Why Global Sourcing Matters for Modern Manufacturing

Global sourcing is the practice of procuring goods, materials, components, or services from suppliers located across international borders. Rather than limiting procurement to domestic markets, companies strategically source from international suppliers to optimize costs, access specialized capabilities, improve quality, and build more resilient supply chains.

What you need to know:

- Definition: Purchasing products or services from international markets across geopolitical boundaries

- Primary Goals: Reduce costs, access specialized skills, improve quality, and increase supply chain resilience

- Key Difference: Unlike simple international purchasing, global sourcing is a strategic approach that coordinates procurement across locations and suppliers

- Current Trend: Companies are diversifying suppliers across multiple countries (China, Vietnam, Mexico) rather than relying on single regions

- Modern Focus: Post-pandemic, the emphasis has shifted from pure cost savings to balancing cost with supply chain resilience

The landscape has fundamentally changed. What once was primarily a cost-saving tactic has evolved into a strategic necessity.

In 2025, 57% of companies planned significant changes to their supply chains, with many moving toward a balanced approach—41% of manufacturing facilities are onshore, 22% nearshore, and 37% offshore. The shift reflects hard lessons learned from recent disruptions, including the COVID-19 pandemic and evolving trade policies.

For Fortune 500 companies and large enterprises, the stakes are high. A single supply chain disruption can halt production lines, damage brand reputation, and cost millions in lost revenue. Yet global sourcing, when done right, offers access to lower production costs, specialized manufacturing expertise, and faster time-to-market.

The challenge lies in navigating the complexities—managing tariffs and customs duties, ensuring consistent quality across distant facilities, protecting intellectual property, and coordinating logistics across continents. Recent tariff policies and geopolitical tensions have added another layer of complexity, making expert guidance more valuable than ever.

I’m Albert Brenner, and over 40 years of working with Fortune 500 companies through contract manufacturing, I’ve helped businesses successfully steer global sourcing challenges across China, Mexico, and Vietnam in industries from automotive parts to sporting goods. This guide distills that experience into practical insights for building a resilient, cost-effective global sourcing strategy.

Understanding Global Sourcing: Core Concepts and Definitions

At its heart, global sourcing is a sophisticated procurement strategy where we look beyond our national borders to acquire the goods and services that power our businesses. It’s about using global efficiencies – whether that means leveraging lower labor costs, accessing unique raw materials, or tapping into advanced manufacturing technologies not readily available domestically. This approach allows us to make smarter decisions about where and how we produce our goods.

We understand that the world is interconnected, and so are supply chains. This means we must consider geopolitical boundaries, trade agreements, and varying economic landscapes when making sourcing decisions. By strategically engaging in global sourcing, we can optimize our costs, improve product quality, and even drive innovation. For a deeper dive into procurement strategies, you can explore the various Sourcing & types of sourcing available.

For businesses engaged in contract manufacturing, like us, understanding the nuances of manufacturing terminology in a global context is paramount. It ensures clear communication and consistent quality across diverse production environments. We often help our clients steer complex terms and processes, ensuring their vision translates seamlessly across continents. For more on this, check out our guide on Understanding Manufacturing Terminology in the Global Supply Chain.

Global Sourcing vs. Related Terms

It’s easy to confuse global sourcing with other related terms like international procurement, offshoring, and outsourcing. While they all involve international business, their scope and strategic intent differ significantly. Let’s break them down:

| Term | Scope | Goal | Example |

|---|---|---|---|

| Global Sourcing | Strategic, integrated approach to procurement across international markets | Optimize cost, quality, innovation, and supply chain resilience by tapping a worldwide network of suppliers. | A US-based outdoor products company procures specialized components for its gear from a diverse set of suppliers in Vietnam and Mexico, chosen for their specific material expertise, cost-efficiency, and proximity for different product lines. |

