Regardless of your stance on their impact, tariffs are a consistent factor in US trade relations and a significant piece of the puzzle when it comes to supply chain management.

While managing trade compliance in your business, there are a variety of strategies to consider when navigating tariffs. One may solve for lower costs, another may solve for managing risks, while others may seek a balance of both.

Impact of Tariffs

As if there isn’t enough to worry about in your role—always seeking lower costs while managing too many suppliers—external challenges can quickly disrupt your productivity, and tariffs move quickly to the top of the list.

Whether you have an internal team that handles trade compliance, or it falls on you when these issues arise, trying to find good resources to help is yet another demand on time you’d rather not have.

As you evaluate tariffs, what challenges do you face?

- Margin pressure

- Management pressure

- Share price pressure

- Inventory forecasting and purchasing instability

- Supplier failure

- Production relocation risk

- And more

The tactics you use to navigate trade compliance can have a major impact on your overall supply chain strategy in both the short and long term as you look to manage risk and preserve the lowest possible cost.

Recent History of Tariffs

The history of tariffs is an important part of the conversation as we consider how it will impact overseas manufacturing now and in the coming years. The last hundred years have included politicians vacillating about tariffs, and, despite examples of tariffs doing harm, they continue to be a consistent piece of foreign trade policy. As such, they remain a supply chain variable that requires a plan to handle them well.

In an attempt to mitigate the economic impact of the Great Depression, the Smoot-Hawley Tariff Act went into effect in 1930, imposing high duties on imported goods. To this day, the effects of this tariff on the Great Depression are disputed, but it set the tone for the use of aggressive tariffs when faced with economic challenges.

Imports at major US retail container ports increased 13.6% in October 2018 as tariffs on $200 billion worth of Chinese goods were on the horizon.

Later, the Reciprocal Tariff Act of 1934 authorized the executive branch to negotiate tariff reduction agreements with other countries, giving the president more control over tariffs in regard to foreign relations. Up until this point, the legislative branch had controlled tariffs through legislation.

The frequent use of high tariffs during this time led to the formation of the General Agreement on Tariffs and Trade (GATT) in 1947, a legal agreement between multiple countries focused on lowering trade barriers, including tariffs. Since its inception and reformation as the World Trade Organization (WTO), countries in the organization have seen dramatic tariff reduction with other member countries.

Another major impact came with the Trade Act of 1974. This act gave the president even more power over tariffs and foreign trade agreements. It allowed the president to quickly create tariffs through investigations into potential threats to US economic and trade interests. Multiple presidents have used the provisions from this act over the years as they work to protect US interests.

Only 1% of American companies considered moving their production back to the US.

Most recently, Section 301 of the Trade Act of 1974 has been the justification for the tariffs under President Trump. These tariffs were imposed on China after an investigation determined “the acts, policies, and practices of the Chinese government related to technology transfer, intellectual property, and innovation are unreasonable or discriminatory and burden or restrict U.S. commerce.” Because of these tariffs on China and those recently placed on aluminum and steel, past debates on the benefits and challenges of tariffs have resurfaced.

With such a varied past, the future of tariffs and trade compliance is still unknown—yet we can be confident it will continue to be an important challenge for a company’s supply chain strategy.

Effective Ways to Navigate Tariffs

As tariffs remain a consistent factor in sourcing and overseas manufacturing, it’s important to continually reevaluate your strategy to find the optimal solution to manage risk while keeping costs low. Not every strategy will be best for every business, but considering all strategies will help you create a tariff plan that is best for you.

1) File or Research Tariff Exclusions

One method to avoid tariffs is to file for an exclusion. These exclusions are based on criteria such as whether you can find the product domestically or if you can verify it would be no threat to national security. Once the tariff has been announced, there is a specific period during which companies can file exemptions to the tariff. These exemptions are reviewed by the government agency behind the tariff and publicly announced at a later date.

Dependent on the specific tariff, some exclusions apply to all products of that nature, regardless of the company, while some only apply to the company who filed for the exemption. For the tariffs with non-exclusive exemptions, such as the Section 301 tariffs on China, a good place to look is the exclusion list.

Tariff Exemption Process

In September 2018, the process for determining exclusions shifted slightly by allowing filing companies the opportunity to share a rebuttal to any objections made against their request. It also allowed for more online resources to help submit and determine exclusions.

How to Apply for Tariff Exemption

While the specifics vary based on the tariff, it typically follows this format:

- Companies file a petition for an exemption of their specific product or for a general exclusion of the product with the appropriate government organization (often the US Department of Commerce, the Bureau of Industry and Security, or the US Trade Representative).

- In many cases, other companies are allowed to object to the exclusions that have been requested, with the original requestor being able to offer a rebuttal.

- With some tariffs, such as the Section 301 tariffs, any exclusions apply to all companies importing similar products.

- The most recent tariffs and duties use an online site for exclusion requests. There are deadlines to submit exclusion requests for each tariff, with public lists of exclusions published at a later date.

2) Update Product Designs

Another option is to make adjustments to your product design. Evaluate the parts you use to see if the design could be reworked in a way that might allow you to meet different tariff classifications. Work with your supplier to analyze your design and understand the materials and complexity to produce the product. Your supplier might be able to give you different options to keep your costs low through updated designs, removing it from the impact of additional tariffs.

Working with a partner can help you find reliable factories, manage logistics and infrastructure, and provide specific insight about that country so you can quickly adjust your strategy.

