As an organization looks to build vendor relationships and create an efficient supply chain, the supplier scorecard can be a valuable tool. It helps the procurement department evaluate and compare supplier relationships based on set criteria derived from specific business needs.

A well-defined supplier scorecard not only gives the procurement team a ranking system to analyze suppliers but it is also a tool to build supplier relationships through collaboration—both as you create the scorecard and as suppliers use it to improve. The best sourcing/supplier relationships tap into this deeper impact a supplier scorecard can have.

How to Create Winning a Supplier Scorecard

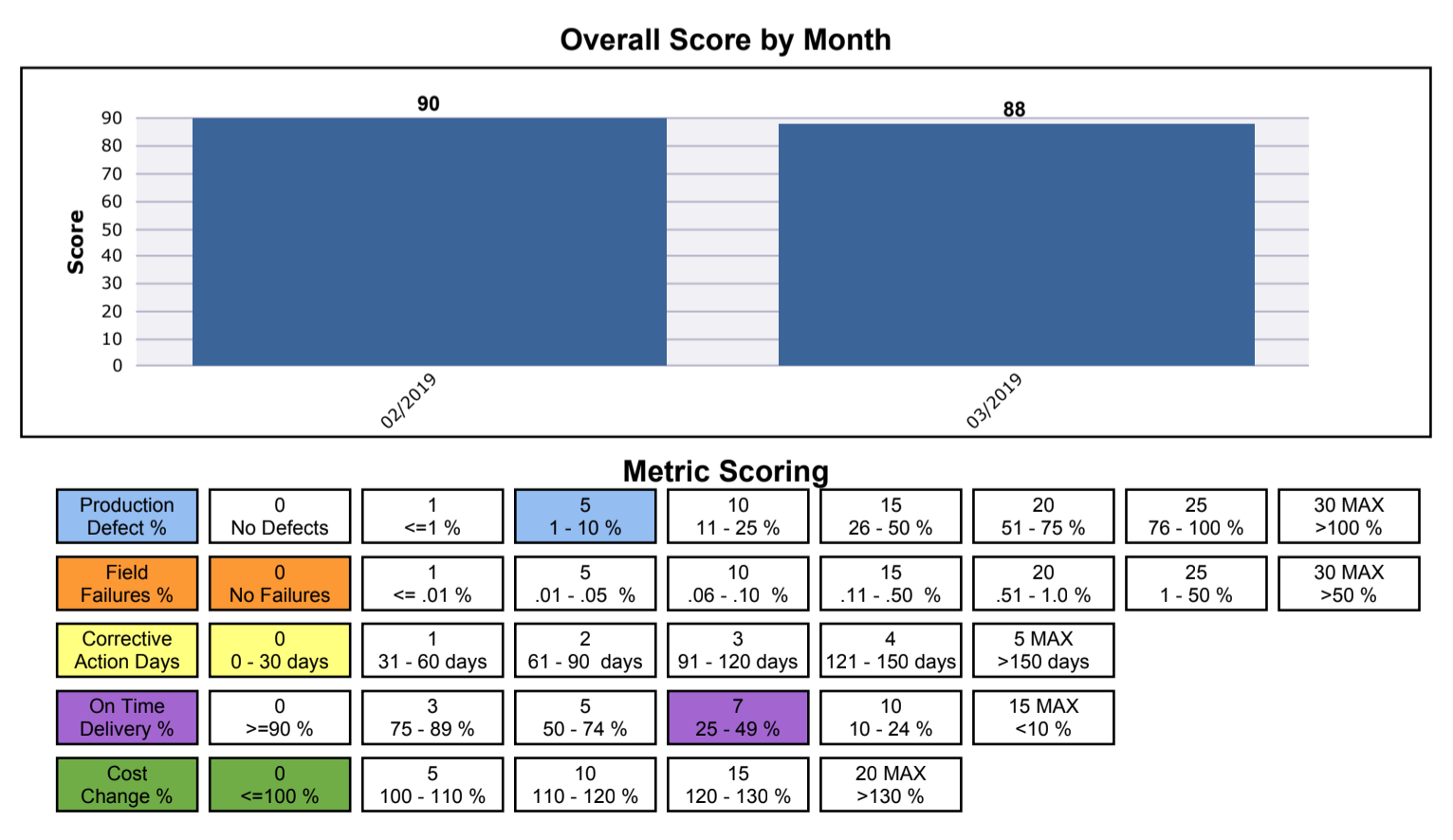

As you create or rework a scorecard, start with the metrics that matter most to your team. Select KPIs that measure your suppliers’ performance and also support your goals. KPIs that are frequently used in excellent supplier scorecards include:

-

- Price variance

- Lead-time variance

- On-time variance

- PO quantity variance

- Quality variance

- Production defects

- Field failures

- Corrective action

Because your supplier scorecard reflects what’s important to your company, the categories you include might vary. Some companies include elements such as supplier communication and innovation. This can incentivize the supplier to look for additional ways to add value or emphasizes good communication.

Collaborating with Suppliers on the Scorecard

After working internally to define the metrics that indicate success on a larger scale for your business, approach your suppliers and include them in the process.

Start by scheduling a call with your suppliers to walk through the metrics and your expectations.

Then work with them to finalize the key performance indicators (KPIs) in the scorecard and answer any questions.

This is an important step as it makes it a conversation, not an attack. It shows that you trust their analysis and value their opinions. This gives them a chance to be a part of the conversation and work with you based on their experiences as well. Through this conversation you can also lay out clear expectations and the action steps that will result from specific scores.

Communicate Regularly about the Results

Once you have finalized and shared the supplier scorecard, maintain it and schedule monthly or quarterly calls to discuss the results with your suppliers. This investment shows that you care about the long-term partnership, not just the immediate results they provide.

Maintain your scorecard and schedule monthly or quarterly calls to discuss the results with your suppliers.

Make it clear that suppliers can inform you if there are any inaccuracies—after all, mistakes happen, especially with data entry! It’s a reflection of their performance. The best suppliers take their scorecards very seriously and focus on the grade they receive.

Supplier scorecards help manage expectations between buyers and suppliers, increasing transparency and giving clear direction on areas to improve. But they can do so much more for your business – building long-term relationships with suppliers and encouraging them to partner with you for the success of both parties.

Learn how Altraco can help you meet the challenges of overseas manufacturing. If you have more questions, feel free to contact our team of overseas manufacturing experts.

Al is an entrepreneur, founder, and owner of multiple businesses, including Altraco, an outsourcing and contract manufacturing company. Working across multiple continents and trusted by Fortune 500 companies, Al finds innovative solutions to traditional supply chain challenges. He is a member of Vistage Worldwide.