| International Procurement | Broader, transactional process of buying from foreign suppliers | Obtain goods/services from foreign markets; often focuses on individual transactions or specific needs. | A California-based automotive parts distributor purchases a specific type of brake pad from a supplier in Germany because it’s the only one that meets a certain quality standard, without a broader, integrated strategy. |

| Outsourcing | Delegating an entire business process or service to an external vendor | Leverage external expertise, reduce operational costs, or focus on core competencies. Can be domestic or international. | A home improvement brand contracts with an external firm in India to handle its customer service calls or IT support, or partners with us for contract manufacturing of a specific product line, regardless of the factory’s location. |

| Offshoring | Relocating a business process or operation to another country | Primarily driven by lower labor or operational costs in a foreign country. | A US sporting goods company closes its domestic assembly plant and opens its own assembly plant in Mexico to take advantage of lower labor costs and favorable trade agreements, without necessarily sourcing components from that country. |

As you can see, global sourcing is a more strategic and encompassing concept. While our contract manufacturing services often involve elements of outsourcing (delegating production to us) and offshoring (relocating production to countries like Mexico or Vietnam), our focus is on the integrated, strategic approach of global sourcing to find the best partners for our clients worldwide.

The Five Tiers of Global Sourcing

The journey into global sourcing isn’t a single leap; it’s often a progression through different levels of integration and strategic intent. Understanding these tiers can help us assess where our business stands and where we might aim to be:

- Domestic Purchasing Only: At this basic level, all goods and services are procured from suppliers within the home country. While simple, it limits access to global efficiencies and specialized capabilities.

- International Purchasing (Informal): Businesses occasionally purchase from foreign suppliers, often on an ad-hoc basis, perhaps for a unique component or a one-off project. There’s no formal strategy or integration.

- International Procurement (Formalized): Here, foreign procurement becomes a more regular part of the business, with established processes for identifying and managing international suppliers. It’s often driven by specific cost savings or access to particular resources.

- Centralized Procurement Across Locations: This tier involves coordinating procurement activities across various business units or international offices. The goal is to leverage economies of scale and standardize processes globally, even if suppliers are still managed somewhat independently.

- Integrated Global Sourcing Strategy: This is the pinnacle. Domestic and international vendors are treated equally within a unified, strategic framework. Decisions are made based on optimizing the entire supply chain for cost, quality, innovation, and resilience, with global coordination and real-time data informing every move. This is where we aim to operate, helping our clients achieve this level of sophistication.

The Strategic Benefits of a Global Production Strategy

Embracing a global production strategy offers a treasure trove of benefits that can significantly boost a business’s competitive edge and operational efficiency. It’s not just about finding a cheaper deal; it’s about making smarter, more strategic choices that impact our bottom line and our ability to innovate.

One of the most compelling advantages is cost reduction. Many regions worldwide offer lower labor costs and more affordable raw materials compared to domestic markets. For instance, we see significant savings when manufacturing outdoor products or home improvement items in countries like Vietnam or Mexico, where labor costs are often more competitive. This allows us to pass those savings on to our clients, making their products more accessible and profitable. The ability to source Why Bulk Natural Materials Are Changing Modern Manufacturing globally further improves this cost advantage.

Beyond cost, global sourcing allows us to tap into specialized skills and technology. Different countries excel in different industries. For example, Mexico has become a hub for sophisticated automotive parts manufacturing, while Vietnam is renowned for its electronics and certain types of sporting goods. By partnering with manufacturers in these regions, we gain access to expertise, machinery, and production techniques that might be scarce or prohibitively expensive elsewhere.

This strategic approach also opens doors to market expansion opportunities. By establishing sourcing relationships in a foreign country, we gain valuable insights into that market, potentially paving the way for future sales or distribution channels. It also facilitates improved scalability. When demand for a product surges, having a global network of contract manufacturers allows us to ramp up production quickly and efficiently, without being constrained by domestic capacity. This ability to scale rapidly is a game-changer for growing businesses. Our Global Production Strategy often involves identifying these scalable opportunities for our clients.

