Quality issues in manufacturing are just plain annoying. Why can’t the factories follow the drawings, properly inspect the goods, properly verify that the quantities match the PO and deliver the pallets on-time? It is not that hard—why don’t they get it right? Why don’t they seem to appreciate defects, improper quantities, and late deliveries that causes us to lose money, time, and company image?

How do you handle those issues with your suppliers and stop the frustration?

Let’s explore a few proven tips to improve (or even solve) these problems.

Tip 1: Expect and Plan for Quality Issues Before Production Starts

The best quality control happens before you release your purchase order, even if it’s a small run. Intentionality and specificity can make a world of difference in quality control.

To start, what are your first impressions? Here is a list to get started:

- Meet the plant manager(s) in person: are they on-time, professionally dressed, courteous and respectful?

- Inspect the factory: is the facility clean, organized and does it have segregated area(s) for rejected goods?

- Review their operating procedures: where are inspection tools stored, how often are they calibrated and by whom?

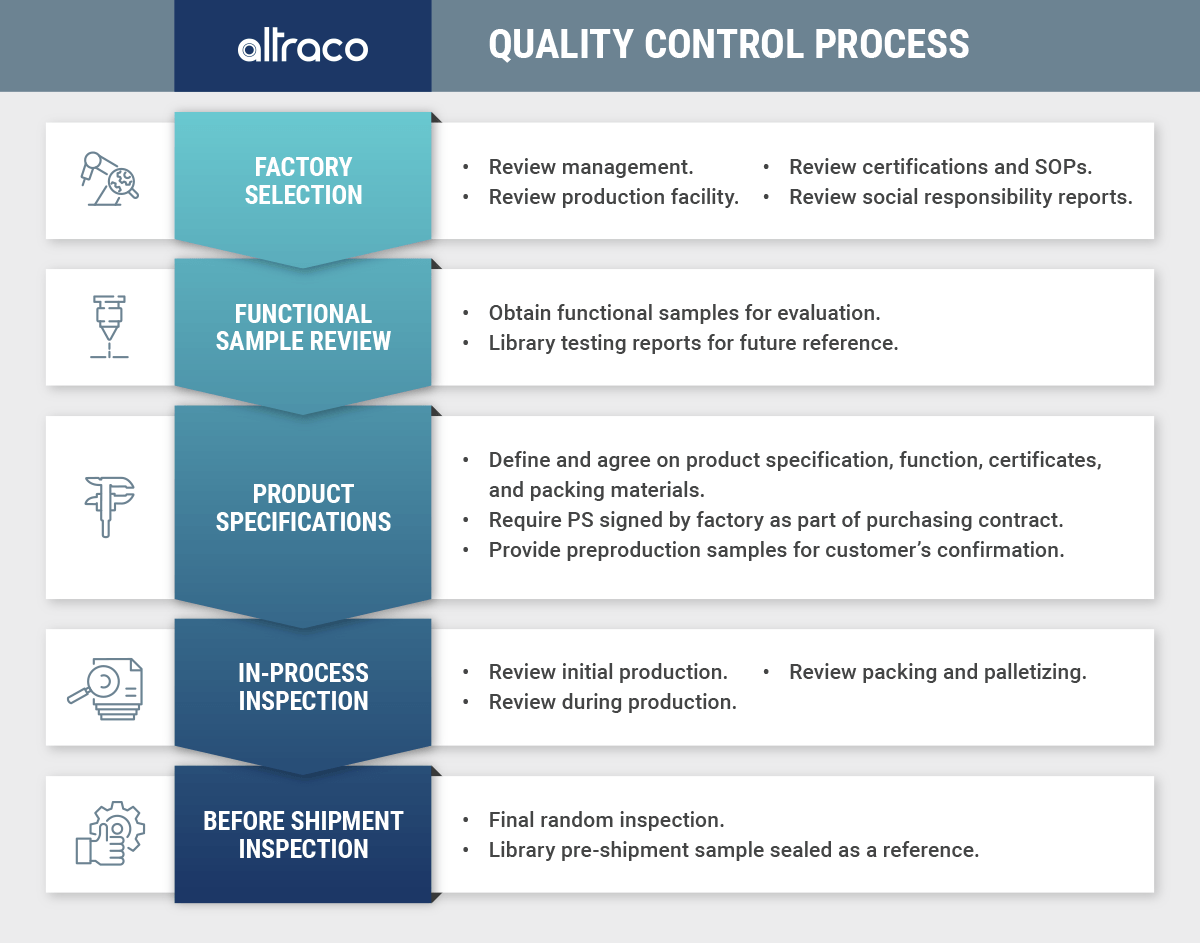

Note: If you don’t have a quality control program, that’s the first step. Determine internally how you plan to verify the quality of your products. Here’s an example of how we manage this at Altraco:

Next, it’s crucial to prepare a supplier agreement so all parties have the same expectations. This includes who and how each will be held accountable for issues. Make sure your agreement does the following:

- Outlines culture and goals. State how both parties make money and how both parties are hurt when failures occur.