3) Raise Prices for Your Customers

Ultimately, most companies cannot or will not absorb the entire cost imposed by high tariffs and will pass some, if not most, of the cost on to their consumers. This is often a realistic short-term option to mitigate the increases, but it must be done with caution and at the correct time. Increasing your prices while your competitors’ prices remain low can be harmful to both your profit and brand. This is typically the best option when tariffs are imposed on consumer goods—the recent tariffs on China and on steel and aluminum have caused large brands like Walmart and Coca-Cola to announce an increase in prices.

4) Move Sourcing or Manufacturing to Another Country

As tariff conversations continue to be in the spotlight, some companies are beginning to explore alternatives to source their products impacted by tariffs. For example, with the Section 301 tariffs focused on China, some companies look to move their production to other countries like Vietnam, India, or Mexico. While it might be a big leap, this can be a good alternative strategy that helps mitigate long-term risks that come by having all of your manufacturing in one country. It just means asking good questions and making quick but skillful decisions.

Start by analyzing if it’s possible to find a new supplier based on product resources or the labor skills to manufacture your products.

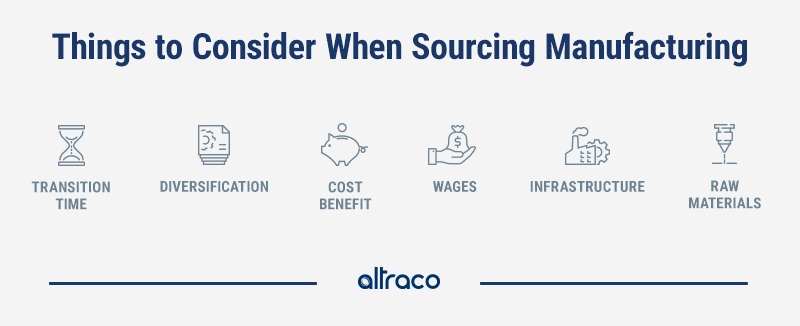

Then you can begin to consider some of the other factors:

- Transition time: Can you afford the time it takes to find new suppliers and get them up to speed to manufacture your products?

- Diversification: Is diversification a beneficial long-term strategy for your company?

- Cost-benefit: Is a transition to a new supplier worth the cost?

- Wages: With increased wages in some countries, will a move be worth it in the long run?

- Infrastructure: Will the current infrastructure hinder your ability to do business?

- Raw materials: Where do you source your raw materials?

- What other factors do you need to consider? Logistics? Political stability? Exchange rates?

Note: Many of these factors can be managed or altogether avoided by working with an established partner who has existing relationships in those countries.

Working with a partner can help you find reliable factories, manage logistics and infrastructure, and provide specific insight about that country so you can quickly adjust your strategy. This allows you to save both time and money by minimizing the interruption of your supply chain. This type of diversification can provide a good alternative during trade wars and can also mitigate future risk. With the right partner who has the right relationships, it can be a viable solution without dramatically impacting your company’s supply chain.

Harmful Ways to Navigate Tariffs

Simply put, there is no one-size-fits-all solution for tariffs. But be careful—there are some strategies that may seem like a quick fix but can have a negative impact on you and your business in the long run.

Transshipment to Avoid Tariffs

As an alternative to navigating and correctly handling tariffs, some importers believe they can avoid tariffs altogether through transshipment. By first moving their products to another country, whether in Asia (such as Vietnam, India) or in North America (like Canada), the country of origin changes before sending the goods to the US. However, this option is illegal and the US government continues to crack down on transshipping, with even more force with recent tariffs.

If your parts, subassemblies or finished products are on the list of affected items, there is no way to legally avoid paying the tariffs when you import into the US.

The tactics you use to navigate trade compliance can have a major impact on your overall supply chain strategy.

With recent tariffs, there have been accounts of overseas suppliers telling their US companies that transshipment is legal and working with them to move products so they are labeled with a different country of origin. Often, this is just an attempt to maintain the demand of goods for the factory and does not make it a legitimate, legal option for handling tariffs. While avoiding and managing tariffs is a difficult pill to swallow, that doesn’t mean it’s worth the consequences of trying to cut corners.

Reclassifying Your Products

Another (illegal) method used to avoid tariffs is product reclassification. This involves incorrectly classifying your product to avoid the tariff completely. In cases where there may be a legitimate reason for reclassification, a claim may be submitted to US Customs and Border Protection. However, some companies will reclassify their products on their own in an attempt to avoid tariffs—incorrectly classified imported products can lead to both civil and criminal penalties according to US Customs. Reclassification, though it might seem like a valid short-term option, is not the ideal way to manage tariffs safely and sustainably.

Getting Around Tariffs for Your Business

No matter what strategy your business chooses to navigate tariffs, preparation and relationships are key.

Even when reacting to current tariffs, start by analyzing all possibilities—both for the short and long term. This will help you to see all possible scenarios, keeping your costs low and future risk managed. Then continue to reinforce supplier relationships. These relationships can be a great resource as you look for new options to save costs and best handle tariffs.

Al is an entrepreneur, founder, and owner of multiple businesses, including Altraco, an outsourcing and contract manufacturing company. Working across multiple continents and trusted by Fortune 500 companies, Al finds innovative solutions to traditional supply chain challenges. He is a member of Vistage Worldwide.