Imagine a scenario where we’re sourcing specialized automotive parts from Mexico’s manufacturing hubs. This isn’t just about cost; it’s about tapping into a highly skilled workforce and advanced facilities dedicated to precision engineering, ensuring the quality and performance our clients expect.

Gaining a Competitive Edge

In today’s market, a truly effective global sourcing strategy is about more than just reducing expenses; it’s about gaining a competitive edge. By looking globally, we open up pathways to innovation, faster time-to-market, and the ability to capitalize on dynamic emerging markets.

Accessing innovation is a huge plus. Our global partners often bring fresh perspectives, new materials, and advanced manufacturing processes to the table. This collaborative environment can lead to significant product improvements for items like sporting goods or outdoor equipment, keeping our clients ahead of the curve.

Furthermore, global sourcing can significantly contribute to a faster time-to-market. By optimizing production locations and leveraging efficient global logistics, we can reduce lead times from design to delivery. This agility is crucial, especially in industries where trends shift quickly.

We’ve seen how benefiting from emerging markets can transform a business. Take, for instance, the remarkable growth in Vietnam’s electronics manufacturing. New free trade agreements and a burgeoning industrial base have created a fertile ground for sourcing high-quality components and finished goods at competitive prices. Similarly, Why Mexico Manufacturing Is Changing Global Supply Chains highlights how our neighbors to the south are becoming increasingly vital for manufacturing, especially for products destined for the US market.

Consider a sporting goods company that leverages a Vietnamese Contract Manufacturer for advanced composites used in high-performance equipment. This partnership not only provides access to specialized materials and expertise but also positions the company to quickly adapt to new design innovations and market demands, securing a distinct advantage over competitors. It’s about being smart, agile, and globally connected.

Navigating the Challenges and Risks of Global Sourcing

While the benefits of global sourcing are substantial, it’s not without its problems. Like any grand adventure, it comes with challenges and risks that require careful planning and expert navigation. We’ve certainly seen our share of complexities over the years.

One of the most prominent challenges is geopolitical instability. Recent global events, from the COVID-19 pandemic to various geopolitical shifts, have highlighted the fragility of global supply chains. A reliance on a single region for critical components, for example, can lead to unforeseen disruptions, impacting business continuity. This is precisely why we often discuss Supply Chain Globalization: Is It Worth the Risk? with our clients, emphasizing diversification.

Logistical complexity and lead times are another significant consideration. Moving goods across oceans and continents involves intricate coordination, potential delays, and higher transportation costs. Longer lead times can tie up working capital and make it harder to respond quickly to market changes.

Ensuring quality control consistency from a distance can also be tricky. How do you maintain the high standards our clients expect for their automotive parts or outdoor products when production is thousands of miles away? This requires rigorous processes, clear communication, and often, on-the-ground presence. For practical advice on this, our guide on Proven Tips to Manage Quality Issues in Manufacturing is a great resource.

Finally, intellectual property (IP) protection is a critical concern, especially when partnering with manufacturers in certain regions. Safeguarding designs, patents, and proprietary information requires robust legal agreements and careful due diligence. This is a topic we take very seriously, particularly when advising clients on How to Partner with Chinese Manufacturers.

Managing Hidden Costs and Tariffs

Beyond the obvious unit price, global sourcing often involves a host of “hidden costs” that can surprise the unprepared. We always emphasize a thorough total landed cost calculation, which includes not just the product cost, but also transportation and insurance, customs duties, taxes, handling fees, and even the cost of potential rework or communication errors.

Currency exchange rate volatility is another factor that can significantly impact costs. A strong US dollar, like the one we saw at an all-time high in 2023, can make foreign purchases more appealing by increasing our purchasing power. However, unfavorable fluctuations can quickly erode planned savings. We advise our clients to consider financial hedging strategies to mitigate these risks.

