fit.

- Beta Testing: Testing prototypes with a small group of end-users to gather real-world feedback.

- Engineering Verification Tests (EVT): Rigorous testing to ensure the design meets all engineering and performance specifications.

Our team will waste fewer materials and other valuable resources on unnecessary prototypes or redesigns if the earlier stages are handled diligently.

Stage 4: Validate & Pre-Production

With prototypes developed and initial testing complete, this stage focuses on validating the manufacturing process itself and ensuring the product can be consistently produced at scale while meeting quality standards.

Key activities include:

- Design Freeze: Finalizing the product design, meaning no further changes are made without formal review.

- Tooling and Molds: Developing and refining the necessary molds, dies, and other production tools.

- Pilot Production Run: Conducting a small-scale manufacturing run to test the production line, identify bottlenecks, and refine processes. This helps us ensure that the manufacturer was already looped in from the beginning and informed our team on how to create a product that would be easy to manufacture on a small or large scale.

- Process Validation: Ensuring that the manufacturing process is stable, capable, and repeatable.

- Production Part Approval Process (PPAP): A formal process, especially critical in automotive parts manufacturing, to ensure that a supplier can consistently produce a part that meets customer requirements.

- Quality Control Planning: Developing comprehensive quality control plans and inspection procedures. This includes implementing our Maintain Quality Control Program to ensure consistent quality for products like home improvement goods or sporting equipment manufactured overseas.

Multiple people assessing the project at each stage makes it less likely that a design flaw or another problem with the product will go unnoticed.

Stage 5: Implement & Manufacture

This is the big moment: the product goes into full-scale production and is launched to the market.

Key activities include:

- Mass Production Launch: Ramping up manufacturing to meet anticipated market demand.

- Supply Chain Ramp-up: Ensuring all suppliers are ready and capable of providing materials and components at the required volume and pace. This is where our expertise in managing global supply chains, including those in Mexico, China, and Vietnam, truly shines.

- Ongoing Quality Control Checks: Implementing continuous quality checks throughout the production process to maintain high standards for every batch.

- Logistics and Distribution: Managing the transportation, warehousing, and distribution of the finished product to customers or retailers.

Your team will move from one development step to the next seamlessly, without having to pause to make sure the team is ready to move on. When it comes time to manufacture your product, NPI makes it less likely you’ll have to re-engineer the product.

Stage 6: Evaluate & Improve

The NPI process doesn’t end at launch; it’s a continuous loop. This final stage is crucial for learning and refining for future production runs and subsequent product iterations.

Key activities include:

- Post-Launch Review: Assessing the overall success of the launch against predefined goals.

- Gathering Customer Feedback: Collecting feedback from early customers to identify areas for improvement.

- Analyzing Sales Data: Reviewing sales performance, market adoption, and customer satisfaction metrics.

- Lessons Learned (TGR/TGW): Conducting “Things Gone Right” (TGR) and “Things Gone Wrong” (TGW) exercises to document successes and failures, and identify actionable insights for future projects. This is often the hardest phase for organizations to complete, but it’s vital for continuous improvement.

- Process Refinement: Adjusting manufacturing processes, supply chain strategies, or even product design based on the evaluation findings.

This continuous feedback loop ensures that future new product introductions are even more efficient, cost-effective, and successful.

Assembling Your NPI Success Kit: People, Partners, and Technology

The success of any New Product Introduction hinges on more than just a well-defined process; it requires the right people, strategic partnerships, and enabling technology. An effective NPI program involves a large amount of cross-functional communication and teamwork. The goal is to eliminate information silos and know exactly what each department or individual is doing to move the project forward. NPI is also designed to resolve potential conflicts or disagreements between team members.

Key skills needed for successful NPI include:

- Process Engineering: Optimizing manufacturing workflows and identifying efficiencies.

- Design for Assembly (DFA): Ensuring the product can be easily and cost-effectively assembled.

- Quality Management: Implementing and maintaining stringent quality standards throughout the product lifecycle.

- Supply Chain Management: Overseeing the sourcing, procurement, and logistics of materials and components.

The Role of Technology: QMS and PLM

Digital change has profoundly impacted NPI, making processes more agile, precise, and efficient. Two critical technological pillars are Quality Management Systems (QMS) and Product Lifecycle Management (PLM).

- Quality Management System (QMS): A QMS provides the framework for ensuring product quality and compliance. In NPI, it helps us proactively identify and manage potential risks during product development and launch. It defines procedures for testing, inspection, and corrective actions, ensuring that products, whether they are home improvement tools or outdoor gear, meet all regulatory and performance standards.

- Product Lifecycle Management (PLM): PLM software manages a product’s entire lifecycle, from concept and design through manufacturing, service, and disposal. It provides a centralized repository for all product data, facilitating collaboration across design teams, supply chain partners, and stakeholders.

Integrating QMS with PLM processes is a strategic move to streamline NPI. It allows us to monitor and control product quality throughout its lifecycle, from initial design to production. Leveraging PLM data improves quality management by identifying potential weak points early in the development process, improving overall business efficiency, and enabling real-time data analysis. Cloud-based PLM and QMS technologies further improve agility and efficiency, ensuring all teams communicate throughout the NPI process and follow all rules and regulations.