- Discusses frequency of inspections, such as after first articles, production set-up, during production, packing, etc.

- Includes a factory scorecard.

A single, final inspection isn’t enough. It is so much easier and less expensive to prevent problems rather than fixing problems.

Tip 2: Outline What Will Happen When Issues Arise

Even with these measures in place, there will be times when issues occur.

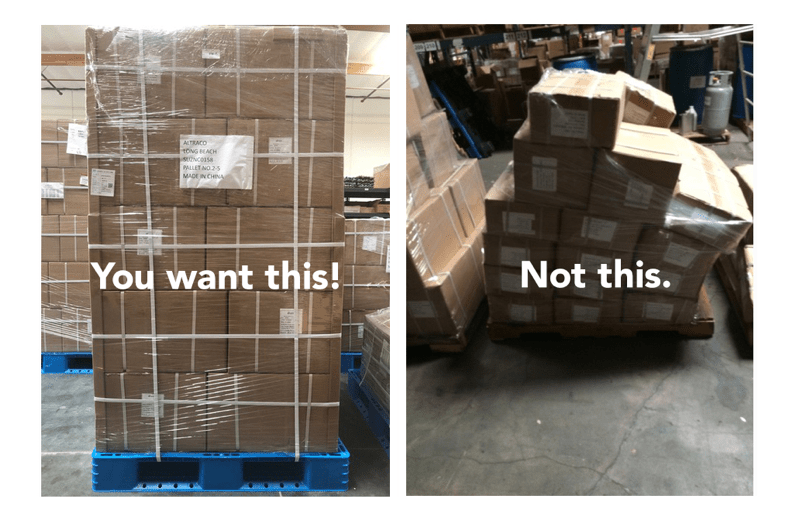

What if you get a palette that looks like this?

Nobody wants to be on the receiving end of this! But what if it does happen? The way you handle these issues can help or hurt your relationship with your supplier.

- Be direct and communicate quickly.

As soon as you realize there is a quality issue in manufacturing your products, communicate this to your supplier. There might be a simple solution. You can find this by talking it through as soon as you encounter the issue. Then provide them with the specifics and work together to find a solution.

- Offer potential solutions.

While it might not seem like your responsibility, it can be helpful in the relationship with your supplier to offer potential solutions.

What might seem like simple fix may be something they hadn’t even considered. Think outside the box and do what you can to make their job even easier. It can be a good opportunity to invest in the long-term relationship building with your supplier. Remain realistic about your solutions though.

- Look at things from the supplier’s point of view.

Many overseas manufacturers have low margins on their goods. Make note of the impact that any potential improvements might have on your manufacturer’s bottom line. Try to see the issue from their point of view. Take the time to share inspection results with your suppliers so they can improve their processes in the future.

- Reference the supplier agreement.

- Has this issue been anticipated?

- What can be learned?

- How can this issue be avoided in the future?

- Should the supplier agreement be amended?

While empathy is important, it doesn’t mean you should shy away from keeping an internal record of quality incidents. Tracking supplier quality can help you make future decisions about supplier consolidation or expansion.

Whether this is an internal record or a scorecard shared with your supplier, consolidating this information can help set expectations between buyers and suppliers, increase transparency, and provide direction in the future.

Tip 3: Continue to Build the Partnership

The goal is good communication and continuous improvement, even when quality issues in manufacturing arise. If you’ve found a good overseas manufacturing partner, they will want to improve.

Invest in the relationship through extreme clarity, communication, and consistent accountability.

“Continuous improvement is built, not on confrontation, but partnership, cooperation, and collaboration.” – Chuck Intrieri

Al is an entrepreneur, founder, and owner of multiple businesses, including Altraco, an outsourcing and contract manufacturing company. Working across multiple continents and trusted by Fortune 500 companies, Al finds innovative solutions to traditional supply chain challenges. He is a member of Vistage Worldwide.