Then there are the customs duties and fees, a labyrinth of regulations that can be daunting. Navigating US Tariffs, including understanding specific policies like the Section 301 Tariffs on goods from China, is crucial. This is an area where our expertise truly shines. We stay on top of the latest developments, including any implications from US Supreme Court decisions regarding tariffs, to help our clients understand their financial exposure and optimize their sourcing strategy. Our guide on Outsourced Manufacturing: The Guide to Navigating US Tariffs and the China Tariffs: Complete Guide are invaluable resources for clients facing these complexities. About half of companies pass the full increase of tariffs to customers, highlighting the direct impact on profitability and consumer prices.

Overcoming Cultural and Regulatory Problems

One of the trickier aspects of global sourcing is navigating the subtle yet significant differences in culture and regulation. It’s not just about translating words; it’s about understanding context, unspoken rules, and varying legal frameworks.

Language barriers are the most obvious hurdle, but even with fluent translators, nuances can be lost. We’ve learned that understanding different business etiquette and negotiating across cultures requires patience, respect, and a willingness to adapt. What might be considered direct and efficient in one culture could be seen as rude or aggressive in another. Building strong, trusting relationships with our manufacturing partners is key, and this often means investing time in cultural intelligence. Our focus on The Value of Buyer-Supplier Relationships helps bridge these gaps.

Equally important are the varying legal and regulatory standards. Each country has its own set of labor laws, environmental regulations, export/import restrictions, and anti-corruption statutes. We must ensure our sourcing initiatives are fully compliant with both the local laws of the manufacturing country (like Mexico or Vietnam) and the international regulations relevant to our clients in California and beyond. This calls for meticulous due diligence and often, the involvement of legal and compliance experts to ensure everything is above board.

Building a Resilient and Modern Strategy

The world has changed, and so has global sourcing. The days of blindly chasing the lowest price are over, replaced by a strategic imperative to build resilience into our supply chains. The post-COVID supply chain evolution has driven a fundamental shift from a “just-in-time” mentality, which prioritized lean inventories and cost efficiency, to a “just-in-case” approach that emphasizes redundancy, flexibility, and the ability to withstand disruptions.

This shift is reflected in recent trends. According to a 2025 survey, more than 9 in 10 US executives stressed the importance of diversifying manufacturing and supply chains, and diversifying suppliers was cited as their top business continuity strategy. This means proactively spreading production across multiple regions rather than concentrating it in one.

We’re seeing a clear trend towards nearshoring and regionalization. While offshore operations still play a vital role, there’s a growing movement to bring manufacturing closer to home. In the coming three years, onshore operations are expected to rise to 48%, nearshoring to 24%, and offshoring is projected to drop to 28%. This is particularly relevant for us, as it highlights the strategic importance of our contract manufacturing capabilities in Mexico Manufacturing and Vietnam Manufacturing California. These locations offer compelling advantages in terms of reduced lead times, lower shipping costs, and often, more stable geopolitical environments for products destined for the US market.

It’s all about building supply chain resilience. This means designing a supply network that can absorb shocks, adapt to changing market conditions, and continue delivering value even when unforeseen events strike. It’s a proactive, strategic endeavor that safeguards our clients’ businesses.

Best Practices for Effective Global Sourcing Management

To truly succeed in global sourcing, we’ve identified several best practices that serve as our guiding principles. These aren’t just theoretical; they’re strategies we implement daily for our clients in home improvement, sporting goods, automotive parts, and outdoor products.