Leveraging a Contract Manufacturing Partner for Your New Product Introduction

For many businesses, especially those without extensive in-house manufacturing capabilities or global supply chain expertise, partnering with a contract manufacturer is a game-changer for New Product Introduction.

A good contract manufacturer, like us at Altraco, can provide invaluable support at every stage of the NPI process:

- Early Involvement: We can engage from the ideation stage, offering Design for Manufacturability (DFM) support and technical feasibility assessments. This early input can influence design, optimize costs, and prevent costly redesigns later.

- Expertise and Capabilities: We bring decades of experience and specialized knowledge in manufacturing processes, materials, and quality control. This is particularly beneficial for complex products like automotive parts or sporting goods.

- Supply Chain Setup: We have established relationships with trusted factories worldwide, including in Mexico, China, and Vietnam. We can manage material forecasting, procurement, and supplier qualification, ensuring a robust and reliable supply chain.

- Tariff Navigation: Our expertise in navigating complex international trade regulations and tariffs helps clients mitigate risks and achieve significant cost savings. We understand the nuances of global supply chain management.

- Prototyping and Validation: We can accelerate testing with high-quality, functional prototypes and assist with manufacturing process validation.

- Scalability: Whether you need low-volume production for niche outdoor products or large-scale manufacturing for popular home improvement items, we can scale production efficiently.

Choosing a Contract Manufacturer: Pro Tips can make all the difference in your NPI success. Our goal is to simplify global supply chains for our clients, ensuring quality, on-time delivery, and cost-effectiveness.

Common Pitfalls to Avoid in NPI

Even with a robust process, certain missteps can derail a New Product Introduction. We’ve seen these before, and we’re here to help you avoid them:

- Poor Planning: The most obvious reason why you should use a New Product Introduction process is to keep your teams in constant communication and ensure everyone is hitting their deadlines. Failing to establish a clear plan from the outset leads to chaos and delays.

- Inadequate Market Research: Building a product based on assumptions rather than real market needs can lead to low adoption rates. Almost two-thirds of new launches are dead or declining by the end of their second year.

- Lack of Cross-Functional Communication: Information silos cripple NPI. All departments – engineering, marketing, sales, supply chain, quality – must communicate and collaborate seamlessly.

- Ignoring DFM Principles: Not considering manufacturability early in the design phase often leads to costly redesigns, production challenges, and quality issues down the line.

- Insufficient Validation: Rushing through testing and validation phases can result in product failures, recalls, and reputational damage.

- Weak Supplier Management: Unreliable suppliers, poor quality components, or unexpected supply chain disruptions can bring production to a halt. This is why strong buyer-supplier relationships are so vital.

Frequently Asked Questions about New Product Introduction

How early should we start the NPI process?

The New Product Introduction process should begin as early as possible, ideally during the initial concept or ideation stage. It’s never too early to start thinking about NPI. Starting this process while you still have just a general idea for a new product is the best way to bring that idea to market because you can get the expertise you need to perform every step of the development process correctly. Involving manufacturing, quality, and supply chain experts from the start helps create a more robust, cost-effective, and manufacturable design, preventing costly changes later in the product development cycle.

How does NPI function within the supply chain?

NPI is the engine that prepares the entire supply chain for a new product. In the context of supply chain management, NPI involves ensuring that all aspects of the supply chain are prepared to support the launch of the new product, from sourcing and procurement of materials to distribution and delivery to the end customer. This includes qualifying suppliers, forecasting material needs, establishing logistics for components like automotive parts or sporting goods, setting up stringent quality control protocols with overseas factories (whether in Mexico, China, or Vietnam), and ensuring the entire chain can scale to meet production demand. It requires deep collaboration among product development, manufacturing, marketing, planning, and logistics departments.

Can NPI be adapted for smaller, low-volume product launches?

Absolutely. The New Product Introduction framework is scalable and adaptable. For niche or low-volume products, the process can be streamlined with fewer formal gate reviews and a more agile approach. The core principles of planning, validation, and quality control remain critical, but the level of documentation and oversight can be customized to the project’s complexity and risk. Implementing an NPI process is widely recognized as a way of ensuring the launch success of niche volume and highly specialized products, by applying the rigorous processes of high-volume manufacturing to ensure tight control.

Launch with Confidence

The journey from a brilliant idea to a successful product on the market is complex, fraught with challenges, but immensely rewarding. A well-executed New Product Introduction strategy isn’t just a series of tasks; it’s a strategic advantage that allows businesses to innovate, compete, and thrive. By embracing a structured NPI framework, prioritizing meticulous planning, fostering seamless collaboration, and leveraging expert partners, you can dramatically increase your chances of success.

At Altraco, we pride ourselves on simplifying global supply chains and guiding our clients through every step of the NPI process. With decades of experience in offshore manufacturing across home improvement, sporting goods, automotive parts, and outdoor products, we are your trusted partner in bringing your next big idea to market efficiently, cost-effectively, and with uncompromising quality.

Ready to turn your vision into reality? Explore Our Contract Manufacturing Services and find how we can help you launch with confidence.

Al is an entrepreneur, founder, and owner of multiple businesses, including Altraco, an outsourcing and contract manufacturing company. Working across multiple continents and trusted by Fortune 500 companies, Al finds innovative solutions to traditional supply chain challenges. He is a member of Vistage Worldwide.