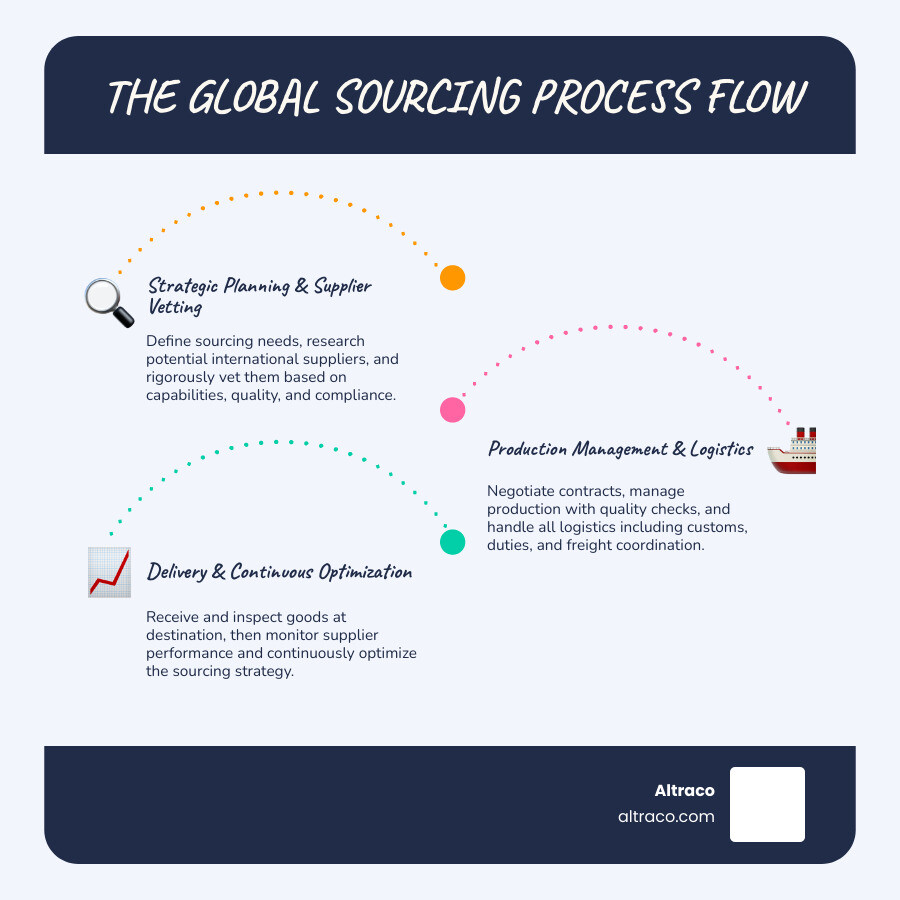

First, it’s crucial to align sourcing with business objectives. Is the goal purely cost reduction, or is it also about innovation, speed, or market entry? This clarity guides all subsequent decisions. Second, thorough supplier vetting is non-negotiable. We conduct deep dives into potential partners’ capabilities, financial stability, ethical practices, and compliance records. This due diligence is critical for a successful partnership. For more insights into this process, read our Choosing a Contract Manufacturer: Pro Tips.

Third, establishing strong partnerships is paramount. Global sourcing is not just transactional; it’s relational. We foster open communication, trust, and mutual understanding with our factory partners. These Strong Supplier Relationships are the bedrock of consistent quality and reliability. Fourth, implementing supplier scorecards allows us to objectively measure and monitor performance. These scorecards track key metrics like on-time delivery, quality, responsiveness, and compliance. Our Supplier Scorecards: Complete Guide details how we use these tools.

Finally, continuous performance monitoring and strategy review are essential. The global landscape is dynamic, so our sourcing strategies must be too. We regularly review performance, adapt to market changes, and refine our approach to ensure ongoing success and resilience for our clients.

The Role of Technology in Modern Global Sourcing

In the complex world of global sourcing, technology isn’t just an aid; it’s a game-changer. Modern tools transform what used to be a fragmented, manual process into a streamlined, data-driven operation. We leverage these advancements to provide our clients with unparalleled visibility and efficiency.

Enterprise Resource Planning (ERP) systems are the backbone of this technological integration. They consolidate data across all business functions—from procurement and inventory to finance and logistics—providing a single source of truth. This allows for more accurate demand forecasting and better resource allocation.

AI and machine learning are revolutionizing how we predict demand, identify potential disruptions, and even select suppliers. These intelligent systems can analyze vast datasets to uncover patterns and make recommendations that human analysis might miss. For example, AI can help us anticipate supply shortages for automotive parts or optimize inventory levels for outdoor products.

Supplier Relationship Management (SRM) software facilitates stronger, more transparent relationships with our contract manufacturers. It helps track communications, manage contracts, monitor performance, and ensure compliance, fostering collaboration across different time zones and cultures.

Blockchain for supply chain transparency offers an immutable record of transactions and movements, enhancing trust and traceability from raw materials to finished goods. This is particularly valuable for verifying ethical sourcing and product authenticity.

These technologies create real-time visibility platforms. We can track shipments, monitor production milestones, and react swiftly to any issues, minimizing delays and mitigating risks. This comprehensive, tech-driven approach is a core component of our Integrated Supply Chain Services, ensuring our clients always have their finger on the pulse of their global operations.

Frequently Asked Questions about Global Sourcing

We often get asked similar questions about global sourcing. Here are some of the most common ones, along with our insights:

What is a real-world example of global sourcing?

Let’s imagine an American home improvement brand that wants to produce a new line of power tools. To optimize costs, tariffs, and proximity to the US market, they partner with us as their Contract Manufacturer. We might help them source specialized electronic components from a trusted supplier in China, leverage a facility in Vietnam for the intricate motor assembly due to its precision manufacturing capabilities, and then use a factory in Mexico for final assembly and packaging. This strategy allows them to tap into specific regional strengths, steer tariffs effectively, and reduce lead times for distribution to the US market.

How does global sourcing impact supply chain resilience?

The impact can be two-fold. If a company becomes over-reliant on a single country or supplier through global sourcing, it can significantly increase risk, as seen during the COVID-19 pandemic when many businesses faced severe disruptions from factory shutdowns in specific regions. However, a modern, well-executed and diversified global sourcing strategy significantly improves resilience. By multi-sourcing from different regions—for example, having alternative suppliers in China, Vietnam, and Mexico—businesses can mitigate risks against geopolitical shifts, economic downturns, and logistical disruptions. This strategic diversification ensures that if one part of the supply chain falters, others can step in, maintaining continuity.

Is global sourcing only about finding the cheapest price?

Absolutely not! While cost savings are often a major initial driver and a significant benefit of global sourcing, modern strategic sourcing goes far beyond just chasing the lowest price. It’s about balancing cost against other critical factors such as:

- Product Quality: Accessing manufacturers with superior expertise or technology.

- Access to Innovation: Partnering with suppliers who can offer new designs, materials, or manufacturing processes.

- Speed-to-Market: Leveraging efficient production and logistics to get products to consumers faster.

- Supply Chain Resilience: Building redundancy and flexibility into the supply chain to withstand disruptions.

- Access to Specialized Skills: Tapping into unique craftsmanship or technical expertise.

A truly effective global sourcing strategy optimizes for total value, considering all these elements to create a sustainable competitive advantage, not just short-term cost reductions.

Conclusion

As we’ve explored, global sourcing has evolved dramatically. What began as a simple quest for cost reduction has matured into a complex, strategic imperative for building a competitive and resilient business. It’s about intelligently leveraging global resources to optimize every aspect of our supply chain, from cost and quality to innovation and agility.

The key takeaway is clear: success in global sourcing demands careful planning, robust risk management, and the cultivation of strong, transparent supplier partnerships. Without these pillars, the potential pitfalls—from hidden costs and tariffs to geopolitical instability and quality control issues—can quickly outweigh the benefits.

Navigating the complexities of international manufacturing is challenging, which is why partnering with an experienced guide can streamline the entire process from supplier selection to tariff management. We bring decades of expertise in contract manufacturing across regions like China, Mexico, and Vietnam, helping our clients in home improvement, sporting goods, automotive parts, and outdoor products achieve their global sourcing goals with confidence.

Learn more about our International Sourcing Services and find how we can help you build a more efficient, resilient, and profitable global supply chain.